Carbon material used for lithium-sulfur battery and preparation thereof, and applications

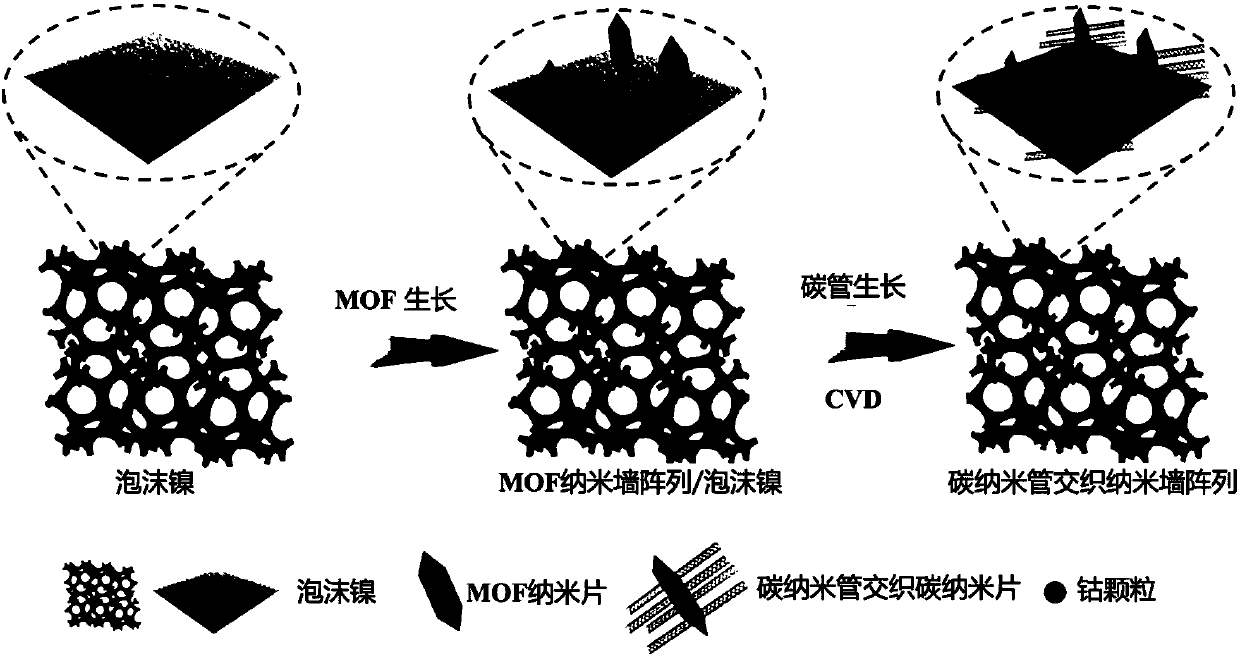

A lithium-sulfur battery and carbon material technology, applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problem that the sulfur load is difficult to meet the actual demand, the utilization rate of active materials is reduced, and the transmission of electrons and ions is limited, etc. problem, to achieve the effect of shortening the ion transmission distance, promoting infiltration, and smooth electron transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

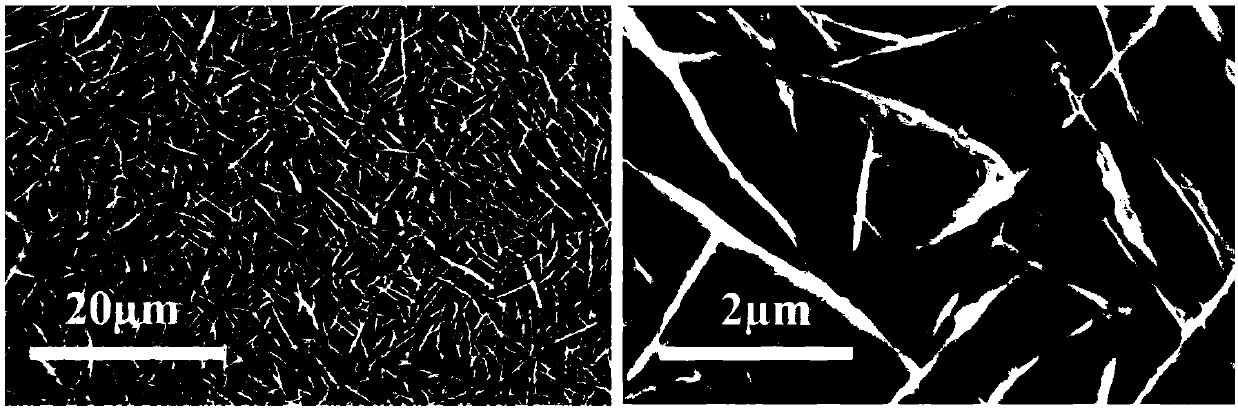

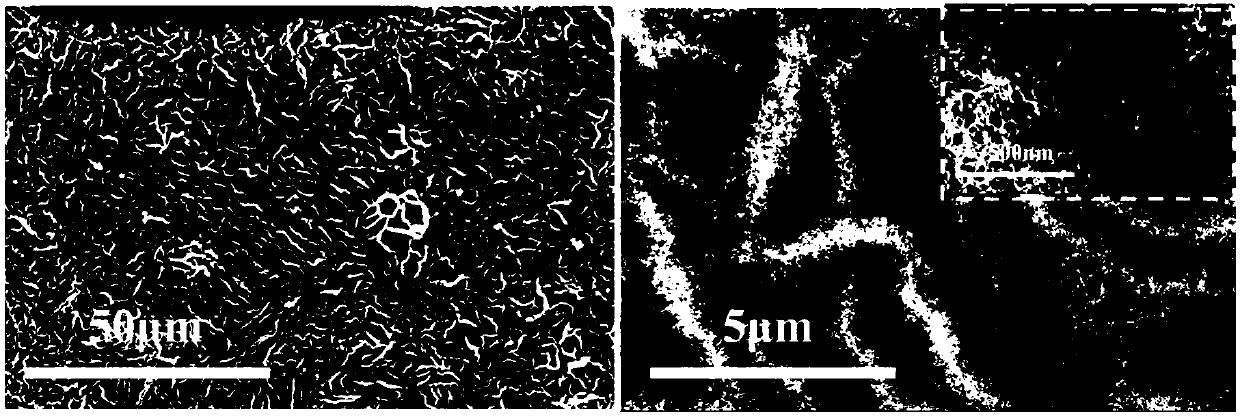

[0048] Take 3 pieces of 2cm*4cm nickel foam and place them in 3M HCl solution, ultrasonicate at room temperature for 30 minutes, wash with deionized water for 3 times, then transfer to 30mL methanol and 3mL dissolved in 0.075M zinc nitrate and 0.25M hexamethylenetetramine 2M nitric acid mixed solution, sealed in a hydrothermal reaction kettle and heated in an oven at 60°C for 48h. After cooling to room temperature, wash the foamed nickel sheet 3 times with water, then immerse it in 250mL of 0.01M 2-methylimidazole aqueous solution, let it stand for 6h, wash it with water 3 times, and then immerse it in 40mL of 0.5M cobalt nitrate methanol solution, let stand for 24h. The product obtained in this step was washed 3 times with methanol, and then dried in an oven at 60° C. for 2 h. Subsequently, it was transferred to a tube furnace under Ar (100 mLmin -1 ) and H 2 (10mLmin -1 ) in a mixed atmosphere at 20°C min -1 The heating rate was increased to 550 °C. After keeping the t...

Embodiment 2

[0051] Take 3 pieces of 2cm*4cm aluminum foil and put them in 3M HCl solution, sonicate at room temperature for 30 minutes, wash with deionized water for 3 times, then transfer to 30mL of methanol and 3mL of 2M nitric acid mixed solution, sealed in a hydrothermal reaction kettle and heated in an oven at 60°C for 48h. After cooling to room temperature, the obtained aluminum foil was washed with water three times, then immersed in 250mL of 0.01M 2-methylimidazole aqueous solution, after standing for 6h, washed with water for three times, and then immersed in 40mL of 0.5M cobalt nitrate in methanol Solution, let stand for 24h. The product obtained in this step was washed 3 times with methanol, and then dried in an oven at 60° C. for 2 h. Subsequently, it was transferred to a tube furnace under Ar (100 mLmin -1 ) and H 2 (10mLmin -1 ) in a mixed atmosphere at 20°C min -1 The heating rate was increased to 550 °C. After keeping the temperature at 550°C for 10 minutes, pass int...

Embodiment 3

[0054] Take 3 pieces of 2cm*4cm nickel foam and place them in 3M HCl solution, ultrasonicate at room temperature for 30 minutes, wash with deionized water for 3 times, then transfer to 30mL methanol and 3mL dissolved in 0.075M zinc nitrate and 0.25M hexamethylenetetramine 2M nitric acid mixed solution, sealed in a hydrothermal reaction kettle and heated in an oven at 60°C for 48h. After cooling to room temperature, wash the foamed nickel sheet 3 times with water, then immerse it in 250mL of 0.01M 2-methylimidazole aqueous solution, let it stand for 6h, wash it with water 3 times, and then immerse it in 40mL of 0.5M cobalt nitrate methanol solution, let stand for 24h. The product obtained in this step was washed 3 times with methanol, and then dried in an oven at 60° C. for 2 h. Subsequently, it was transferred to a tube furnace under Ar (100 mLmin -1 ) and H 2 (10mLmin -1 ) in a mixed atmosphere at 20°C min - Raise the temperature to 950°C, keep the temperature for 1 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com