Composite material of ionic liquid functionalized carbon nanotubes and preparation method of composite material

A carbon nanotube and ionic liquid technology, which is applied to the preparation of ionic liquid functionalized carbon nanotube materials, and the field of ionic liquid functionalized carbon nanotube composite materials, can solve complex synthesis conditions, large energy consumption, and no obvious catalytic performance. Questions such as questions are raised to achieve the effect of simple and fast process and lower cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 Preparation of Ionic Liquid Functionalized Carbon Nanotubes

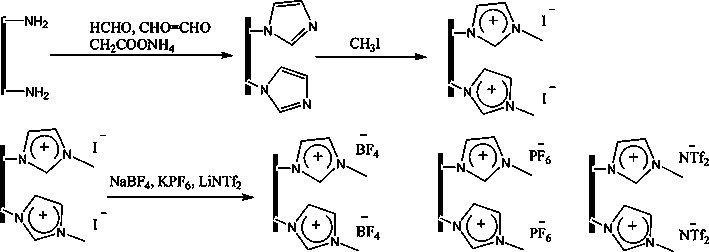

[0020] Schematic diagram of the preparation steps of methylimidazolium-based ionic liquid functionalized carbon nanotubes as figure 1 As shown, the specific steps are as follows:

[0021] 1) The formaldehyde and glyoxal solution were ultrasonically mixed according to the molar ratio of 1:1, and then ammonium acetate and amine-functionalized carbon nanotubes were added. o C methanol for 6 hours. The initial product was washed with (0.1 M) sodium hydroxide solution to obtain imidazole functionalized carbon nanotubes; wherein the molar ratio of ammonium acetate to formaldehyde was 1:2;

[0022] 2) Add the above-mentioned imidazole functionalized carbon nanotubes into the methyl iodide solution, at 80 o C methanol reacted for 6 hours, and finally obtained methylimidazolium iodide salt ionic liquid functionalized carbon nanotubes MIM-I-CNTs; wherein the mass ratio of imidazole functionalized carbon na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com