Preparation method of multifunctional asphalt stripping agent

A stripping agent and multi-functional technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of harsh synthesis conditions, poor hydrolysis resistance, poor compatibility of asphalt, etc., achieve mild synthesis process conditions and prolong service life , anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

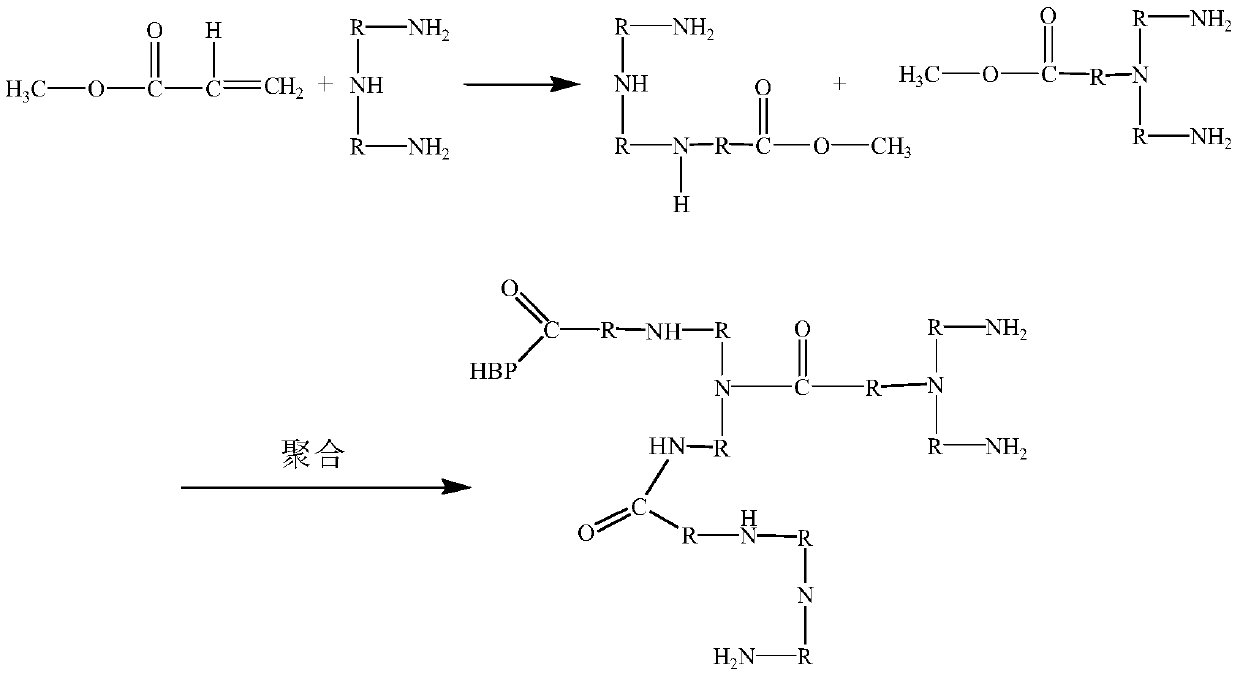

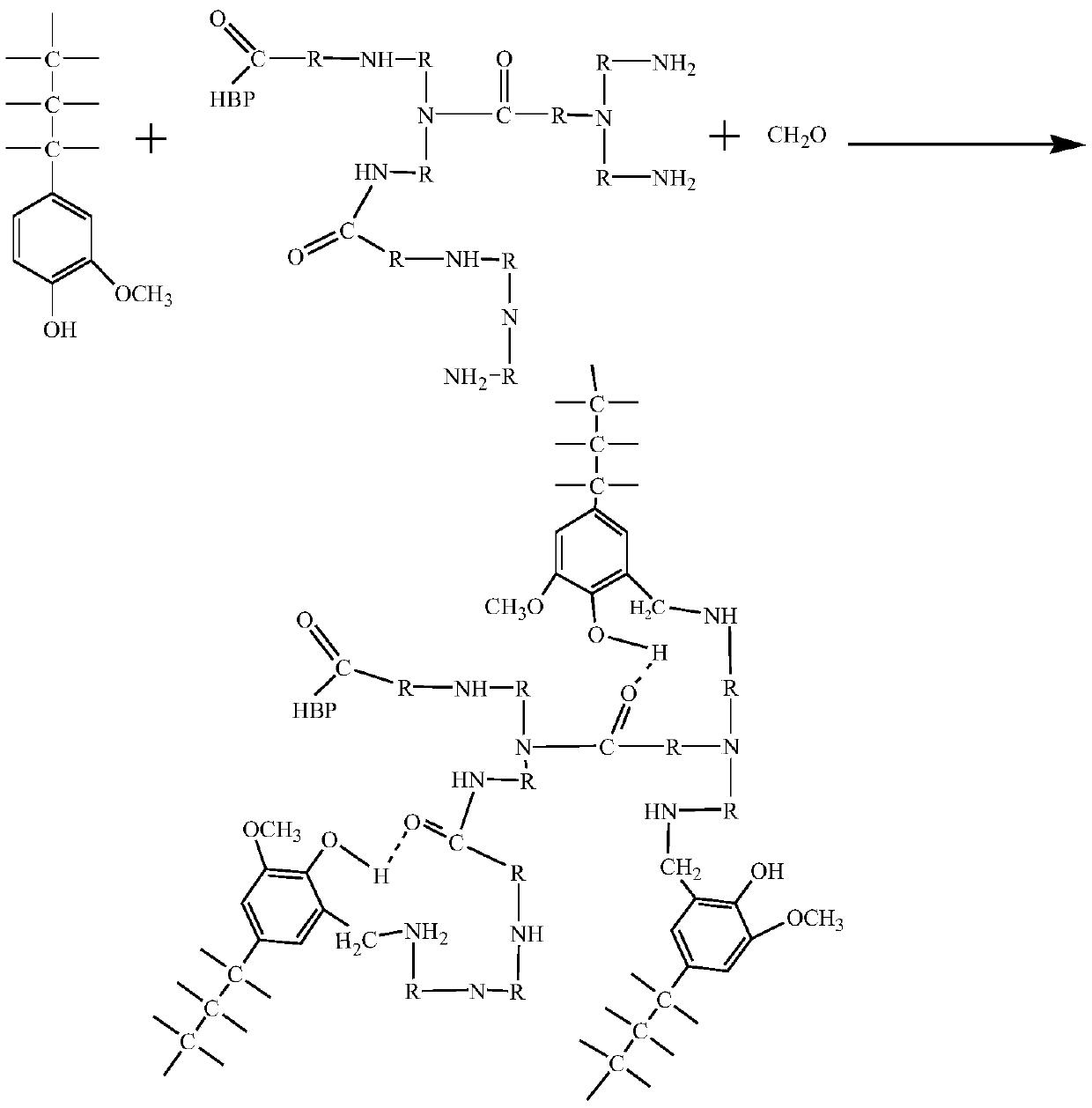

Method used

Image

Examples

Embodiment 1

[0038] High purity N 2 Under protection, diethylenetriamine (51.59g, 0.5mol) was placed in a 250ml three-necked flask, and methyl acrylate (47.36g, 0.55mol) and methanol (35.23g, 1.1mol) were added dropwise with a constant pressure funnel. The mixed solution was mechanically stirred at 0°C and added dropwise for 2 hours. After the dropwise addition was completed, it was stirred at room temperature for 3 hours to obtain a light yellow transparent liquid, which was placed in a rotary evaporator, and methanol was removed at 45°C and -0.85MPa until no methanol flowed out. , continue to heat up to 145 ° C, -0.85 MPa polycondensation reaction for 3 hours, and finally get 75.58 g of yellow viscous liquid NH 2 -HBP;

[0039] Take 4.500g of wheatgrass alkali lignin and add it into 9g of water and stir to dissolve it, and make it into an aqueous solution of wheatgrass alkali lignin, which is recorded as solution A; take the above 15.00g of NH 2 -HBP is added with 41.00g water and stir...

Embodiment 2

[0042] High purity N 2 Under protection, triethylenetetramine (73.12g, 0.5mol) was placed in a 250ml three-necked flask, and methyl acrylate (51.66g, 0.6mol) and (methanol 38.44g, 1.2mol) were added dropwise with a constant pressure funnel. The mixed solution was mechanically stirred at 0°C and added dropwise for 2 hours. After the dropwise addition was completed, it was stirred at room temperature for 4 hours to obtain a light yellow transparent liquid, which was placed in a rotary evaporator, and methanol was removed at 50°C and -0.85MPa until no methanol flowed out. Continue to heat up to 145 ° C, -0.85 MPa polycondensation reaction for 4 hours, and finally obtain 87.58 g of yellow viscous liquid NH 2 -HBP;

[0043] Take 6.00g of wheatgrass alkali lignin and add it into 15g of water and stir to dissolve it, and make it into an aqueous solution of wheatgrass alkali lignin, which is recorded as solution A; take the above 15.00g of NH 2 -HBP is added with 30.00g water and st...

Embodiment 3

[0046] Under nitrogen protection, ethylenediamine (30.05g, 0.5mol) was placed in a 250ml three-necked flask, and methyl acrylate (47.328g, 0.58mol) and methanol (37.15g, 1.16mol) were added dropwise with a constant pressure funnel The mixed solution was mechanically stirred at 0°C and added dropwise for 2 hours. After the dropwise addition was completed, it was mechanically stirred at room temperature for 5 hours to obtain a light yellow transparent liquid, which was placed in a rotary evaporator, and methanol was removed at 45°C and -0.85MPa until no methanol flowed out. Continue to heat up to 145 ° C, -0.85 MPa polycondensation reaction for 2 hours, and finally get 56.23 g of yellow viscous liquid NH 2 -HBP;

[0047] Take 7.500g of wheatgrass alkali lignin and add it into 7.5g of water and stir to dissolve it, and make it into an aqueous solution of wheatgrass alkali lignin, which is recorded as solution A; take the above 15.00g of NH 2 -HBP is added with 75.00g water and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com