Anti-deformation and high-supporting EVA (Ethylene Vinyl Acetate) foaming material as well as preparation method and application thereof

A foam material and anti-deformation technology, applied in applications, soles, clothing, etc., can solve problems such as poor comfort, anti-deformation ability and decreased support, and achieve reduced compression deformation, high support stability, and excellent The effect of resistance to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Embodiments of the present invention provide a method for preparing the anti-deformation high-support EVA foam material as described above, comprising the following steps:

[0055] The EVA composite material is sequentially mixed and granulated, and then foamed to obtain an anti-deformation high-support EVA foam material.

[0056] The process flow of the embodiment of the present invention mainly includes: weighing→mixing→granulation→foaming→baking. In the embodiment of the present invention, first group and weigh: according to the dosage of the formula, the main plastic materials such as EVA / POE / OBC / SEBS can be weighed as the first group, and the KEVLAR aramid fiber and silane coupling agent can be weighed as the second group. Stearic acid, zinc stearate, and zinc oxide are weighed as the third group; DCP and blowing agent are weighed as the fourth group.

[0057] In the embodiment of the present invention, the weighed components are mixed: first, the first group of m...

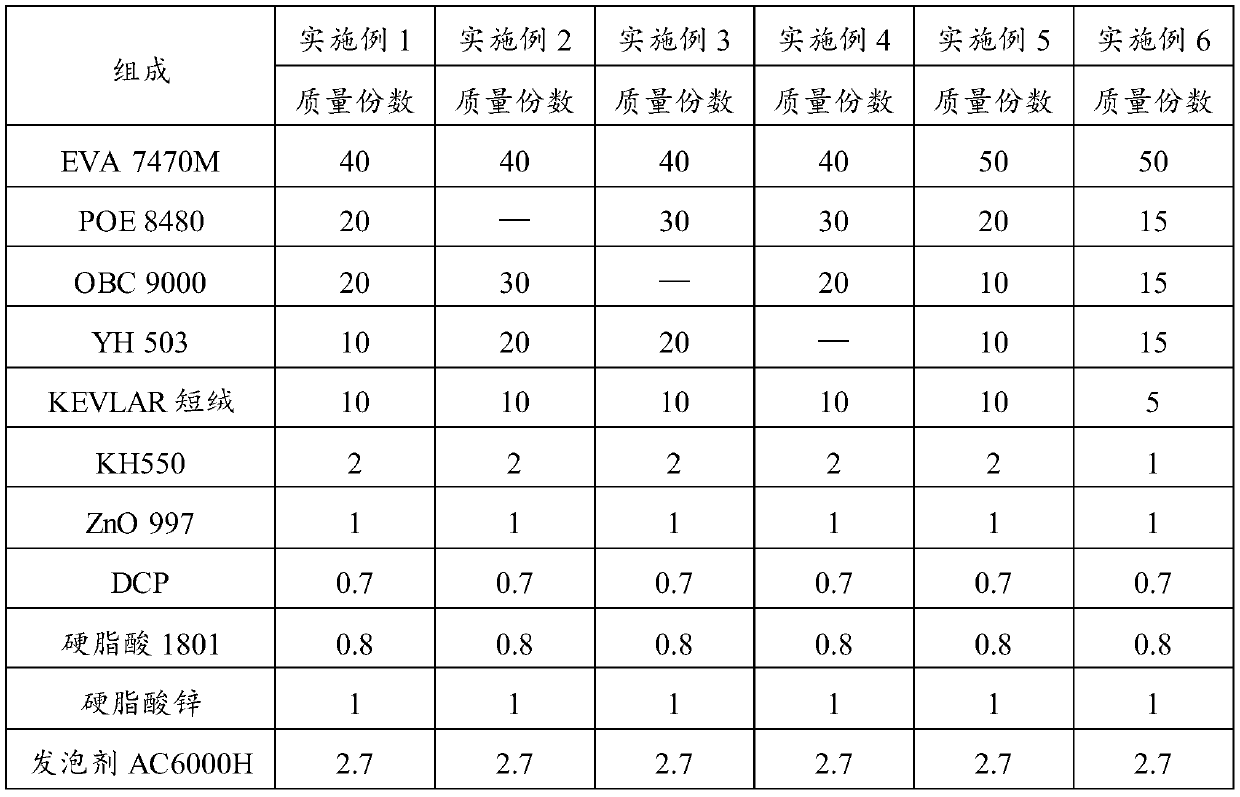

Embodiment 1

[0065] Weighing: According to the dosage of the formula in Table 1, the main plastic materials such as EVA / POE / OBC / SEBS are weighed as the first group, KEVLAR aramid fiber and silane coupling agent are weighed as the second group, stearic acid, Zinc stearate and zinc oxide are named for the third group; DCP and blowing agent are named for the fourth group.

[0066] Mixing: first pour the first group of materials into the internal mixer, and start the machine, when the temperature rises to 90-95 ° C, then pour the second group of materials; when the temperature rises to 95-100 ° C, pour The third group of materials; when the temperature rises to 100-110°C, pour in the fourth group of materials, and after mixing for 5 minutes, pour out the mixed materials.

[0067] Material making: Pour the mixed material into the material making machine, and adjust the temperature of the first, second, third, and fourth zones to 75, 80, 85, and 90°C respectively. And, the screw speed is adjust...

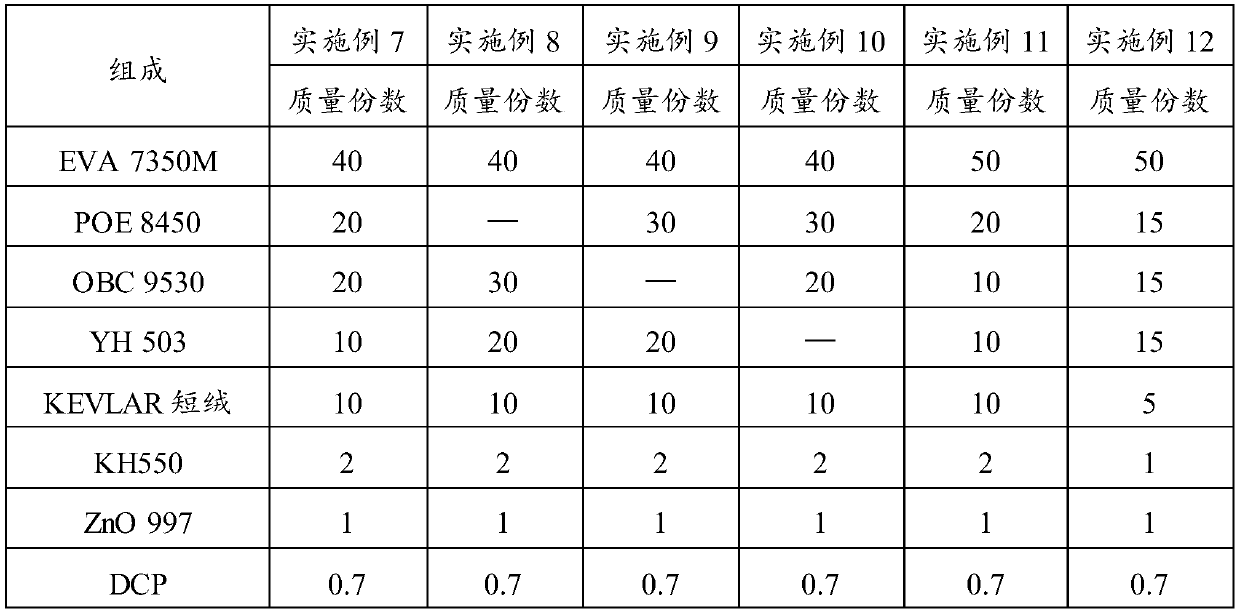

Embodiment 2-12

[0071] According to the steps of Example 1, the formulations are as shown in Table 1 and Table 2, respectively to prepare anti-deformation high-support EVA foam materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com