Temporary steel protective coating and preparation method thereof

A temporary protection and coating technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as slow corrosion, potential safety hazards in buildings, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A temporary protective coating for steel, which is composed of the following components in weight percent: 20% ethyl orthosilicate, 3% methyltrimethoxysilane, 35% water, 0.01% acid catalyst, 36.99% hexanediol, silane Coupling agent 5%. Wherein the acid catalyst is a mixed solution of hydrochloric acid and acetic acid in a volume ratio of 1:1, and the silane coupling agent is 3-aminopropyltriethoxysilane and 3-glycidyloxypropyltrimethoxysilane in a mass ratio of 1 :2 Mixed mixture.

[0016] During the preparation of the steel temporary protective coating, mix ethyl orthosilicate, methyltrimethoxysilane, hexanediol, and silane coupling agent in the reactor, then add water and acidic catalyst into the reactor, and mix well , without layering and standing still for a week, a temporary protective coating for steel can be prepared.

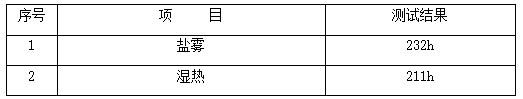

[0017] After drying the samples at room temperature for 7 days, the test performance is as follows:

[0018]

Embodiment 2

[0020] A temporary protective coating for iron and steel, which is composed of the following components in weight percentage: 10% ethyl orthosilicate, 8% methyltriethoxysilane, 50% water, 0.001% acid catalyst, 30.999% ethanol, silane Joint agent 1%. Wherein the acid catalyst is a mixed solution of hydrochloric acid and acetic acid in a volume ratio of 1:1, and the silane coupling agent is 3-aminopropyltriethoxysilane and 3-glycidyloxypropyltrimethoxysilane in a mass ratio of 1 :1 Mixed mixture.

[0021] During the preparation of the steel temporary protective paint, ethyl orthosilicate, methyltriethoxysilane, ethanol, and silane coupling agent are mixed in the reactor, and then water and an acidic catalyst are added to the reactor and mixed evenly. Temporary protective coatings for steel can be prepared without delamination and standing still for a week.

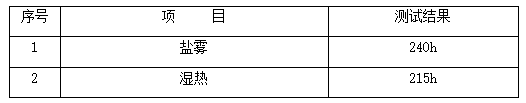

[0022] After drying the samples at room temperature for 7 days, the test performance is as follows:

[0023]

Embodiment 3

[0025] A temporary protective coating for iron and steel, which is composed of the following components in weight percentage: 15% orthoethyl silicate, 5% vinyltriethoxysilane, 40% water, 0.005% acid catalyst, 36.995% methanol, silane Joint agent 3%. Wherein the acid catalyst is a mixed solution of hydrochloric acid and acetic acid in a volume ratio of 1:1, and the silane coupling agent is 3-aminopropyltriethoxysilane and 3-glycidyloxypropyltrimethoxysilane in a mass ratio of 1 :2 Mixed mixture.

[0026] During the preparation of the steel temporary protective paint, tetraethyl orthosilicate, vinyltriethoxysilane, methanol and silane coupling agent are mixed in the reactor, and then water and acidic catalyst are added to the reactor and mixed evenly. Temporary protective coatings for steel can be prepared without delamination and standing still for a week.

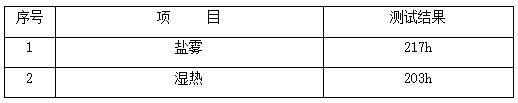

[0027] After drying the samples at room temperature for 7 days, the test performance is as follows:

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com