A kind of dopamine/polyetheramine multilayer modified carbon fiber and its preparation method

A multi-layer modification and carbon fiber technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problem that high strength and high toughness of carbon fiber composite materials cannot exist at the same time, achieve good economic benefits and industrial application prospects, low cost, general fitness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Step 1. Carbon fiber surface cleaning

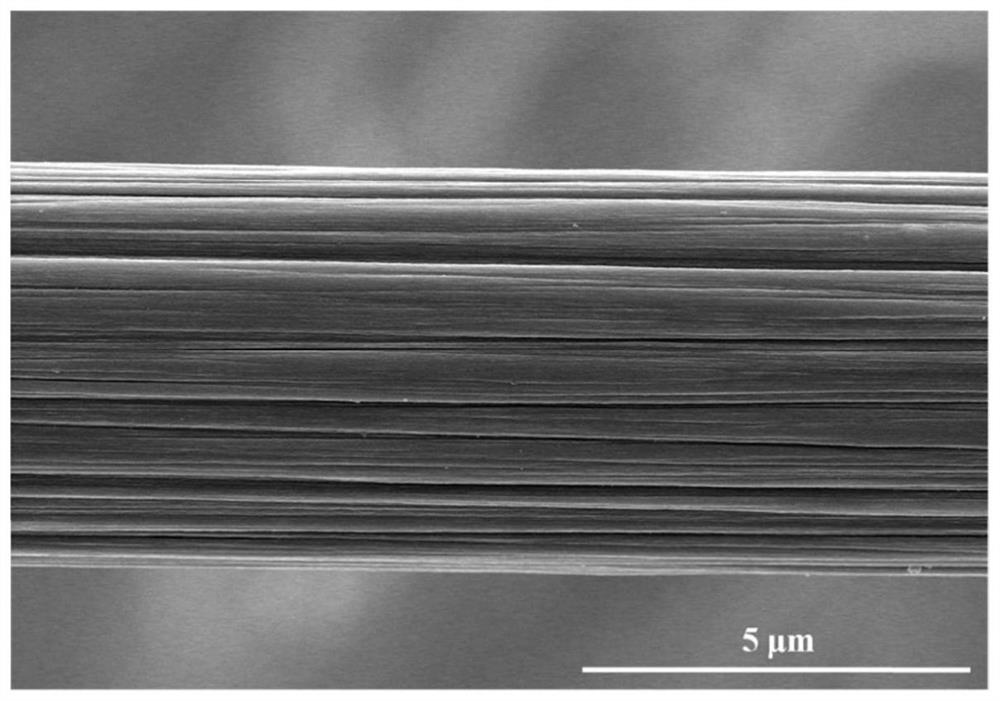

[0045] Using acetone as a solvent, the high-strength polyacrylonitrile-based carbon fiber was condensed and refluxed at 70°C for 24 hours by Soxhlet extraction, and then dried at 60°C to obtain the cleaned carbon fiber. figure 1 ;

[0046] Step 2, Tris buffer preparation

[0047] Thoroughly mix Tris and deionized water with ultrasonic vibration for 5 minutes at a mass ratio of 1:1000, then slowly add 1mol / L hydrochloric acid solution into the mixture of Tris and deionized water to adjust The pH value of the solution was 8 and ultrasonically oscillated for 5 minutes to obtain tris buffer solution;

[0048] Step 3, preparation of polyetheramine solution

[0049] Take 0.1g of polyetheramine with a molecular weight of 400 and add it to 100ml of organic solvent dimethylformamide, ultrasonically shake for 10min and mix thoroughly;

[0050] Step 4, preparation of carbon fiber surface polydopamine layer

[0051] Immerse the cleaned car...

Embodiment 2

[0057] Step 1. Carbon fiber surface cleaning

[0058] Using acetone as a solvent, the high-strength polyacrylonitrile-based carbon fiber was condensed and refluxed at 75°C for 36 hours by Soxhlet extraction method, and then dried at 70°C;

[0059] Step 2, Tris buffer preparation

[0060] Thoroughly mix Tris and deionized water with ultrasonic vibration for 7 minutes at a mass ratio of 1.2:1000, then slowly add 1.5 mol / L hydrochloric acid solution into the mixture of Tris and deionized water, Adjust the pH value of the solution to 8.5 and ultrasonically vibrate for 7 minutes to obtain tris buffer solution;

[0061] Step 3, preparation of polyetheramine solution

[0062] Take 0.12g of polyetheramine with a molecular weight of 400 and add it to 150ml of organic solvent ethanol, ultrasonically shake for 15min and mix thoroughly;

[0063] Step 4, preparation of carbon fiber surface polydopamine layer

[0064] Immerse the cleaned carbon fibers in 130ml tris buffer solution by di...

Embodiment 3

[0071] Step 1. Carbon fiber surface cleaning

[0072] Using acetone as a solvent, the high-strength polyacrylonitrile-based carbon fiber was condensed and refluxed at 80°C for 48 hours by Soxhlet extraction method, and then dried at 80°C;

[0073] Step 2, Tris buffer preparation

[0074] Thoroughly mix Tris and deionized water with ultrasonic vibration at a mass ratio of 2:1000 for 10 minutes, then slowly add 2mol / L hydrochloric acid solution into the mixture of Tris and deionized water to adjust The pH value of the solution was 9 and ultrasonically oscillated for 10 minutes to obtain tris buffer solution;

[0075] Step 3, preparation of polyetheramine solution

[0076] Take 0.2g of polyetheramine with a molecular weight of 400 and add it to 200ml of organic solvent tetrahydrofuran, ultrasonically shake for 30min and mix thoroughly;

[0077] Step 4, preparation of carbon fiber surface polydopamine layer

[0078] Immerse the cleaned carbon fiber in 200ml of tris buffer by d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com