A kind of wet preparation method of instant quinoa nutrition snow flakes

A technology for snowflakes and quinoa, applied in the field of food processing, can solve the problems of reducing the nutritional value of grain powder, affecting starch gelatinization characteristics, weakening the flavor of grain powder, etc. The effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the present embodiment, the process steps of preparing instant quinoa nutritional snow flakes are as follows:

[0039] (1) Raw material pretreatment

[0040] Pick out bad and bad grains from the prepared raw dry quinoa grains to obtain dry quinoa grains with normal color, no mildew, no peculiar smell, and no moth-eaten;

[0041] (2) Immersion

[0042] Measure 50 kilograms of dry quinoa grains for soaking from the pretreated dry quinoa grains in step (1), put them into a stirring tank, add tap water, soak them at room temperature (30°C) for 3 hours under stirring, and stir. The speed is 2r / min, and the added amount of the tap water is measured by the weight of the soaked quinoa as 120 kg. After the soaking time is reached, the soaked quinoa is rinsed with tap water (the time is 2 to 5 min) to remove the surface of the quinoa. saponins;

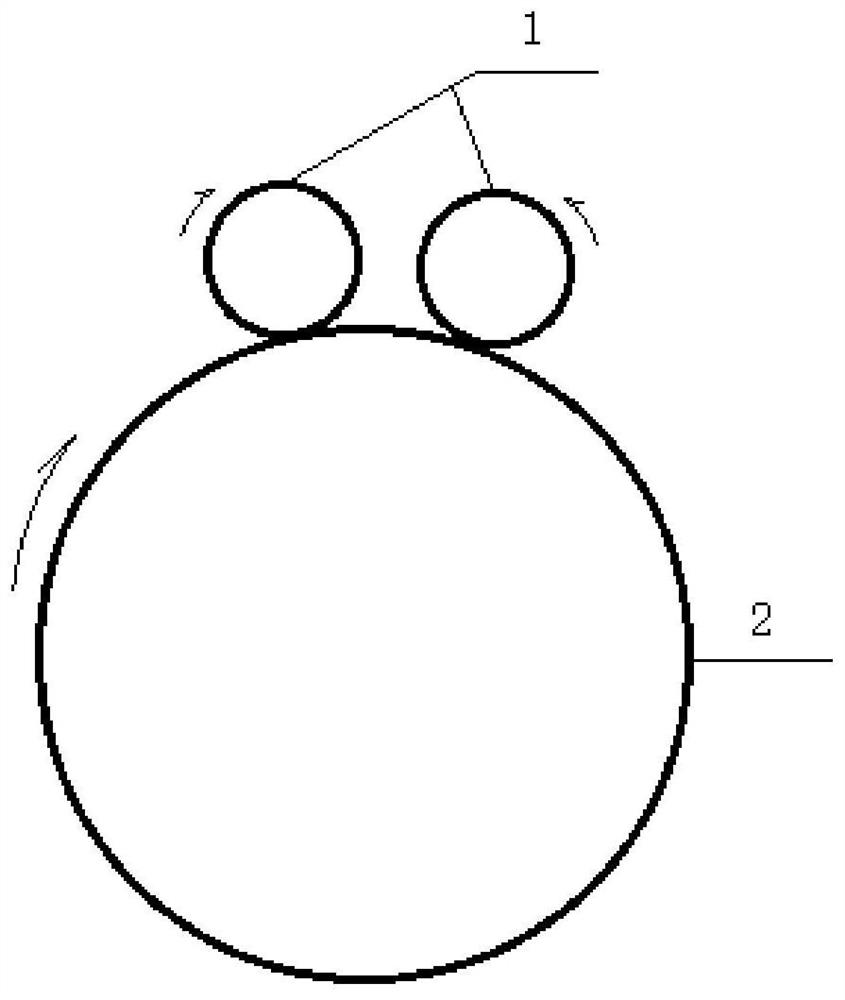

[0043] (3) Refining

[0044] The soaked quinoa grains are sent to the colloid abrasive hopper for refining by the colloid mill, ...

Embodiment 2

[0058] In the present embodiment, the process steps of preparing instant quinoa nutritional snow flakes are as follows:

[0059] (1) Raw material pretreatment

[0060] Pick out the bad grains and bad grains from the prepared raw dry quinoa grains to obtain dry quinoa grains with normal color, no mildew, no peculiar smell, and no moth-eaten;

[0061] (2) Immersion

[0062] Measure 50 kilograms of dry quinoa grains for soaking from the pretreated dry quinoa grains in step (1), put them into a soaking tank, add distilled water, and soak them at room temperature (20° C.) for 5 hours. The distilled water The added amount of quinoa after soaking is measured as 100 kilograms, and after the soaking time is reached, the soaked quinoa is rinsed with distilled water (the time is 2 to 5 min) to remove the saponins on the surface of the quinoa;

[0063] (3) Refining

[0064] The soaked quinoa grains are sent to the colloid abrasive hopper for refining by the colloid mill, the distance b...

Embodiment 3

[0078] In the present embodiment, the process steps of preparing instant quinoa nutritional snow flakes are as follows:

[0079] (1) Raw material pretreatment

[0080] Pick out the bad grains and bad grains from the prepared raw dry quinoa grains to obtain dry quinoa grains with normal color, no mildew, no peculiar smell, and no moth-eaten;

[0081] (2) Immersion

[0082] Measure 50 kilograms of dry quinoa grains for soaking from the pretreated dry quinoa grains in step (1), put them into a soaking tank, add mineral water, and soak them at room temperature (25° C.) for 4 hours. The amount of mineral water added is measured by the weight of the soaked quinoa as 140 kg. After the soaking time is reached, the soaked quinoa is rinsed with mineral water (the time is 2 to 5 minutes) to remove the saponins on the surface of the quinoa;

[0083] (3) Refining

[0084] The soaked quinoa grains are sent to the colloid abrasive hopper for refining by the colloid mill, the distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com