Washing method of ferric phosphate

A washing method and iron phosphate technology, which are applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as labor intensity, poor quality stability, and difficult wastewater treatment, so as to improve product quality, stability, The effect of avoiding the difficulty of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

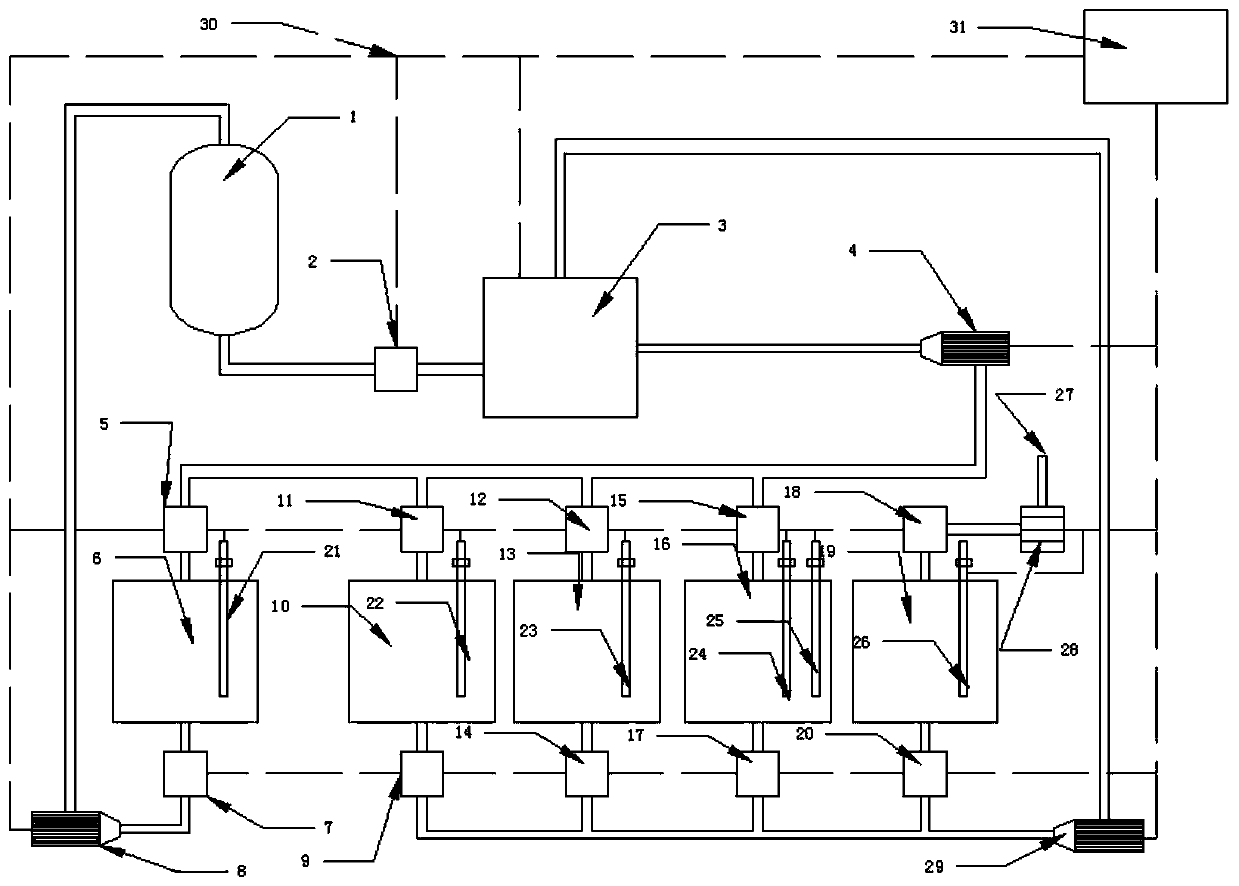

Method used

Image

Examples

Embodiment 1

[0036] A method for washing ferric phosphate, comprising the steps of:

[0037]First set the initial temperature of the hot pure water heated by the steam heater on the DCS system to 45°C, the high and low liquid level values of the water tanks and washing liquid reuse tanks at all levels, and control the four levels through the high and low liquid level values of the water tanks at all levels The mass ratio of the total water in the water tank to the iron phosphate material (calculated as dry powder) is 80:1, and the upper limit of the conductivity of the washing water and washing liquid in the third-level water tank is 400us / cm.

[0038] S1. First-level washing: After the setting is completed, let the DCS automatically run the iron phosphate washing program. The DCS system controls the discharge solenoid valve of the aging kettle to transfer the aged iron phosphate material to the fully automatic vertical filter press, and the filtration process is performed first. , a...

Embodiment 2

[0045] A method for washing ferric phosphate, comprising the steps of:

[0046] First set the initial temperature of the hot pure water heated by the steam heater on the DCS system to 20°C, the high and low liquid level values of the water tanks at all levels and the washing liquid reuse tank, and control the four levels through the high and low liquid level values of the water tanks at all levels The mass ratio of the total water in the water tank to the iron phosphate material (calculated as dry powder) is 80:1, and the upper limit of the conductivity of the washing water and washing liquid in the third-level water tank is 400us / cm.

[0047] S1. First-level washing: After the setting is completed, let the DCS automatically run the iron phosphate washing program. The DCS system controls the discharge solenoid valve of the aging kettle to transfer the aged iron phosphate material to the fully automatic vertical filter press, and the filtration process is performed first. ...

Embodiment 3

[0054] A method for washing ferric phosphate, comprising the steps of:

[0055] First set the initial temperature of the hot pure water heated by the steam heater on the DCS system to 30°C, the high and low liquid level values of the water tanks and the washing liquid reuse tanks at all levels, and control the four levels through the high and low liquid level values of the water tanks at all levels The mass ratio of the total water volume of the water tank to the iron phosphate material (calculated as dry powder) is 20:1, and the upper limit of the conductivity of the washing water and washing liquid in the third-level water tank is 400us / cm.

[0056] S1. First-level washing: After the setting is completed, let the DCS automatically run the iron phosphate washing program. The DCS system controls the discharge solenoid valve of the aging kettle to transfer the aged iron phosphate material to the fully automatic vertical filter press, and the filtration process is performed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com