A kind of high and low temperature resistant gel electrolyte supercapacitor and preparation method thereof

A gel electrolyte, supercapacitor technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of low electrochemical window, limited use range, narrow use temperature range, etc. High conductivity, reduced interface resistance, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

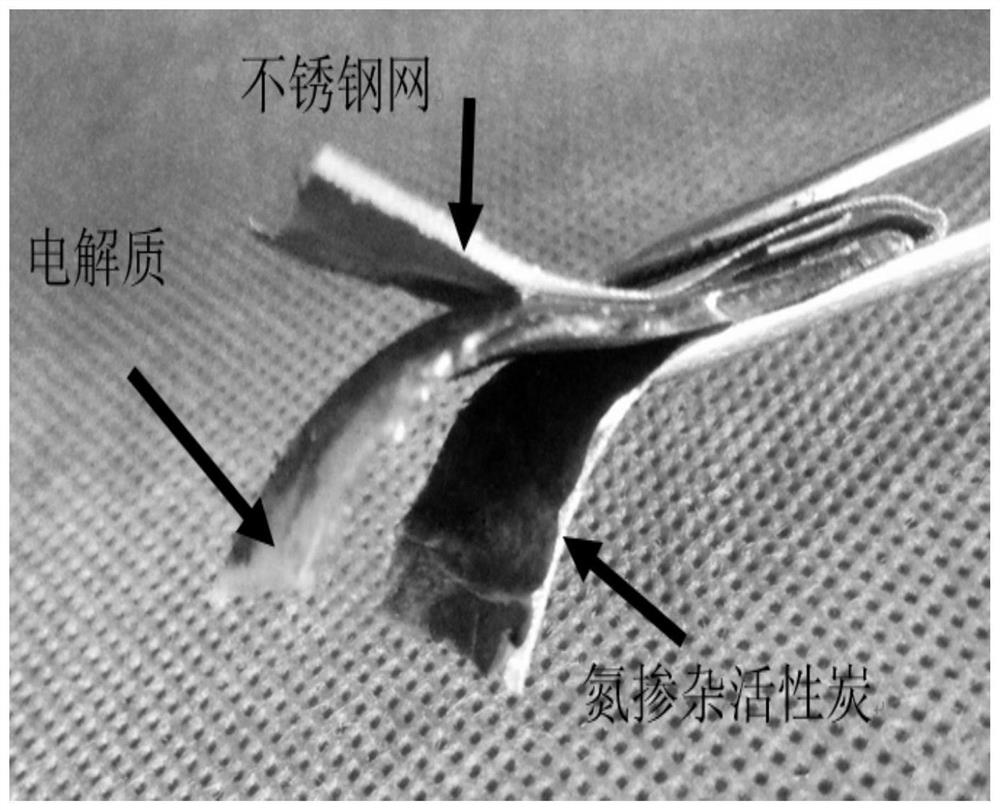

[0039] A preparation method of a high and low temperature resistant gel electrolyte supercapacitor, comprising the following steps:

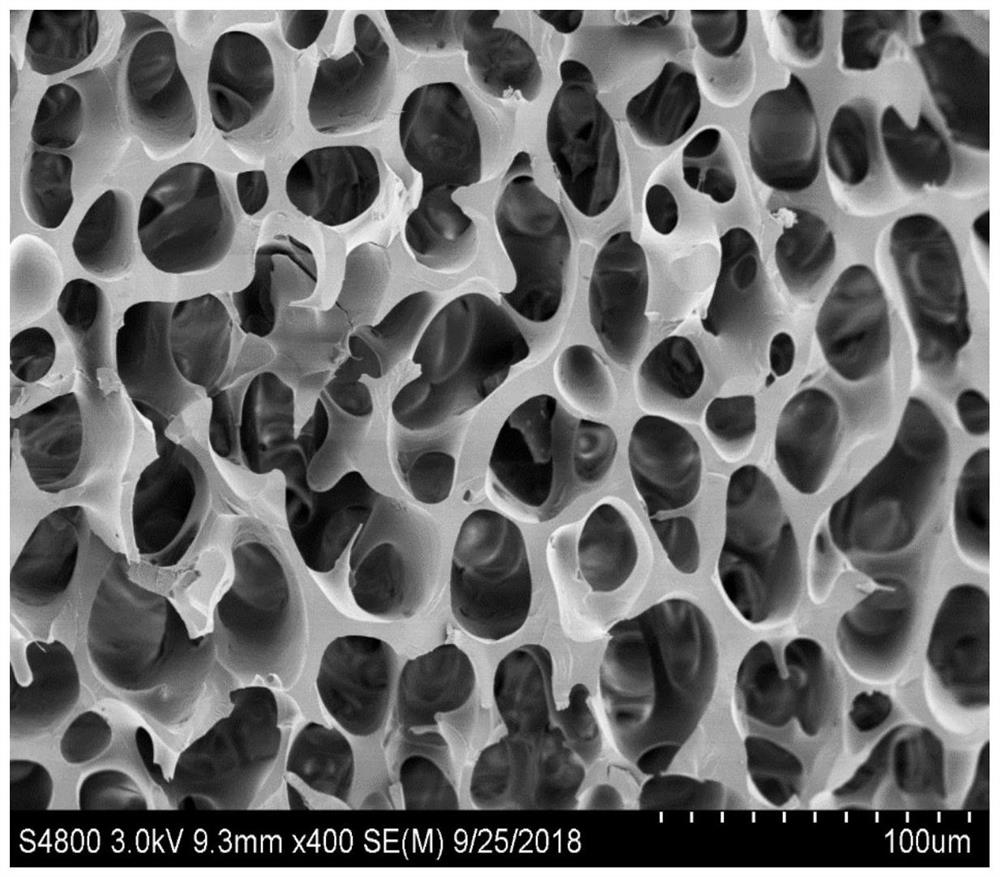

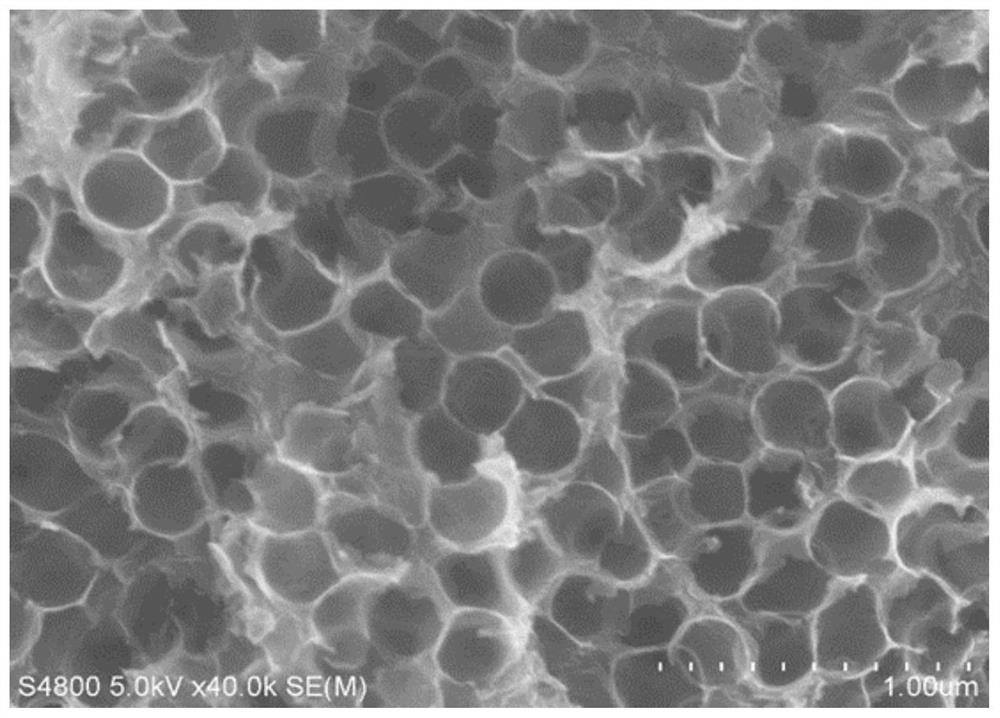

[0040] 1. Preparation of pilot hole hydrogel: first mix 0.25g of acrylamide and 0.75g of water, stir in a glass bottle, add 0.001g of N,N-methylenebisacrylamide, and freeze at low temperature after 20min Guide, add 0.0002g photoinitiator 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone, put it in the environment of -20 ℃ refrigerator for ultraviolet light polymerization, the hydrogel guide structure is as follows figure 1 As shown, it is a guided uniform porous structure.

[0041] 2. Preparation of airgel with guide holes: take the hydrogel with the above structure and freeze-dry for 72 hours.

[0042] 3. Preparation of high-concentration hydrogel: soak the prepared airgel in 5M LiTFSI for 2 hours.

[0043] 4. 6.306g of melamine (0.05mol), 10mL of formaldehyde solution (37%) and 0.021g of hexamethylenetetramine were dissolved in water (120mL...

Embodiment 2

[0052] A preparation method of a high and low temperature resistant gel electrolyte supercapacitor, comprising the following steps:

[0053] 1. Preparation of pilot hole hydrogel: first, 0.25 g of 3-[N,N-dimethyl-[2-(2-methylprop-2-enoyloxy)ethyl]ammonium]propane-1 -Mix the sulfonic acid inner salt with 0.75g water, put it in a glass bottle for stirring, add 0.001g polyethylene glycol diacrylate, conduct low temperature freezing after 20min, add 0.0005g photoinitiator α-diethoxy Acetophenone was placed in a refrigerator at -20°C for ultraviolet light polymerization.

[0054] 2. Preparation of airgel with guide holes: the hydrogel with the above structure was freeze-dried for 24 hours.

[0055] 3. Preparation of high-concentration hydrogel: soak the prepared airgel in 5M LiTFSI for 5 hours.

[0056] 4. 6.306g of melamine (0.05mol), 10mL of formaldehyde solution (37%) and 0.021g of hexamethylenetetramine were dissolved in water (120mL), and the mixture was heated to 65°C under...

Embodiment 3

[0060] A preparation method of a high and low temperature resistant gel electrolyte supercapacitor, comprising the following steps:

[0061] 1. Preparation of pilot hole hydrogel: first mix 0.25g polyethylene glycol dimethacrylate with 0.75g water, stir in a glass bottle, add 0.001g polyethylene glycol dimethacrylate, 20min Afterwards, conduct low-temperature freezing guidance, add 0.0008 g of photoinitiator α-diethoxyacetophenone, and place in a -20° C. refrigerator environment for ultraviolet light polymerization.

[0062] 2. Preparation of airgel with guide holes: take the hydrogel with the above structure and freeze-dry it for 1 hour.

[0063] 3. Preparation of high-concentration hydrogel: Soak the prepared airgel in 5M LiTFSI for 1 hour.

[0064] 4. 6.306g of melamine (0.05mol), 10mL of formaldehyde solution (37%) and 0.021g of hexamethylenetetramine were dissolved in water (120mL), and the mixture was heated to 65°C under stirring to form a transparent solution; after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com