A kind of preparation method of ionic liquid gel-based all-gel supercapacitor

A technology of supercapacitors and ionic liquids, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of no substantive breakthroughs and low energy storage of supercapacitors, and achieve recyclable Utilize recycling, improve mechanical properties, and be easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] A preparation method for an ionic liquid gel-based all-gel supercapacitor, comprising the following steps:

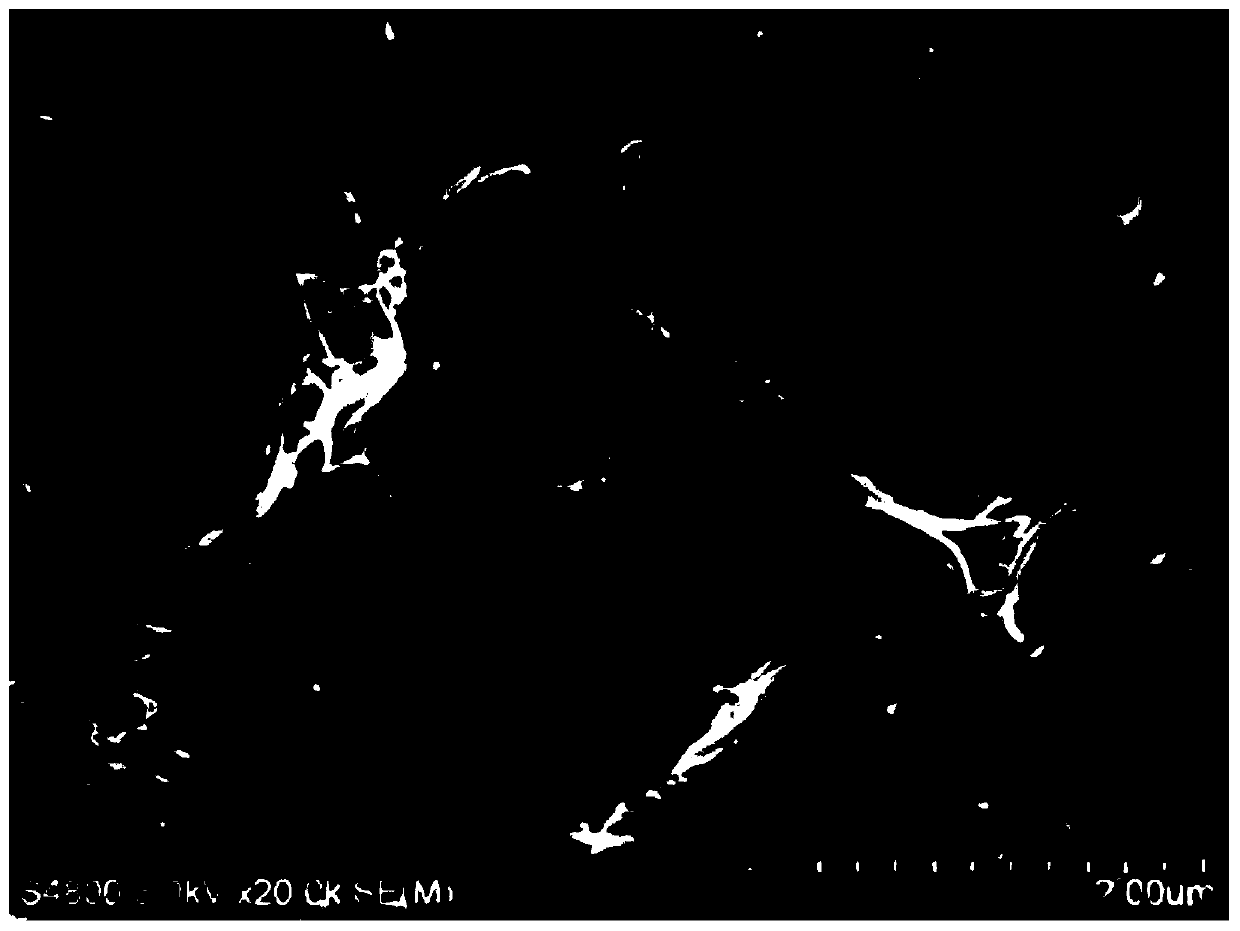

[0035] 1. Preparation of gel electrode: first mix 40mg of carbon nanotubes with ionic liquid, grind them on a mortar, remove them with a hanging spoon after 20 minutes, put them into a 5ml glass bottle, and then continue to add 2.5ml of the used solvent 4-methyl-2-pentanone, dissolved at 80°C in PVDF-HFP high-temperature solution, and finally mixed with 10mg of acetylene black, and continued to stir at 80°C for 4 hours to form a high-temperature solution Viscous solution, the viscous solution will form a colloidal state after cooling down, which is a weakly physically cross-linked gel. The resulting gel is macroscopically photographed and the resulting gel is lyophilized and photographed for scanning electron microscopy, as in figure 1 , figure 2 shown.

[0036] 2. Take the monomer N,N-dimethylacrylamide (DMAA) with a mass fraction of 5% to 20%, and the cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com