Method for preparing composite material by embedding MoS2 nanosheets in carbon substrate and application of composite material

A technology of nanocomposite materials and composite materials, which is applied in the field of preparation of MoS2 nanosheets embedded in carbon substrate composite materials, can solve the problems of poor cycle stability, large volume expansion, poor conductivity, etc., and achieves simple methods, short synthesis time, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 molybdenum metal reaction chamber to MoS 2 / C nanocomposite preparation

[0050] This example shows that molybdenum metal is the reaction chamber, and the protective atmosphere is argon on MoS 2 / C nanocomposite preparation, the specific preparation process is as follows:

[0051] The solution of ammonium tetrathiomolybdate and dimethylformamide with a mass ratio of 2:3 was used as the reaction precursor, the heating rate was 10°C / min, the holding time was 1h, and the reaction temperature was 500°C to prepare MoS 2 / C nanocomposites.

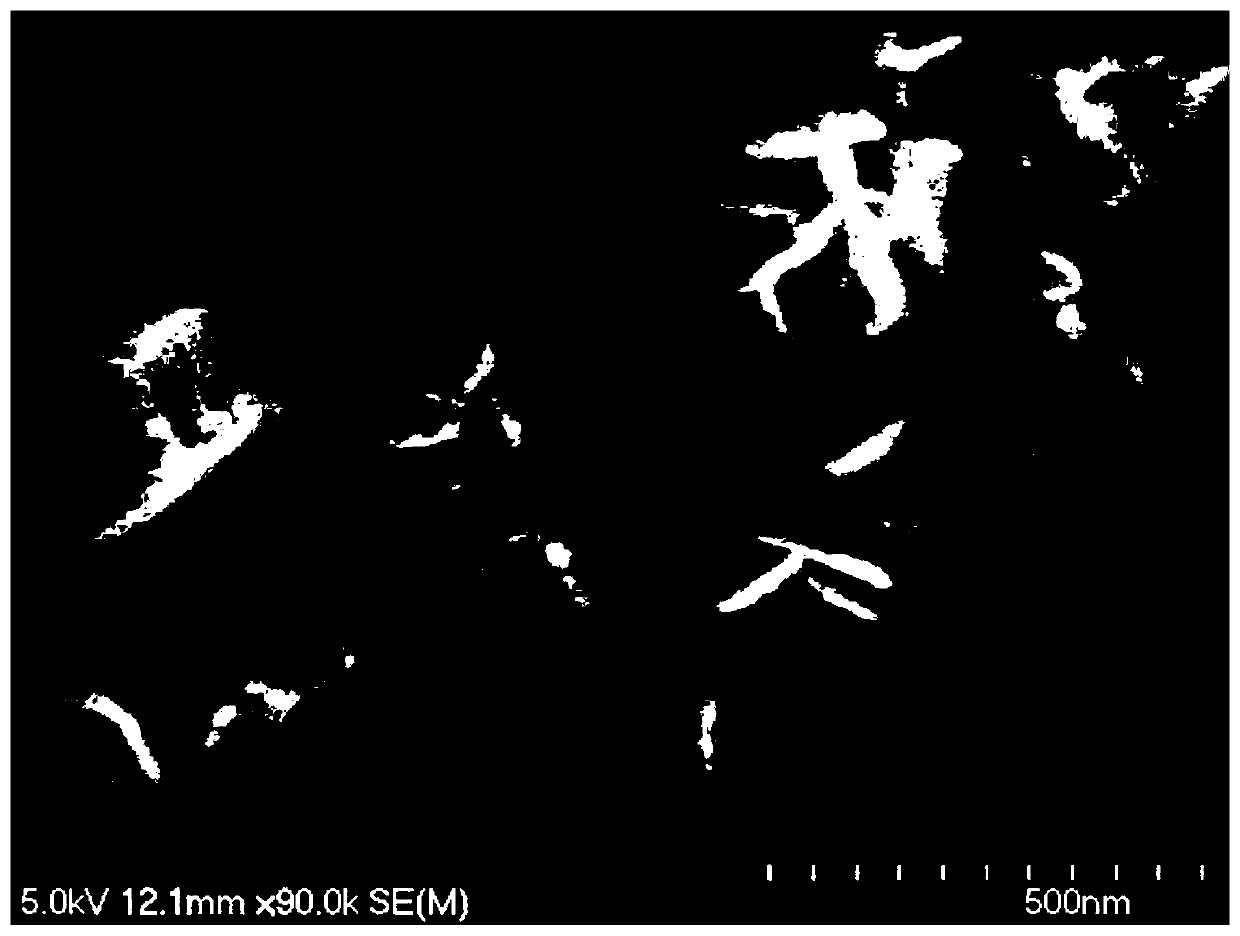

[0052] figure 1 is MoS obtained in a molybdenum metal reaction chamber 2 SEM images of / C nanocomposites.

[0053] from figure 1 It can be seen that MoS 2 / C nanocomposites have been formed.

Embodiment 2

[0054] Example 2 MoS at 700°C 2 / C nanocomposite preparation

[0055] This example demonstrates the effect of reaction temperature 700°C on MoS 2 The preparation of / C nanocomposite material, reaction cavity and protective atmosphere are the same as embodiment 1, and concrete preparation process is as follows:

[0056] A solution with a mass ratio of ammonium tetrathiomolybdate and dimethylformamide of 1:2 was used as the reaction precursor, the heating rate was 10°C / min, and the holding time was 0.5h.

[0057] figure 2 is MoS obtained at 700°C 2 / C nanocomposite SEM photographs.

[0058] from figure 2 It can be seen that MoS 2 / C nanocomposites have been formed.

Embodiment 3 4

[0059] Example 3 The mass ratio of ammonium tetrathiomolybdate to dimethylformamide is 2:3 to prepare MoS 2 / C Nanocomposite

[0060] This example demonstrates that a solution of ammonium tetrathiomolybdate and dimethylformamide with a mass ratio of 2:3 is used as a reaction precursor to prepare MoS 2 / C nanocomposite material, reaction chamber and protective atmosphere are the same as in Example 1, and the specific preparation process is as follows:

[0061] 1.5g of the reaction precursor, under the conditions of 600°C and a heating rate of 10°C / min, the holding time is 0.5h.

[0062] image 3 MoS obtained from a solution of ammonium tetrathiomolybdate and dimethylformamide with a mass ratio of 2:3 as a reaction precursor 2 / C nanocomposite SEM photographs.

[0063] from image 3 It can be seen that MoS 2 / C nanocomposites have been formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com