A kind of device and method for separating methyl linolenic acid based on ionic liquid supported liquid membrane

A technology of methyl linolenate and ionic liquid, which is applied in the fields of semipermeable membrane separation, chemical instruments and methods, and preparation of carboxylate, can solve the problems of high cost, complicated operation, and low purity, and achieve strong stability and easy operation. The effect of simplicity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

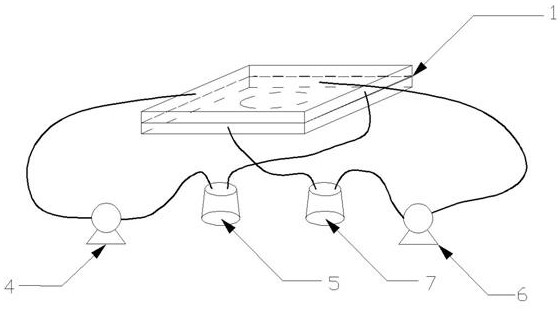

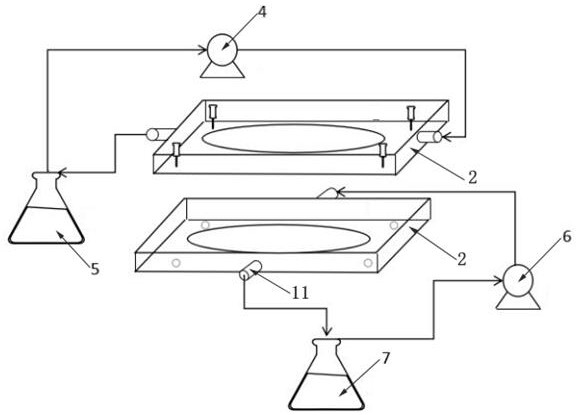

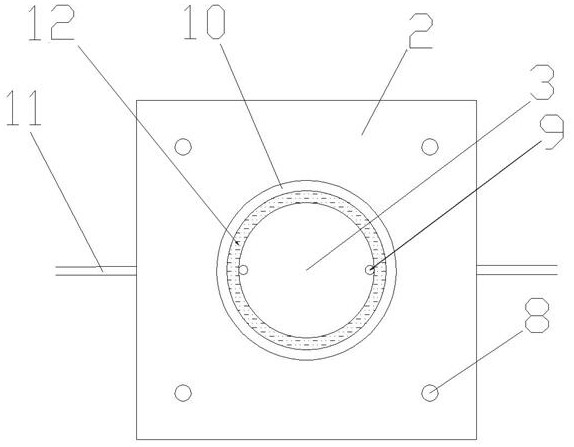

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 (50mg / mL raw material concentration-40.1mL / min flow rate-[C 4 mim] BF 4 )

[0039] 1) Preparation of tallow catalpa oil methyl ester raw material

[0040] The methyl esterification of tallow tree oil adopts a known method: weigh 20g of methanol and 1g of KOH, mix and dissolve them, add them to 100g of tallow tree oil, stir and reflux at 60°C for 1 hour, let stand to separate layers, and take the upper oil layer for use. Wash with water until neutral, and remove water in vacuum to obtain the raw material of tallow oil methyl ester. Through mass spectrometer and gas chromatograph, the content of methyl linolenic acid in tallow catalpa oil methyl ester raw material is 21.54%.

[0041] 2) Preparation of ionic liquid membrane solution

[0042] Take 0.5 mL of 1-butyl-3-methyl-imidazolium tetrafluoroborate [C 4 mim] BF 4 and 0.25g AgBF 4 Mix well in the centrifuge tube; add 0.6mL of 1-hexene as a pretreatment agent into the centrifuge tube, vortex shaker fo...

Embodiment 2

[0050] Embodiment 2 (100mg / mL raw material concentration-40.1mL / min flow velocity-[C 4 mim][BF 4 ])

[0051] On the basis of Example 1, the concentration of the petroleum ether solution of tallow oil methyl ester was changed to 100 mg / mL, and the remaining conditions were the same as in Example 1.

[0052] Take 1mL stripping solvent from the stripping phase tank 5 per hour for gas chromatography analysis; carry out 6 hours sampling analysis results: the mass content of methyl linolenate is 65.51%, the concentration is 0.3821mg / mL, the permeation flux of methyl linolenate 0.0728mg / (cm 2 h).

Embodiment 3

[0053] Embodiment 3 (50mg / mL raw material concentration-40.1mL / min flow rate-[C 8 mim][BF 4 ])

[0054] Change the kind of ionic liquid on the basis of embodiment 1 to be 1-octyl-3-methyl-imidazole tetrafluoroborate [C 8 mim] BF 4 , the addition volume of ionic liquid is constant, all the other conditions are the same as embodiment 1.

[0055] Take 1mL stripping solvent from the stripping phase tank 5 per hour for gas chromatography analysis; carry out 6 hours sampling analysis results: the mass content of methyl linolenate is 56.30%, the concentration is 0.5301mg / mL, the permeation flux of methyl linolenate 0.0979mg / (cm 2 h).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com