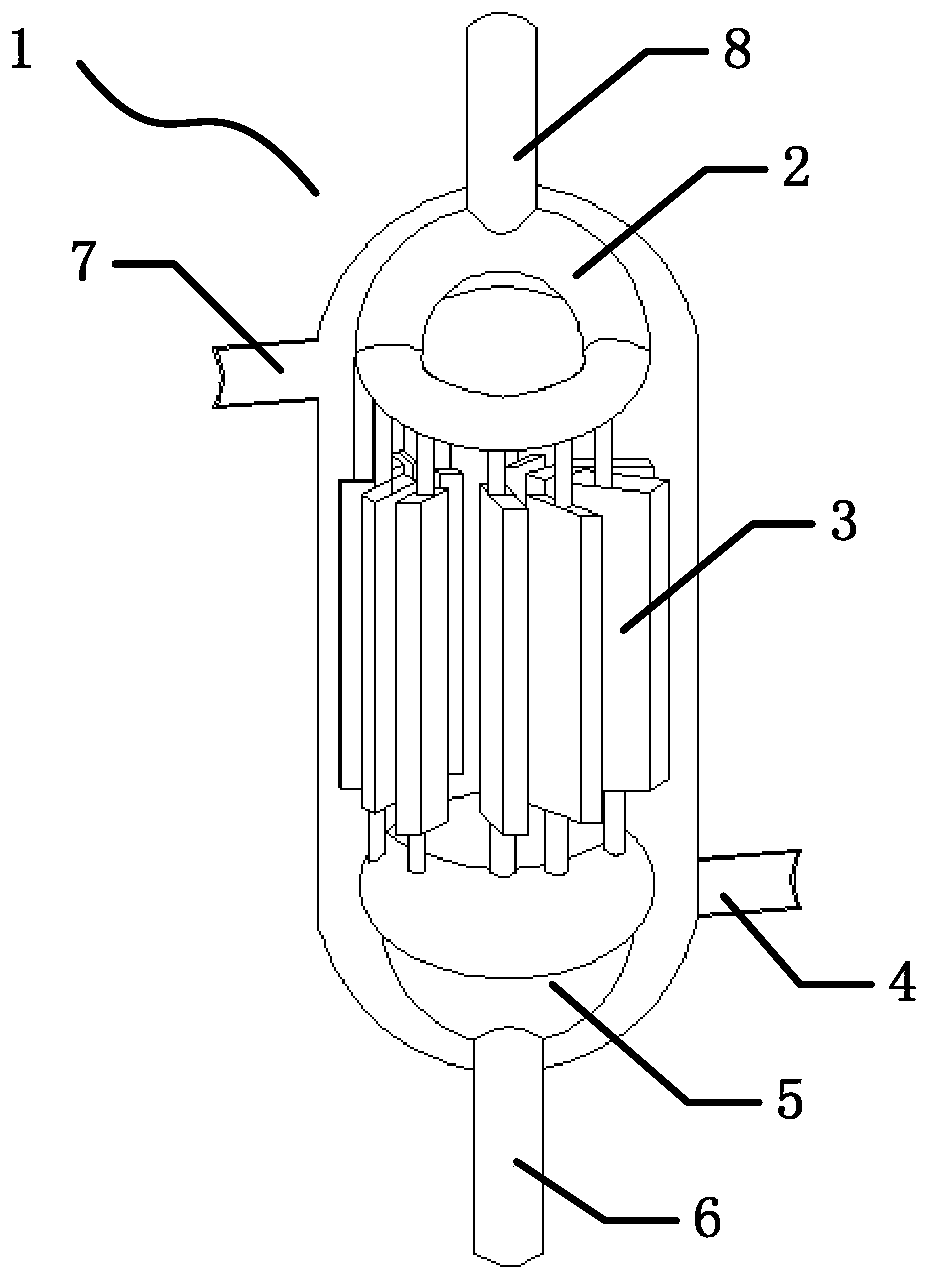

Reaction device

A reaction device and reaction technology, applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as narrow catalyst adaptability, limited processing capacity, and difficult reaction temperature. , to achieve the effect of good adaptability, various filling methods and wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

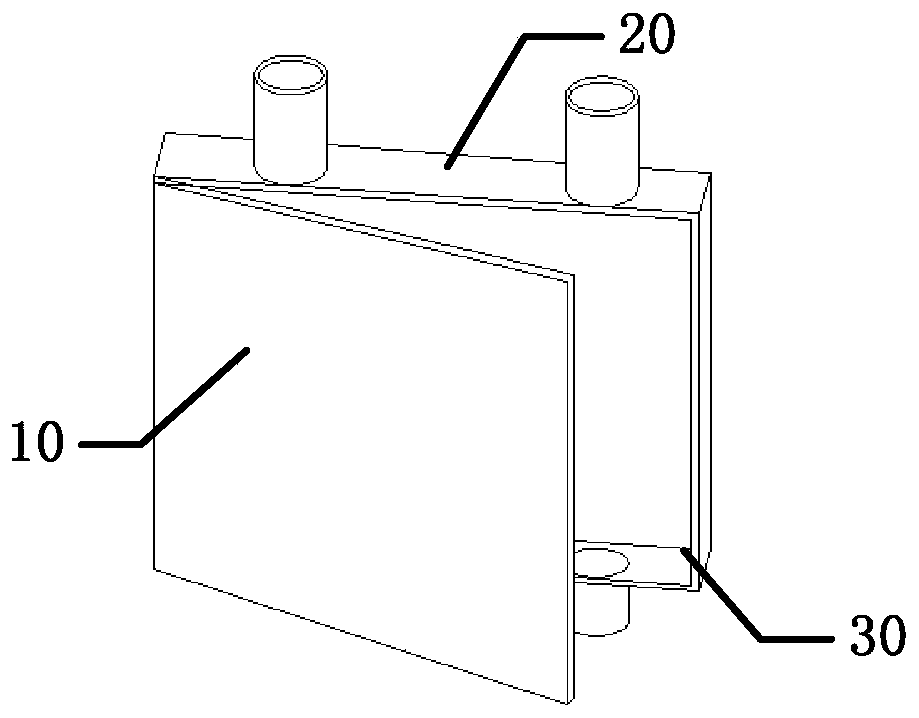

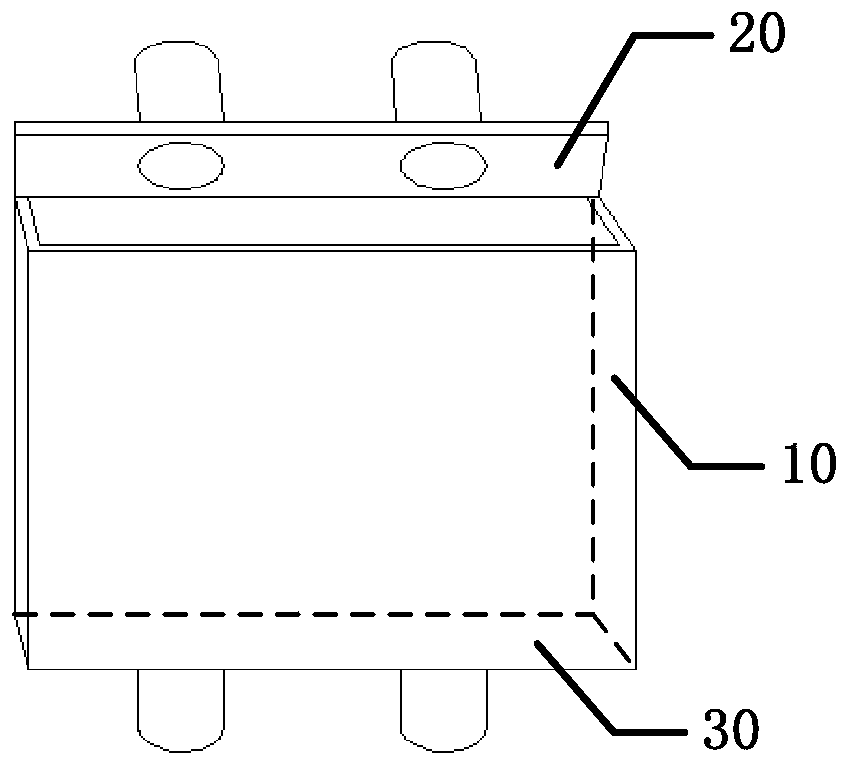

Method used

Image

Examples

Embodiment 1

[0082] The reaction device of the present invention is applied to the synthesis gas carbonylation reaction to produce dimethyl oxalate, wherein: the plate reactor is 8m high, 32mm thick, and 2.3m wide, and the plates are arranged radially in the same size plate reactor. The data of the reaction material inlet and the reaction product outlet are calculated as shown in Table 1.

[0083] Table 1

[0084]

[0085]

[0086] As can be seen from the results in Table 1, the reaction device of the present invention can better control the reaction temperature, so that the preparation of dimethyl oxalate by carbon monoxide oxidative coupling can be carried out under almost isothermal conditions.

[0087] In addition, the reaction device of the present invention can also be used for the reaction of carbon monoxide and methyl nitrite to synthesize dimethyl carbonate and the catalytic hydrogenation of dimethyl oxalate to prepare ethylene glycol.

Embodiment 2

[0089] The reaction device of the present invention is applied to the selective catalytic oxidation of hydrogen sulfide, wherein a granular hydrogen sulfide selective catalytic oxidation catalyst is filled in the plate reactor, and the catalyst has the advantages of high selectivity, water resistance, high sulfur recovery rate and the like. The height of the plate reactor is 5m, the thickness is 400mm, and the width is 670mm. The inlet flow rate of the reaction plate is 100mol / s. The plate layout adopts the radial arrangement of the same size plate reactor. The data of the reaction material inlet and the reaction product outlet are calculated as shown in Table 2.

[0090] Table 2

[0091]

[0092]

[0093] As can be seen from the results in Table 2, the reaction device of the present invention is used for the selective catalytic oxidation of hydrogen sulfide, and can preferably remove the heat released by the reaction, and the temperature of the reaction zone is controll...

Embodiment 3 and comparative example 1

[0095] Selective Catalytic Oxidation with Hydrogen Sulfide As an example, compare the traditional tube-and-tube reactor with the reaction device of the present invention. The device specifications and reaction data are calculated as shown in Table 3, and the heat exchange medium is 170°C.

[0096] table 3

[0097]

[0098] It can be seen from the results in Table 3 that under the same conditions, for the selective catalytic oxidation of hydrogen sulfide, the conversion rate of the reaction device with the plate reactor is significantly higher than that of the traditional shell and tube reactor. In Example 3, the number of plate reactors in the continuous heat exchange reaction device is only 3. Compared with Comparative Example 1, the internal structure of the reaction device is greatly simplified, which is convenient for installation, disassembly and maintenance, and at the same time can achieve Better responsiveness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com