A preparation method of special long-life lubricating grease for intelligent robot joints and bearings

An intelligent robot and grease technology, applied in the field of grease, can solve the problems of poor compatibility of plastic parts, poor lubricating performance, short service life, etc. Fill accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

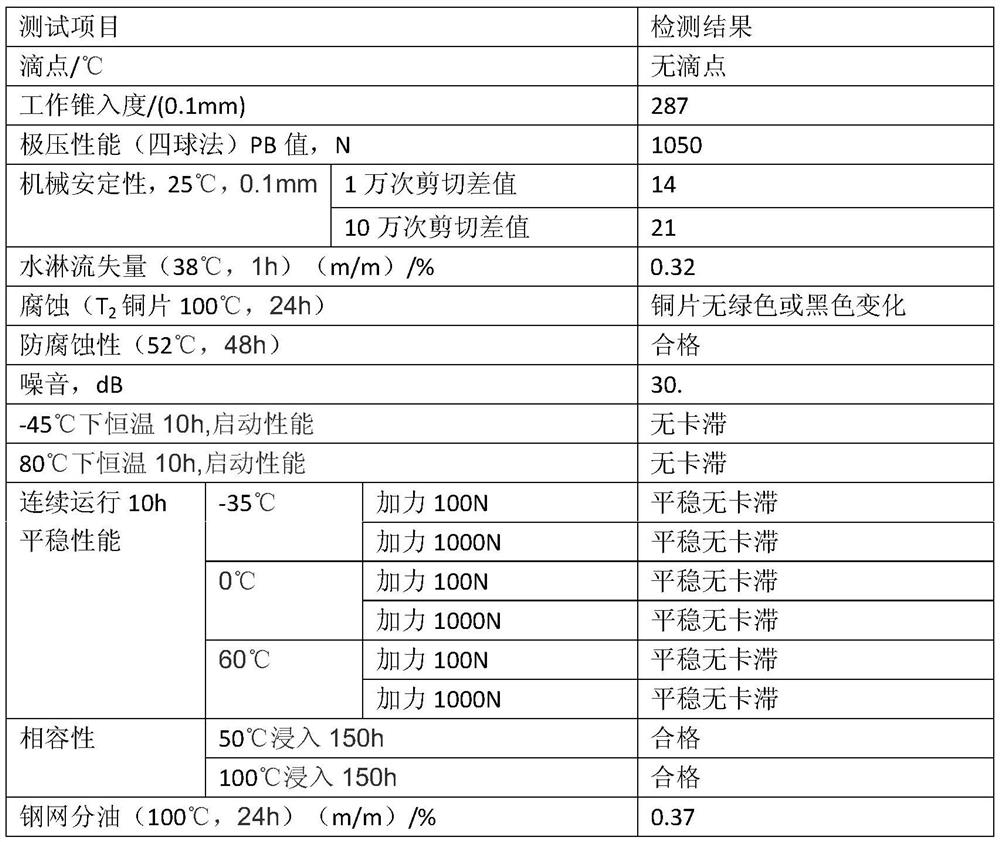

Embodiment 1

[0015] A1. Preparation of special blending oil: choose a viscosity of 5mmp at 100°C a .s naphthenic base oil 7Kg, viscosity at 100°C is 12.5mmp a .s naphthenic base oil 1Kg, mix these two base oils evenly. Then add 0.622Kg of OCP sol, 0.311Kg of PIB1300 tackifier, and 0.577Kg of OSP320 polyether and mix well between 50-70°C. This mixed oil is a special blended oil.

[0016] A2, produce No. 2 non-dropping point lithium base grease with the special blend oil of A1, get 7Kg from it for subsequent use.

[0017] A3. Use 7KgA2 non-dropping point lithium-based grease and 21Kg2# non-dropping point silicone grease to mix evenly.

[0018] A4. Add 0.206Kg of rust inhibitor N-oleoyl sarcosine stearylamine and 0.079Kg of benzotriazole derivative T551 into A3 and mix well.

[0019] A5, add 0.95Kg potassium borate colloidal solution to A4 and mix well.

[0020] A6, add 0.75Kg vulcanized cottonseed oil in A5 and mix well.

[0021] A7, add solid micropowder lubricant 1Kg zirconium phospha...

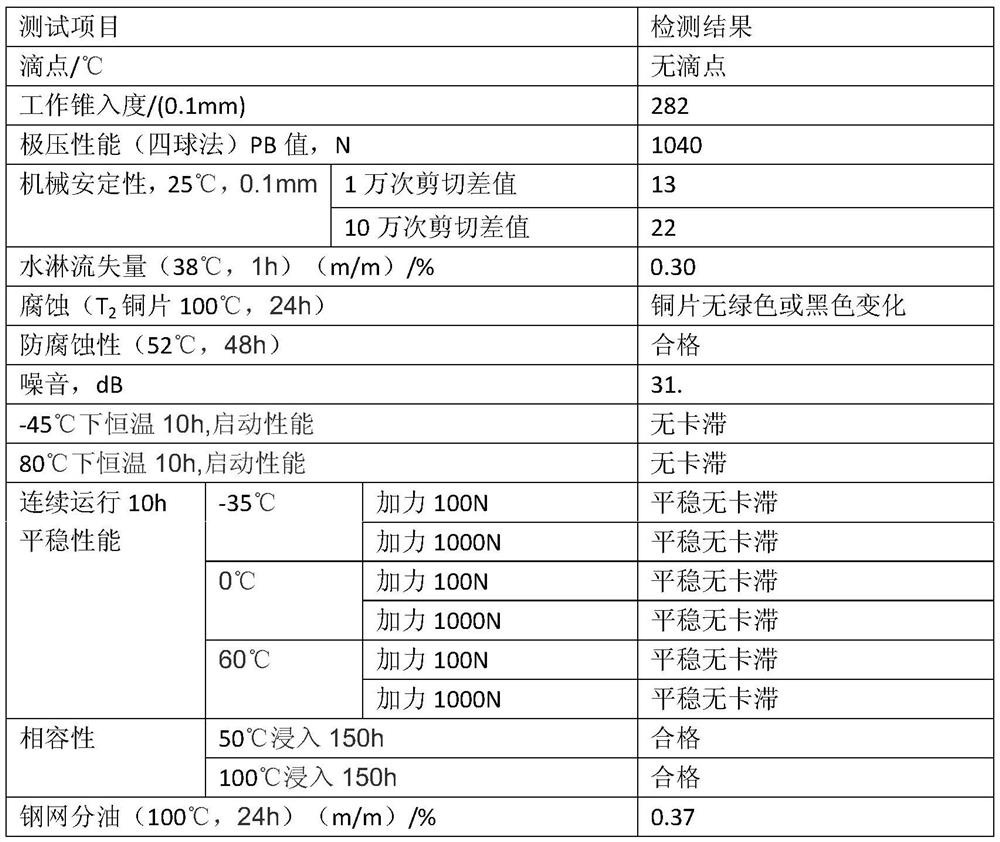

Embodiment 2

[0028] B1. Preparation of special blending oil: choose a viscosity of 4.2mmp at 100°C a .s naphthenic base oil 7.5Kg, viscosity 13mmp at 100°C a .s naphthenic base oil 1.3Kg, mix these two base oils evenly. Then add 0.651Kg of OCP0010 sol, 0.320Kg of PIB1300 tackifier, 0.652Kg of OSP320 polyether and mix evenly at 50-70°C. This mixed oil is a special blended oil.

[0029] B2, produce No. 2 lithium base grease without dropping point with the special blend oil of B1, get 8.5Kg therefrom for subsequent use.

[0030] B3. Use 8.5Kg B2 non-dropping point lithium-based grease and 29.5Kg2# non-dropping point silicone grease to mix evenly.

[0031] B4. Add rust inhibitor N-oleoyl sarcosine stearylamine 0.412Kg and 0.045Kg benzotriazole derivative T551 to B3 and mix well.

[0032] B5, add 1.1Kg potassium borate colloidal solution to B4 and mix well.

[0033] B6, add 0.8Kg vulcanized cottonseed oil in B5 and mix well.

[0034] B7, add solid micropowder lubricant 3.2Kg triphenyl thio...

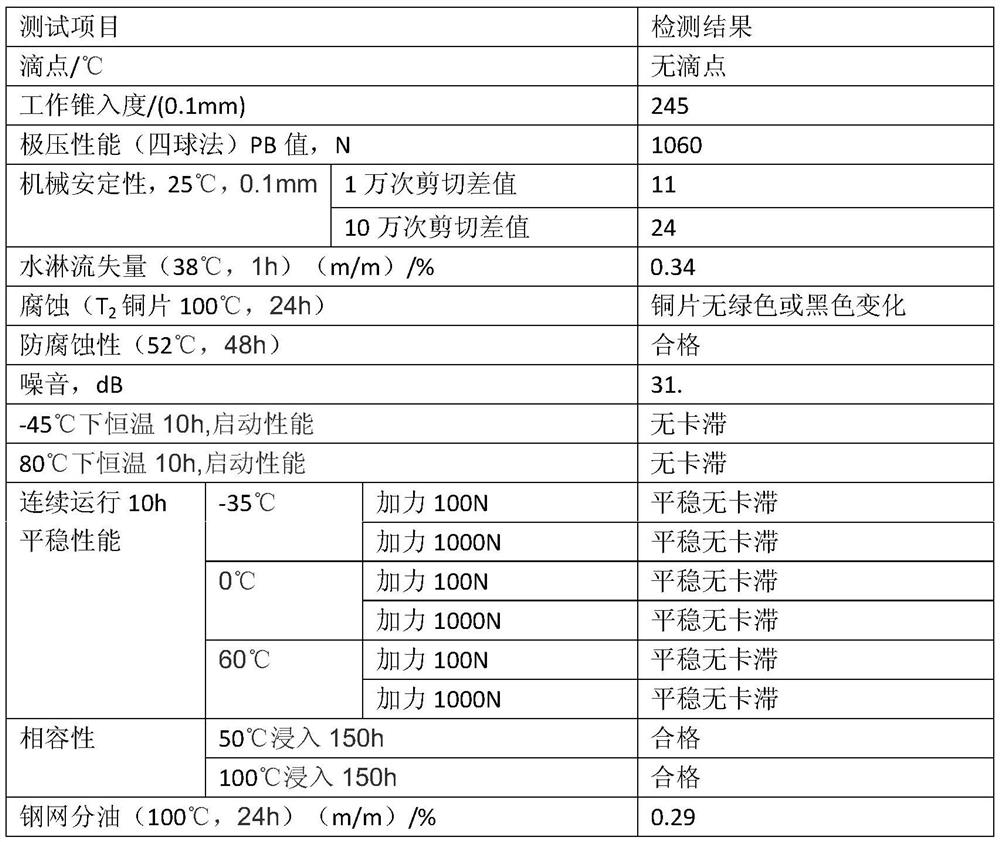

Embodiment 3

[0041] C1. Preparation of special blending oil: choose a viscosity of 5.3mmp at 100°C a .s naphthenic base oil 6.5Kg, viscosity at 100°C is 11mmp a .s naphthenic base oil 1Kg, mix these two base oils evenly. Then add 0.521Kg of OCP0010 sol, 0.298Kg of PIB1300 tackifier, 0.524Kg of OSP320 polyether and mix evenly at 50-70°C. This mixed oil is special blended oil.

[0042] C2, produce No. 3 lithium base grease without dropping point with the special blend oil of C1, get 6.5Kg therefrom for subsequent use.

[0043] C3. Use 6.5Kg C2 non-dropping point lithium-based grease and 24.7Kg3# non-dropping point silicone grease to mix evenly.

[0044]C4. Add rust inhibitor N-oleoyl sarcosine stearylamine 0.276Kg and 0.084Kg benzotriazole derivative T551 to C3 and mix well.

[0045] C5, add 0.8Kg potassium borate colloidal solution to C4 and mix well.

[0046] C6, add 0.7Kg vulcanized cottonseed oil to C5 and mix evenly.

[0047] C7, add solid micropowder lubricant 1.9.Kg antimony dibu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com