Method for preparing fuel ethanol from kitchen waste

A technology for kitchen waste and fuel ethanol, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of imperfect ethanol fermentation and distillation processes, inability to achieve sustainable development, and high moisture content of kitchen waste. problems, to achieve the effect of saving cooking process, high starch content and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

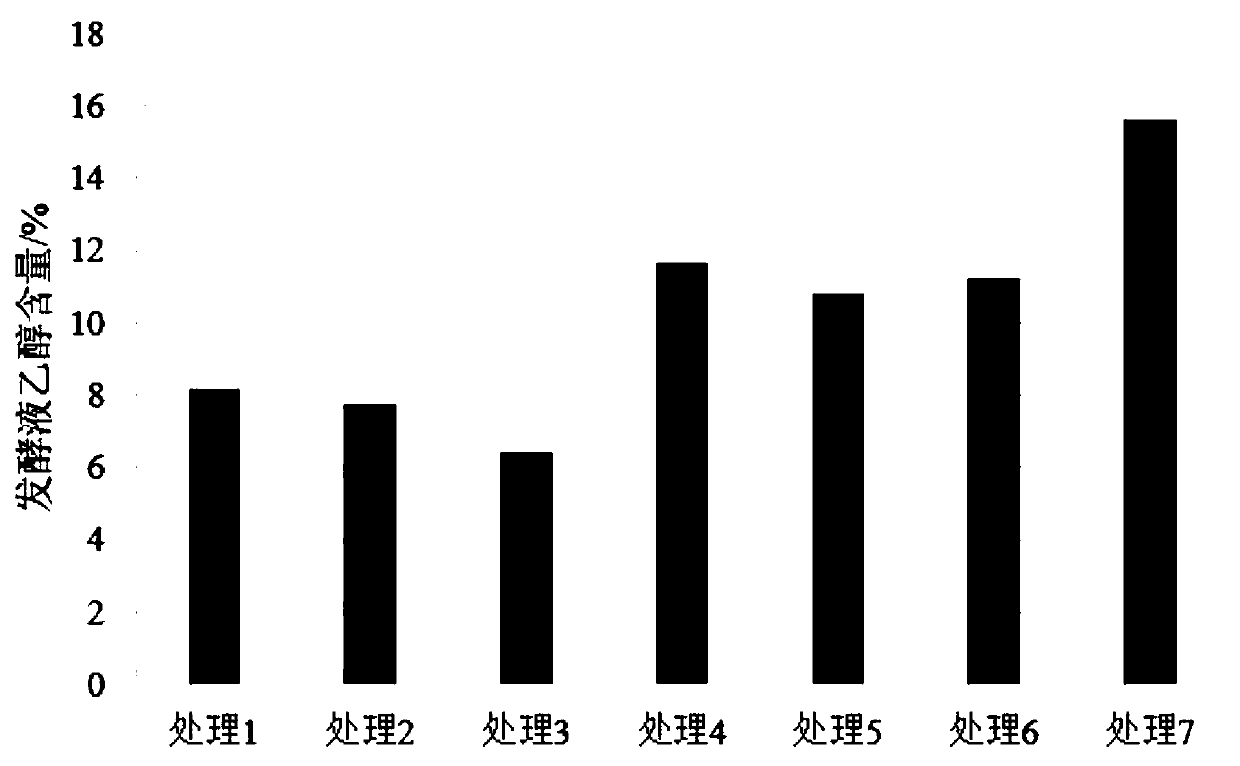

[0032] Experimental setting method: In this example, the yeast strains and inoculation amount used as mash fermentation are used as variables, and several treatment groups in the facility carry out a series of processing treatments on food waste to prepare ethanol, so as to explore the impact of the above variables on mash The effect of ethanol content in the fermented broth obtained by fermentation.

[0033] Main strains: Saccharomyces cerevisiae Rasse II, Saccharomyces cerevisiae K, Saccharomyces cerevisiae Hakken No.1.

[0034] Main instruments: WHL-65B vertical drying oven: Beijing Zhongxing Weiye Instrument Co., Ltd.; 0.40mm hole sieve: Shaoxing Shangyu Daoxu Yanguang Instrument Equipment Factory; GC-7890 gas chromatograph: Shanghai Chuanhao Instrument Co., Ltd.; BS- 2F shaking incubator: Jintan District Shuibei Science Popularization Experimental Instrument Factory; DH-360 electric heating constant temperature incubator: Beijing Zhongxing Weiye Instrument Co., Ltd.

[0...

Embodiment 2

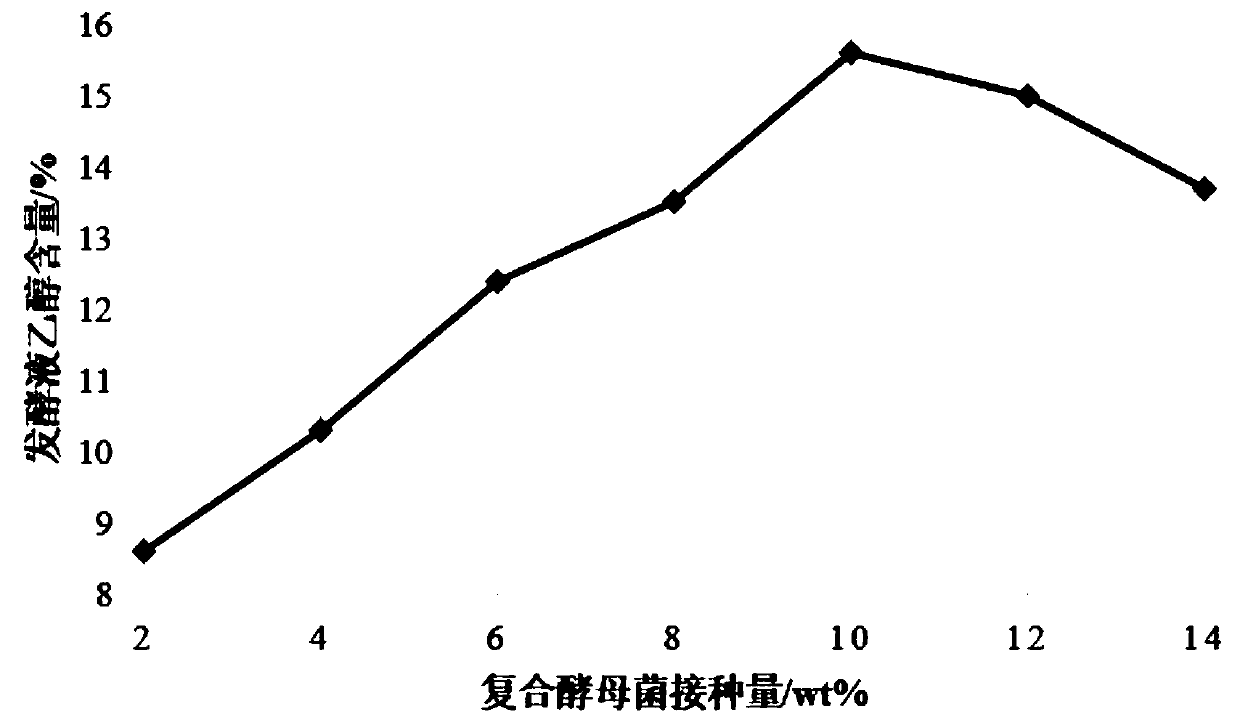

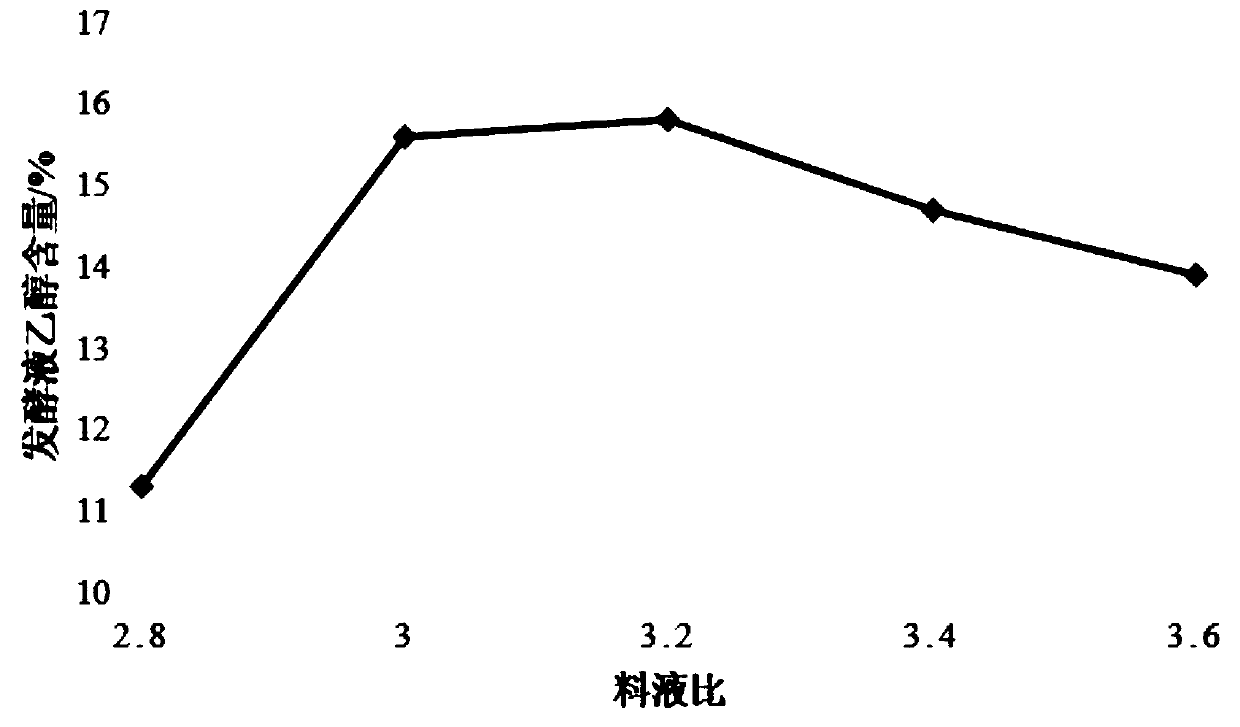

[0060] Experiment setup method: In this example, the material-to-water ratio, slurry pH value, and saccharification temperature of starchy waste in the past were used as variables, and several treatment groups were used to process food waste to prepare ethanol in order to explore the above-mentioned processing. Effect of process parameter variables on ethanol content of fermentation broth obtained from mash fermentation.

[0061] Main instruments: WHL-65B vertical drying oven: Beijing Zhongxing Weiye Instrument Co., Ltd.; 0.40mm hole sieve: Shaoxing Shangyu Daoxu Yanguang Instrument Equipment Factory; GC-7890 gas chromatograph: Shanghai Chuanhao Instrument Co., Ltd.; BS- 2F shaking incubator: Jintan District Shuibei Science Popularization Experimental Instrument Factory; DH-360 electric heating constant temperature incubator: Beijing Zhongxing Weiye Instrument Co., Ltd.

[0062] Test index: ethanol content of the fermented liquid obtained after mash fermentation.

[0063] 1. ...

Embodiment 3

[0094] 1. Experiment setup method

[0095] In this example, the composition of the entrainer is used as a variable, and several treatment groups are installed to prepare and extract ethanol from food waste in a series of treatments, so as to explore the influence of the composition of the entrainer on the purity of ethanol. The composition of the entrainer corresponding to each treatment group in this embodiment is shown in Table 2. Except for the variables listed in Table 2, all corresponding technical points of each treatment group are strictly consistent. The ratios listed in Table 2 are the molar ratios of the components constituting the entrainer. In this embodiment, a control group is set, and no entrainer is used in the distillation process of the control group.

[0096] The concrete composition of the entrainer that each processing group adopts in the present embodiment of table 2

[0097]

[0098] 2. Main instruments

[0099]WHL-65B vertical drying oven: Beijing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com