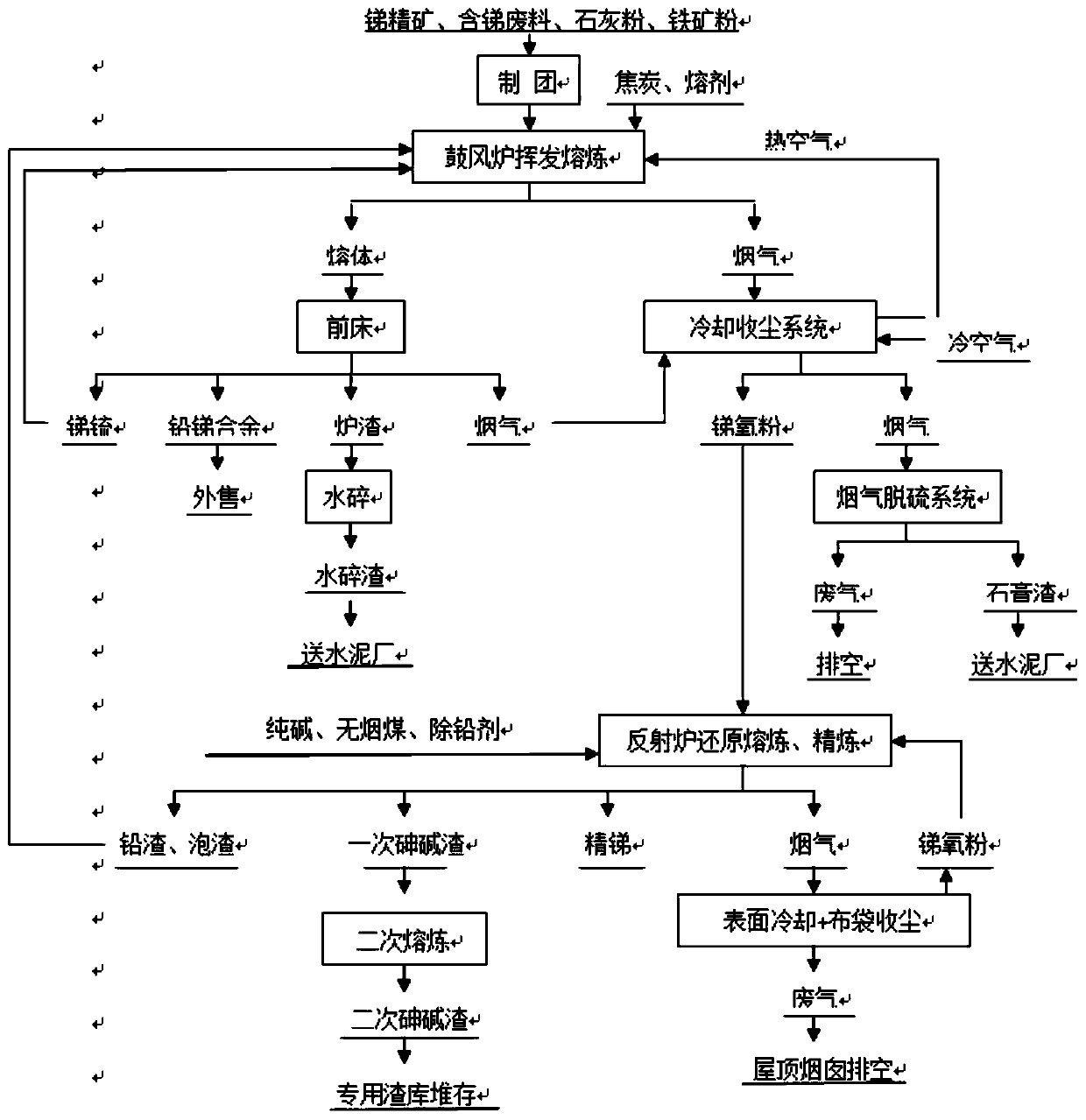

Antimony smelting arsenic-alkali residue and smelting off-gas comprehensive treatment method

A technology for comprehensive treatment of smelting flue gas, which is applied in the comprehensive treatment of antimony smelting arsenic-alkali slag and smelting flue gas. The leaching toxicity is unqualified, there are hidden dangers of dissolution, pipelines are easily blocked, etc., to achieve the effect of improving the level of green and clean circulation production, the filtration process is stable and smooth, and the production continuity is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

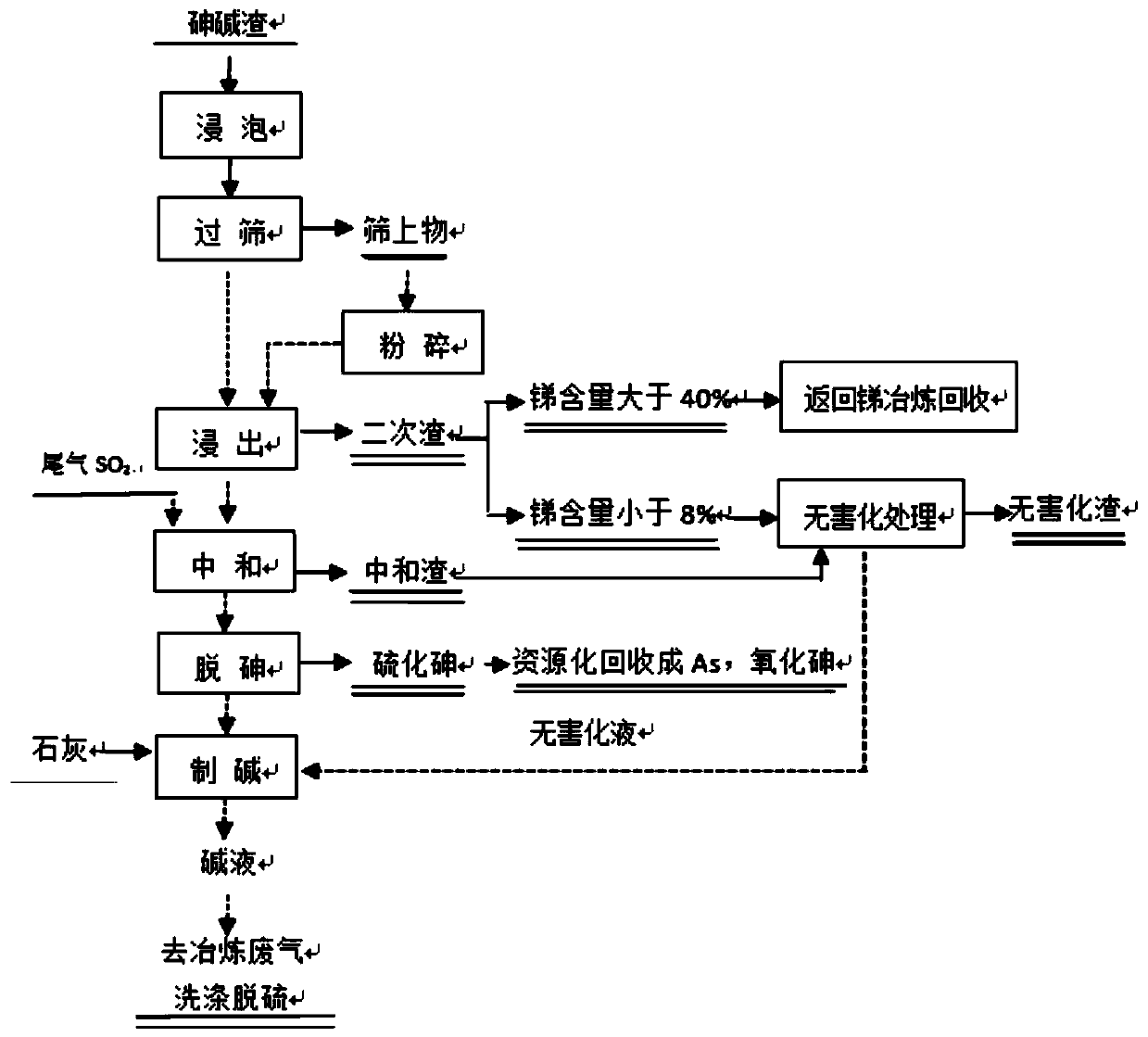

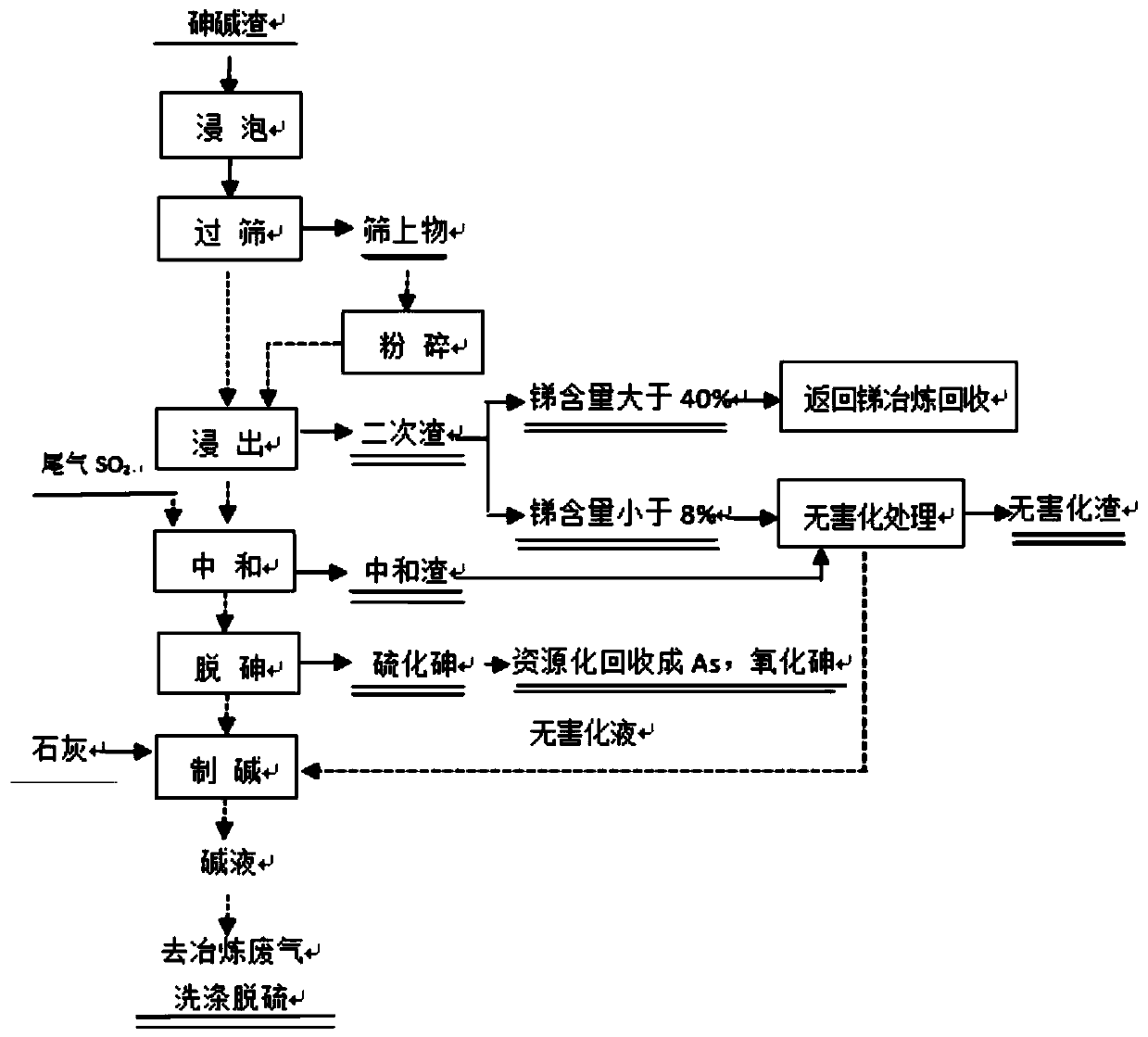

Method used

Image

Examples

Embodiment 1

[0051] A method for wet processing antimony smelting arsenic-alkali slag, the method comprises the following steps:

[0052] (1) Soaking, sieving and crushing process: add 800ml of secondary leachate and 3700ml of tap water to 1500g of secondary arsenic-alkali slag, the liquid-solid ratio of secondary arsenic-alkali slag to leaching solution is 4:1, immerse at room temperature for 30 hours, stir After the pulping is complete, sieve to separate the slag and water, soak the slurry (including the slurry after the crushed oversize and the slurry after sieving) and enter the leaching process;

[0053] Wherein, the composition of secondary arsenic-alkali slag comprises (by mass percentage): Na 2 CO 3 50.83%, NaOH 0.86%, As 12.61%, Sb 1.27%, Al 2.32%, Si 3.26%;

[0054] (2) Leaching process: the arsenic-alkali slag is leached by two-stage countercurrent water leaching:

[0055] i. Heat preservation and leaching of the above soaking slurry, the conditions of heat preservation leac...

Embodiment 2

[0065] A method for wet processing antimony smelting arsenic-alkali slag, the method comprises the following steps:

[0066] (1) Soaking, sieving and crushing process: Add 5000ml of tap water to 1000g of primary arsenic-alkali slag, the liquid-solid ratio of primary arsenic-alkali slag and leachate is 8:1, immerse at room temperature for 48 hours, stir and slurry, after the slurries are complete, Sieve to separate slag and water, soak the slurry (including the slurry after the crushed oversize and the slurry after sieving) and enter the leaching process;

[0067] Wherein, the composition of primary arsenic-alkali slag comprises (by mass percentage): Na 2 CO 3 13.10%, NaOH 28.71%, As 11.64%, Sb 57.03%, Al 0.27%, Si 0.27%.

[0068] (2) Leaching process: the arsenic-alkali slag is leached by two-stage countercurrent water leaching:

[0069] i. Heat preservation and leaching the above soaking slurry. The conditions of heat preservation leaching are: heat preservation and leach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com