Super-hydrophobic thin film with photothermal effect and preparation method thereof

A photothermal effect, super-hydrophobic technology, used in ion implantation plating, coating, metal material coating process, etc., to delay or prevent icing, broad application prospects, and excellent anti-icing/de-icing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Grind the steel sheet with sandpaper, then ultrasonically clean it with acetone, alcohol, and deionized water in sequence and dry it;

[0022] 2. Fix the cleaned substrate on the sample stage of the electron beam evaporation coating machine, and pump the chamber of the electron beam evaporation coating machine to 10 -5 High vacuum below Pa;

[0023] 3. Adjust the incident angle of the electron beam to 89°, and make the sample stage static, and deposit a 200nm titanium nitride oblique rod array on the substrate;

[0024] 4. Convert the evaporation material to polytetrafluoroethylene, adjust the incident angle of the electron beam to 82°, and rotate the sample stage at a speed of 2 rpm, and deposit 100 nm of polytetrafluoroethylene on the top of the titanium nitride inclined rod array.

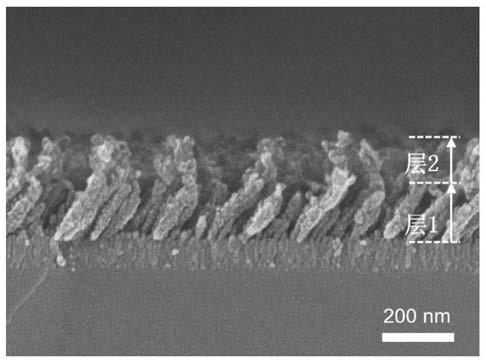

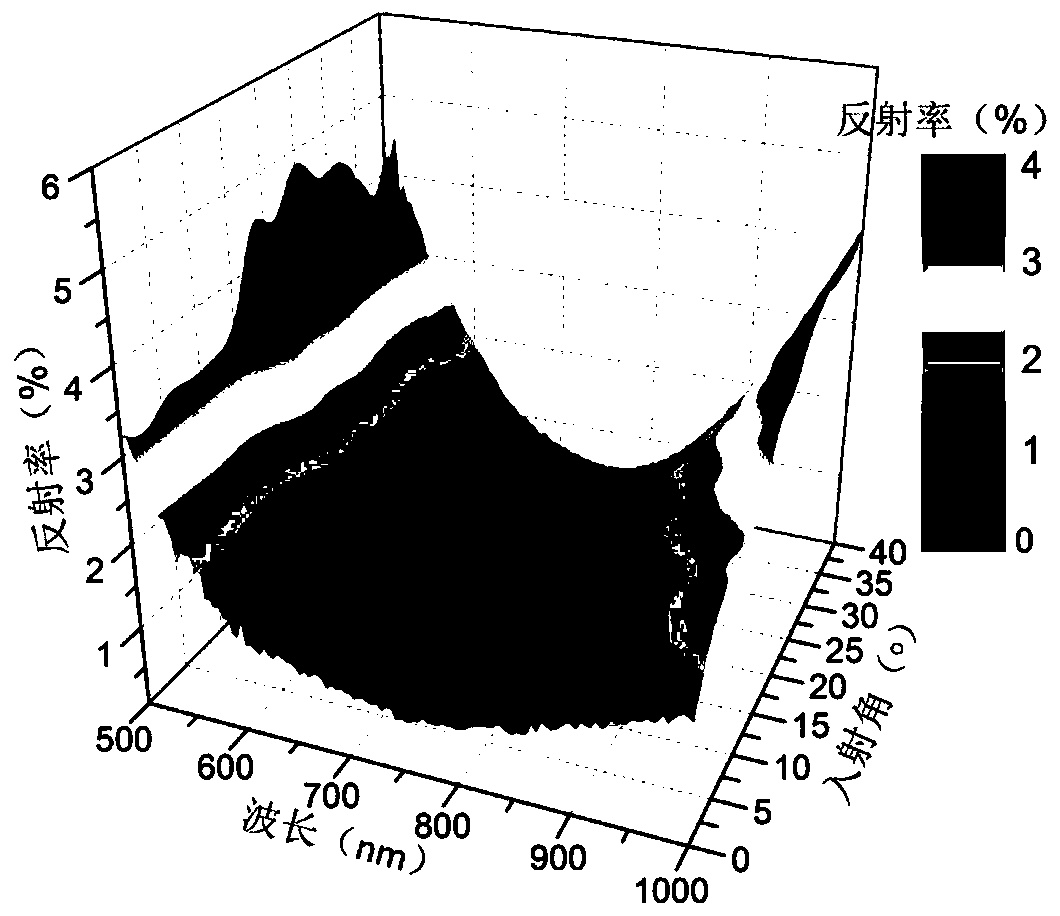

[0025] Figure 1a It is a scanning electron micrograph of the titanium nitride-polytetrafluoroethylene composite film prepared in Example 1; Figure 1b It is the reflectance curve of...

Embodiment 2

[0027] 1. Polish the aluminum sheet with sandpaper, then ultrasonically clean it with acetone, alcohol, and deionized water in sequence and dry it;

[0028] 2. Fix the cleaned substrate on the sample stage of the electron beam evaporation coating machine, and pump the chamber of the electron beam evaporation coating machine to 10 -5 High vacuum below Pa;

[0029] 3. Adjust the incident angle of the electron beam to be 85°, and make the sample stage rotate at a speed of 4rpm, and deposit a 1000nm silver straight rod array on the substrate;

[0030] 4. Convert the evaporation material to polystyrene, adjust the incident angle of the electron beam to 85°, and rotate the sample stage at a speed of 5 rpm, and deposit 500nm polystyrene on the top of the silver straight rod array.

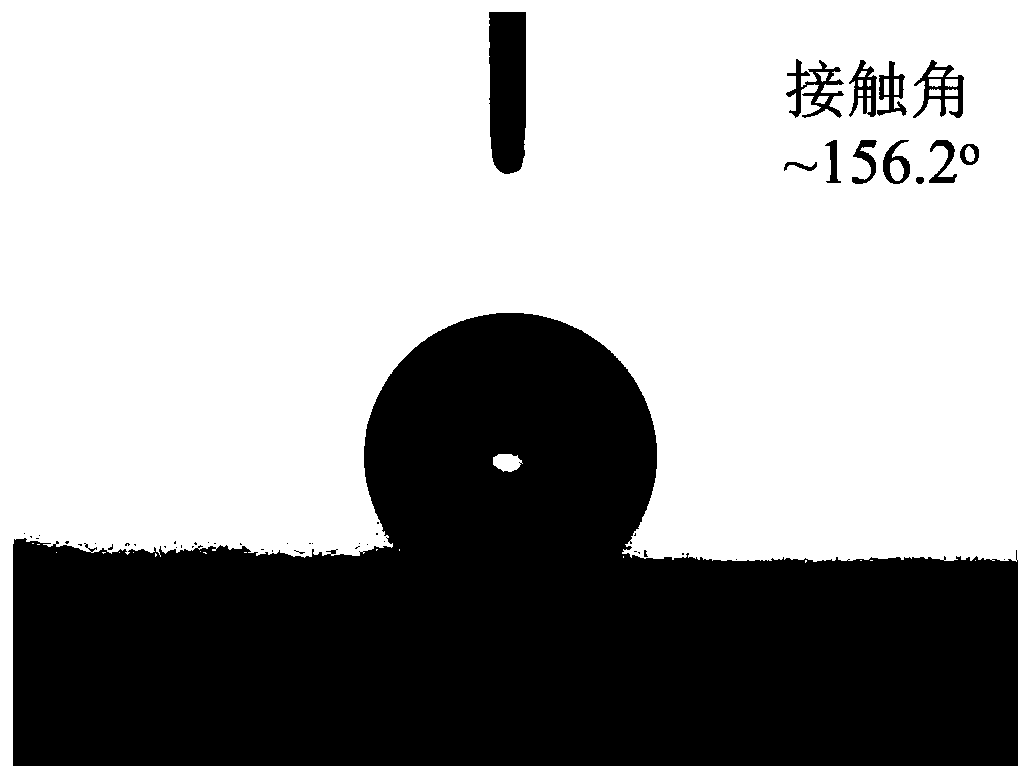

[0031] Fig. 2 is the contact angle of water on the silver-polystyrene composite film prepared in embodiment 2 and the photo of sliding angle. Due to the low surface energy of polystyrene and the large p...

Embodiment 3

[0033] 1. Polish the magnesium alloy sheet with sandpaper, then ultrasonically clean it with acetone, alcohol, and deionized water in sequence, and dry it;

[0034] 2. Fix the cleaned substrate on the sample stage of the electron beam evaporation coating machine, and pump the chamber of the electron beam evaporation coating machine to 10 -5 High vacuum below Pa;

[0035] 3. Adjust the incident angle of the electron beam to 82°, and rotate the sample stage at a speed of 10rpm, and deposit a 2000nm straight copper rod array on the substrate;

[0036] 4. Convert the evaporation material to polyethylene terephthalate PET, adjust the incident angle of the electron beam to 88°, and make the sample stage static, and deposit 1000nm PET on the top of the straight copper rod array.

[0037] image 3 For using the copper-polyethylene terephthalate PET composite film prepared in Example 3 under laser irradiation, the photo of the surface ice layer melting gradually. Because the nanostr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com