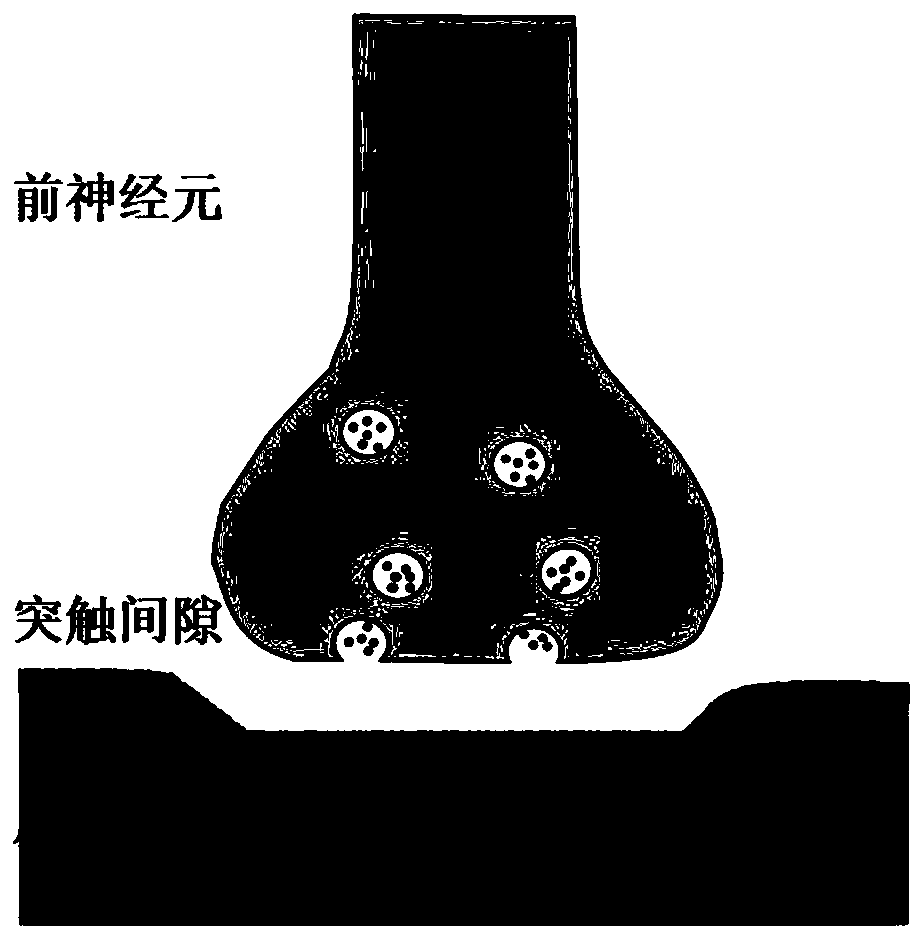

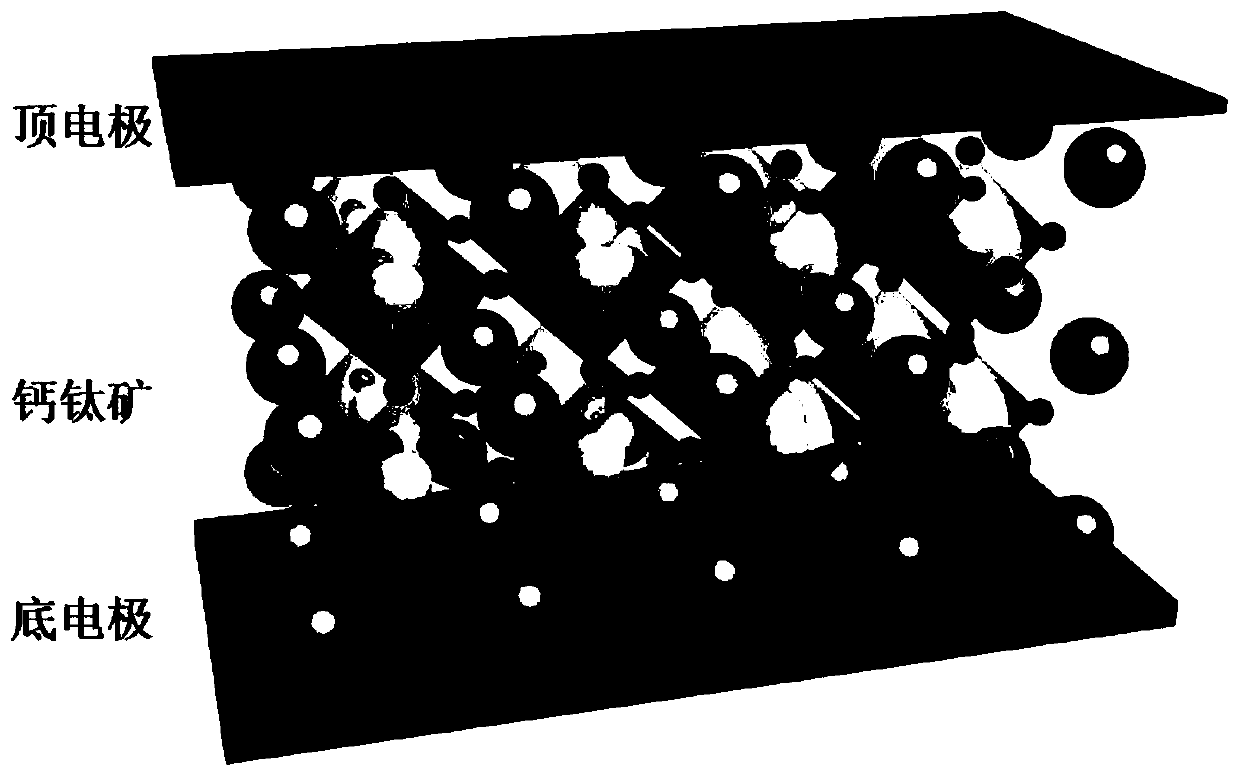

Preparation method of electronic device with artificial synapsis at two ends based on organic/inorganic hybrid perovskite

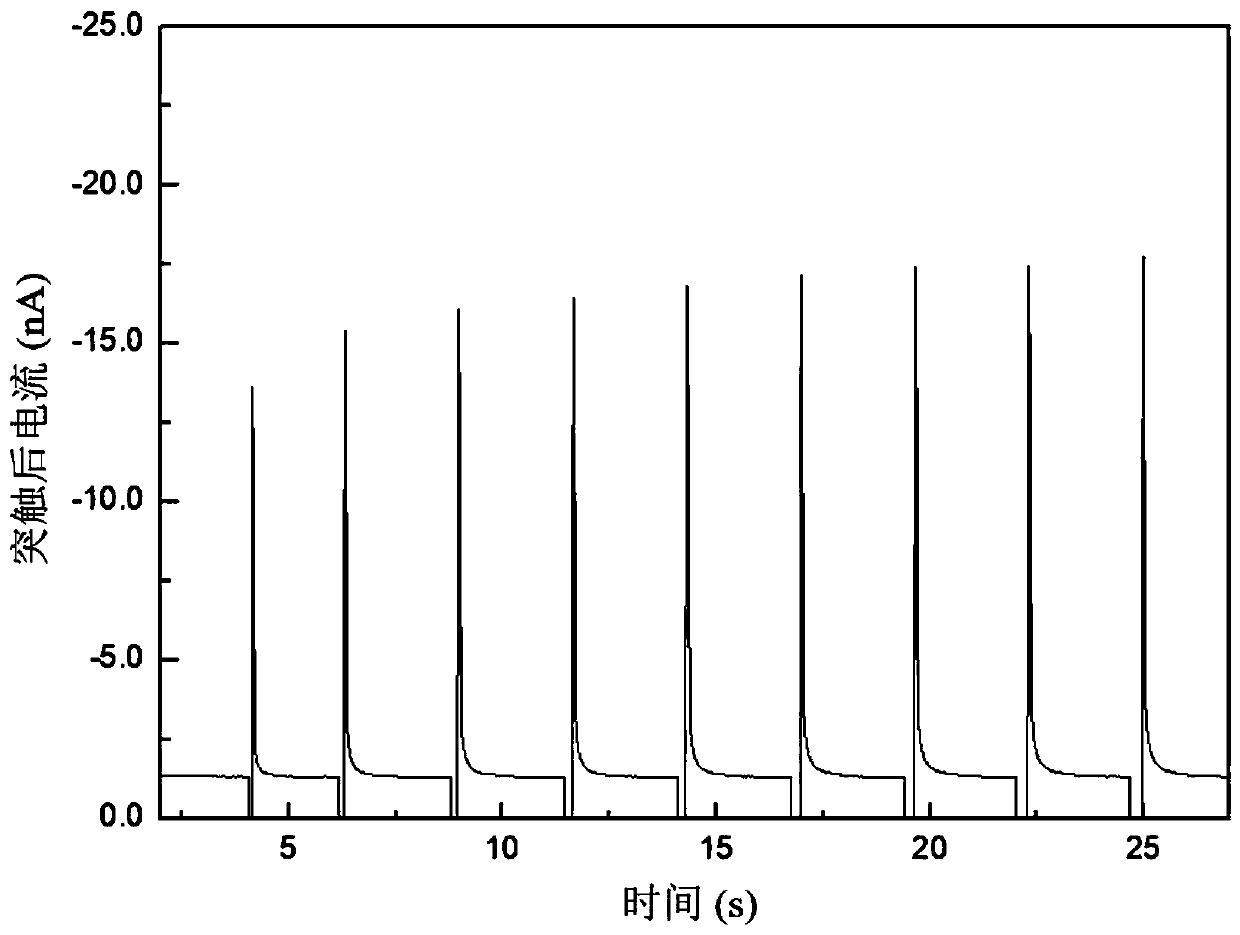

An electronic device, perovskite technology, applied in the field of artificial synapse electronic devices at both ends, can solve the problem of low sensitivity of artificial synapse, achieve high sensitivity, simplify the process flow, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) 1.5×1.5cm 2 The highly doped silicon substrate was placed in acetone solution for ultrasonic cleaning for 15min, then placed in isopropanol (IPA) solution for ultrasonic cleaning for 15min, then IPA was heated to boiling, and the surface of the substrate was fumigated with IPA hot steam, then use N 2 The gun blows the surface dry.

[0026] (2) lead bromide (PbBr) with a molar ratio of 1:1 2 ) and methyl amine chloride (MACl) were mixed and dissolved in a 4:1 volume ratio of dimethylformamide (DMF): dimethyl sulfoxide (DMSO) mixed solvent, and then the mixture was placed in a magnetic stirrer Stir until it is clear and transparent, and configure it into MAPbClBr with a mass fraction of 20%. 2 Perovskite solution.

[0027] (3) The obtained silicon substrate was placed in a UV-ozone cleaning machine for 20 min, and 50 μL of perovskite solution was taken on the obtained silicon substrate with a pipette, firstly at 1000 r·min -1 Spin coating at the speed of 10s, fol...

Embodiment 2

[0031] (1) 1.5×1.5cm 2 The highly doped silicon substrate was placed in acetone solution for ultrasonic cleaning for 15min, then placed in isopropanol (IPA) solution for ultrasonic cleaning for 15min, then IPA was heated to boiling, and the surface of the substrate was fumigated with IPA hot steam, then use N 2 The gun blows the surface dry.

[0032] (2) lead bromide (PbBr) with a molar ratio of 1.1:1 2 ) and methylamine bromide (MABr) and dissolved in a 5:2 volume ratio of dimethylformamide (DMF): dimethyl sulfoxide (DMSO) mixed solvent, and then the mixture was placed in a magnetic stirrer Stir until it is clear and transparent, and configure it into MAPbBr with a mass fraction of 20%. 3 Perovskite solution.

[0033] (3) The obtained silicon substrate was placed in an ultraviolet-ozone cleaning machine for 20 min, and 50 μL of the perovskite solution was taken on the obtained silicon substrate with a pipette, and the temperature was 800 r·min at first. -1Spin coating at...

Embodiment 3

[0037] (1) 1.5×1.5cm 2 The highly doped silicon substrate was placed in acetone solution for ultrasonic cleaning for 15min, then placed in isopropanol (IPA) solution for ultrasonic cleaning for 15min, then IPA was heated to boiling, and the surface of the substrate was fumigated with IPA hot steam, then use N 2 The gun blows the surface dry.

[0038] (2) lead bromide (PbBr) with a molar ratio of 1:1 2 ) and methyl amine chloride (MACl) were mixed and dissolved in a 4:1 volume ratio of dimethylformamide (DMF): dimethyl sulfoxide (DMSO) mixed solvent, and then the mixture was placed in a magnetic stirrer Stir until it is clear and transparent, and configure it into MAPbClBr with a mass fraction of 10%. 2 Perovskite solution.

[0039] (3) The obtained silicon substrate was placed in an ultraviolet-ozone cleaning machine for 20 min, and 70 μL of perovskite solution was taken with a pipette on the obtained silicon substrate, and the temperature was 1000 r·min at first. -1 Spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com