Silicon or silicon oxide@titanium oxide core-shell structure composite material and preparation thereof

A composite material, titanium oxide technology, used in structural parts, electrochemical generators, electrical components, etc., can solve the effect of inhibiting the expansion of internal active substances, difficult to guarantee coating uniformity, and inability to guarantee powder uniformity, etc. problems, to achieve the effect of good roasting consistency, high crystallinity, and improved electrical conductivity and ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

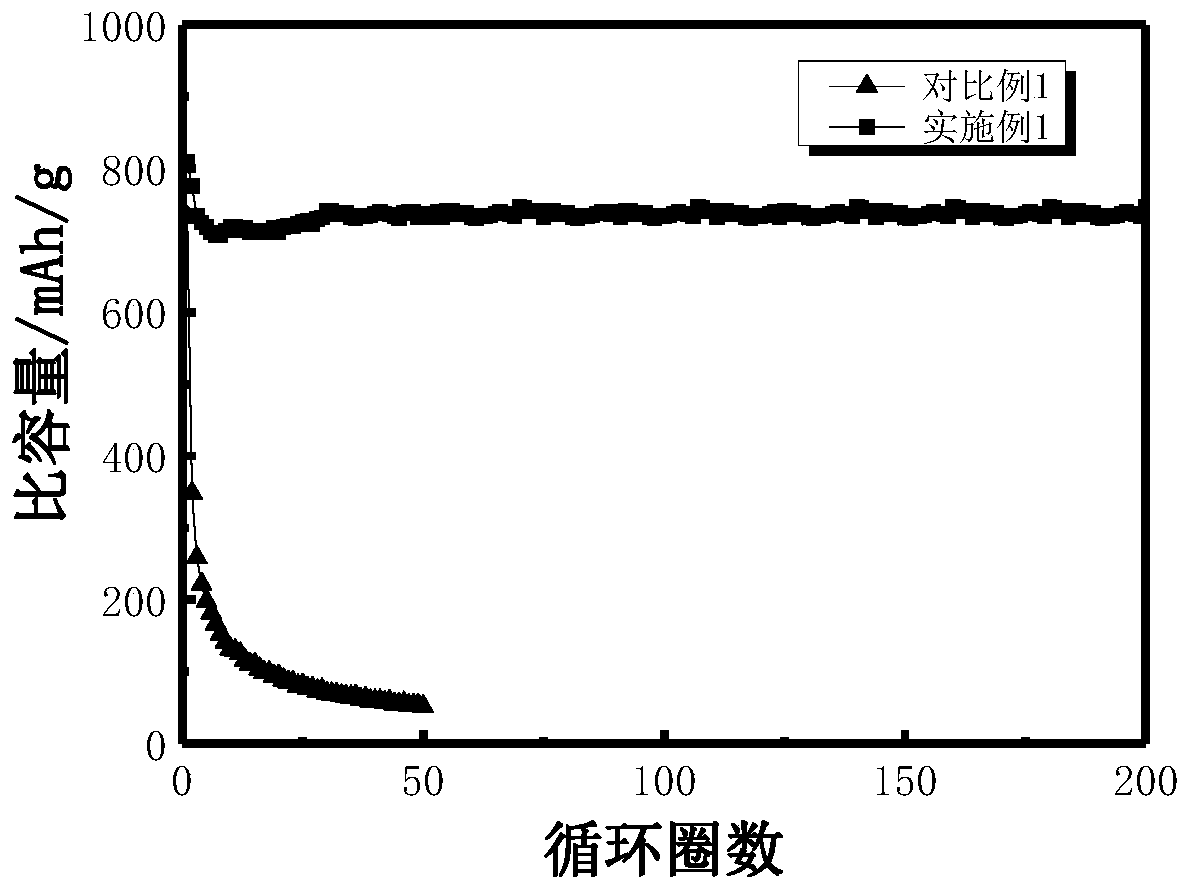

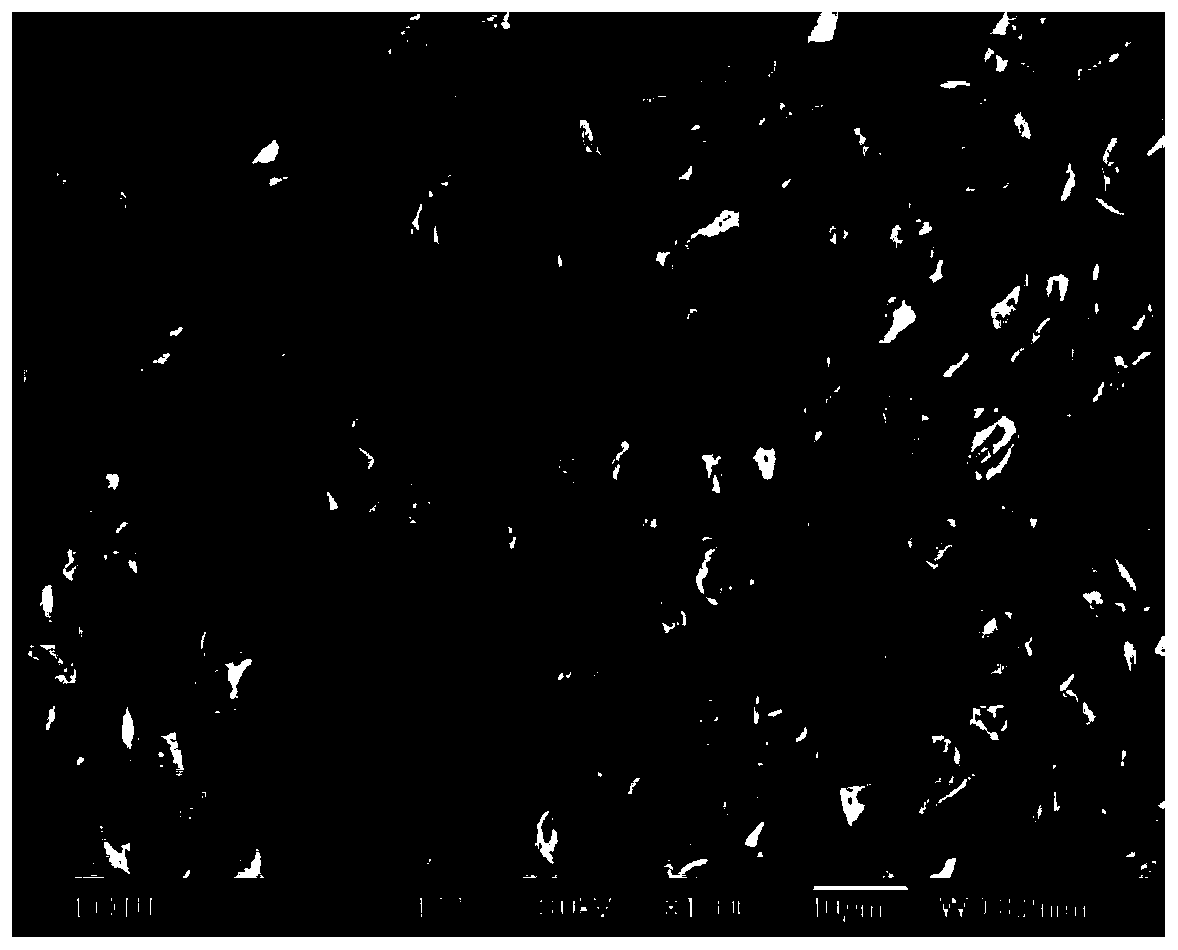

Embodiment 1

[0064] At room temperature, a certain amount of high-purity SiO x The powder is mixed with hydroxymethyl cellulose at a mass ratio of 5:1 to obtain a mixed powder, and ethanol and water are mixed at an alcohol-water volume ratio of 200:1 as a dispersion solution and the mixed powder is added to the mixer at a stirring speed of 500r / min. Then tetrabutyl titanate TBOT and ethanol were mixed at a volume ratio of 1:5 to prepare a precursor solution, and then the precursor solution was slowly injected into the stirrer through an injection device at a speed of 5 μL / min. After the injection, heat to the reaction temperature of 80°C for coating reaction, the reaction time is 100min, and the intermediate product is obtained after suction filtration. The intermediate product was put into a fluidized bed, Ar gas was introduced at a gas velocity of 100ml / min, and roasted at 800°C for 8h to obtain the final product.

[0065] Electrochemical performance test:

[0066] At room temperature,...

Embodiment 2

[0070] At room temperature, mix a certain amount of high-purity Si powder with hydroxypropyl cellulose at a mass ratio of 10:1, and mix ethanol and water at a volume ratio of 500:1 as a dispersion solution and add the mixed powder to the mixer. The stirring speed is 1000r / min. Then tetraisopropyl titanate and isopropanol were mixed at a volume ratio of 1:10 to prepare a precursor solution, which was added to the injection device and slowly injected into the stirrer at an injection speed of 10 μL / min. After the injection, heat to the reaction temperature of 95° C. for coating reaction, the reaction time is 60 minutes, and the intermediate product is obtained after suction filtration. Put the intermediate product in a fluidized bed, flow Ar gas at a gas velocity of 200ml / min, and roast at 1000°C for 6h to obtain the final product.

Embodiment 3

[0072] At room temperature, a certain amount of high-purity SiO x The powder is mixed with hydroxypropyl cellulose at a mass ratio of 2:1, and ethanol and water are mixed at an alcohol-water volume ratio of 100:1 as a dispersion solution and the mixed powder is added to the mixer at a stirring speed of 100r / min. Then tetrabutyl titanate TBOT and isopropanol were mixed at a volume ratio of 1:1 to prepare a precursor solution, which was added to the injection device and slowly injected into the stirrer at an injection speed of 1 μL / min. After the injection, heat to the reaction temperature of 60°C to carry out the coating reaction, the reaction time is 180min, and the intermediate product is obtained after suction filtration. The intermediate product was placed in a fluidized bed, Ar gas was introduced at a gas velocity of 10ml / min, and roasted at 600°C for 12h to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com