Modified small-pore molecular sieve adsorbent and its preparation method and application

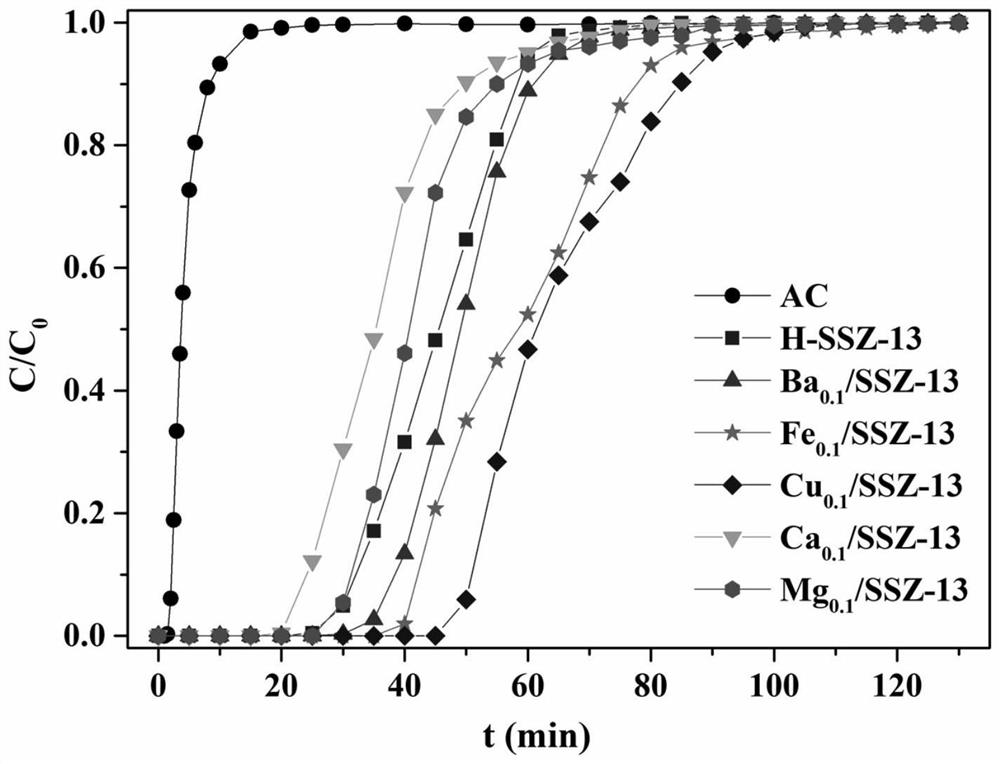

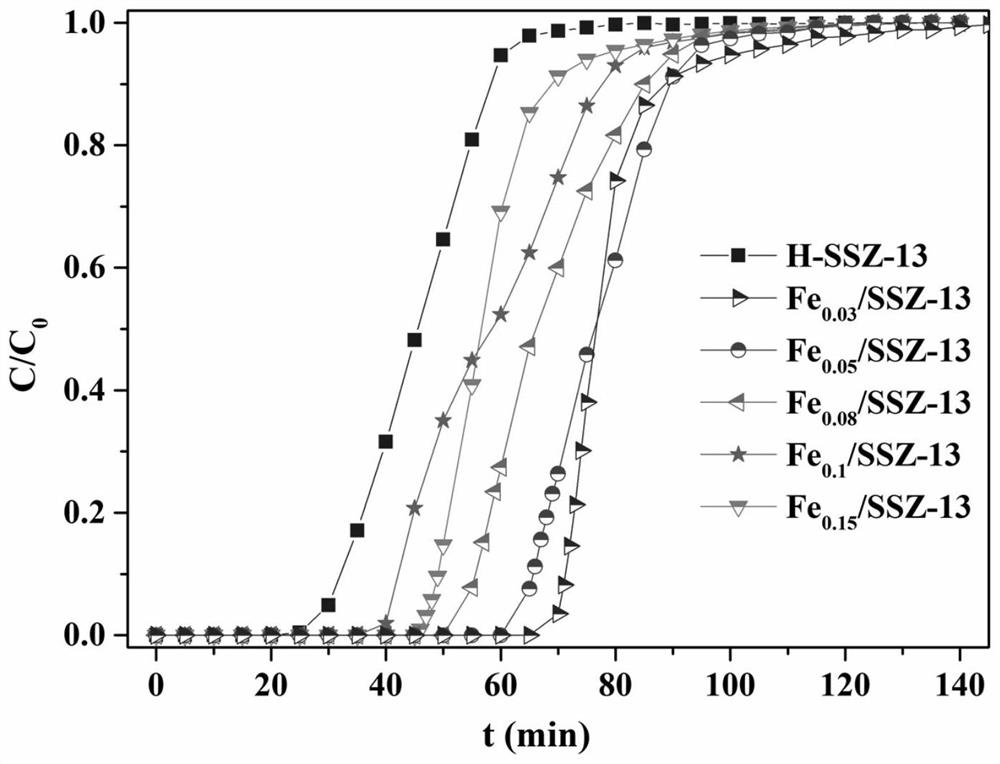

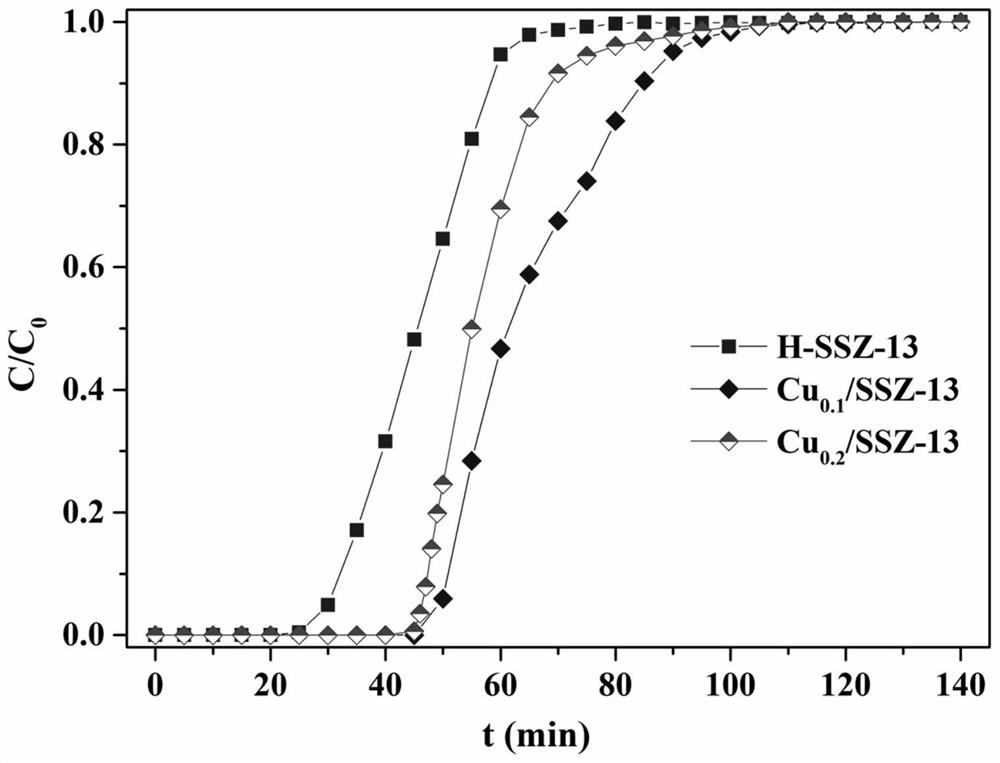

A molecular sieve and adsorbent technology, applied in the field of modified small-pore molecular sieve adsorbent and its preparation, can solve the problems of strict synthesis conditions of metal organic framework compounds, expensive production cost of graphene oxide components, damage to internal pore structure, etc. The effect of mass production, easy raw materials and long penetration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0047] The present invention provides a modified molecular sieve adsorbent, which includes: a carrier; and an active ingredient loaded on the carrier, the active ingredient includes alkaline earth metals and / or transition metals; wherein, the active ingredient and the carrier The weight ratio is 0.01-0.5; the carrier includes molecular sieves, and the average pore diameter of the molecular sieves is 0.001-2nm. The carrier of the present invention has a large amount of B acid (protonic acid), and then by using the active ingredient to modify the carrier, more L acid (aprotic acid) can be brought, thereby greatly improving the adsorption capacity of the modified molecular sieve adsorbent .

[0048] It should be noted that the modified molecular sieve adsorbent of the present invention is not a catalyst, nor does it use a chemical reaction to convert NH 3 Elimination, which is mainly used to adsorb NH 3 , the adsorbed NH 3 Did not participate in the chemical reaction, is the N...

no. 2 approach

[0058] The second embodiment of the present invention provides a method for preparing the modified molecular sieve adsorbent of the first embodiment of the present invention, comprising the following steps:

[0059] Preparation process: dissolving the carrier and the salt of the active ingredient in water to obtain a precursor slurry;

[0060] Drying process: drying the precursor slurry to obtain a dry product;

[0061] Roasting process: activating and roasting the dried product to obtain a roasted product; wherein,

[0062] The active ingredients include alkaline earth metals and / or transition metals;

[0063] The active ingredient is loaded on the carrier, and the weight ratio of the active ingredient to the carrier is 0.01-0.5, preferably 0.01-0.3, more preferably 0.02-0.2;

[0064] The carrier includes molecular sieves, and the average pore diameter of the small-pore molecular sieves is 0.001-2 nm.

[0065] Specifically, in the preparation process, the soluble active in...

no. 3 approach

[0070] The third embodiment of the present invention provides a modified molecular sieve adsorbent composition, which comprises the modified molecular sieve adsorbent described in the first embodiment or prepared by the method for preparing the modified molecular sieve adsorbent in the second embodiment modified molecular sieve adsorbent.

[0071] The third embodiment of the present invention also provides a modified molecular sieve adsorbent prepared according to the modified molecular sieve adsorbent according to the first embodiment of the present invention or the method for preparing the modified molecular sieve adsorbent according to the second embodiment of the present invention. Adsorb NH in exhaust gas 3 purposes, preferably, the waste gas includes ammonia-containing waste gas discharged from agricultural sources, industrial flue gas and motor vehicle exhaust; more preferably, the modified molecular sieve adsorbent can be used at normal temperature, such as 20-30 ° C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com