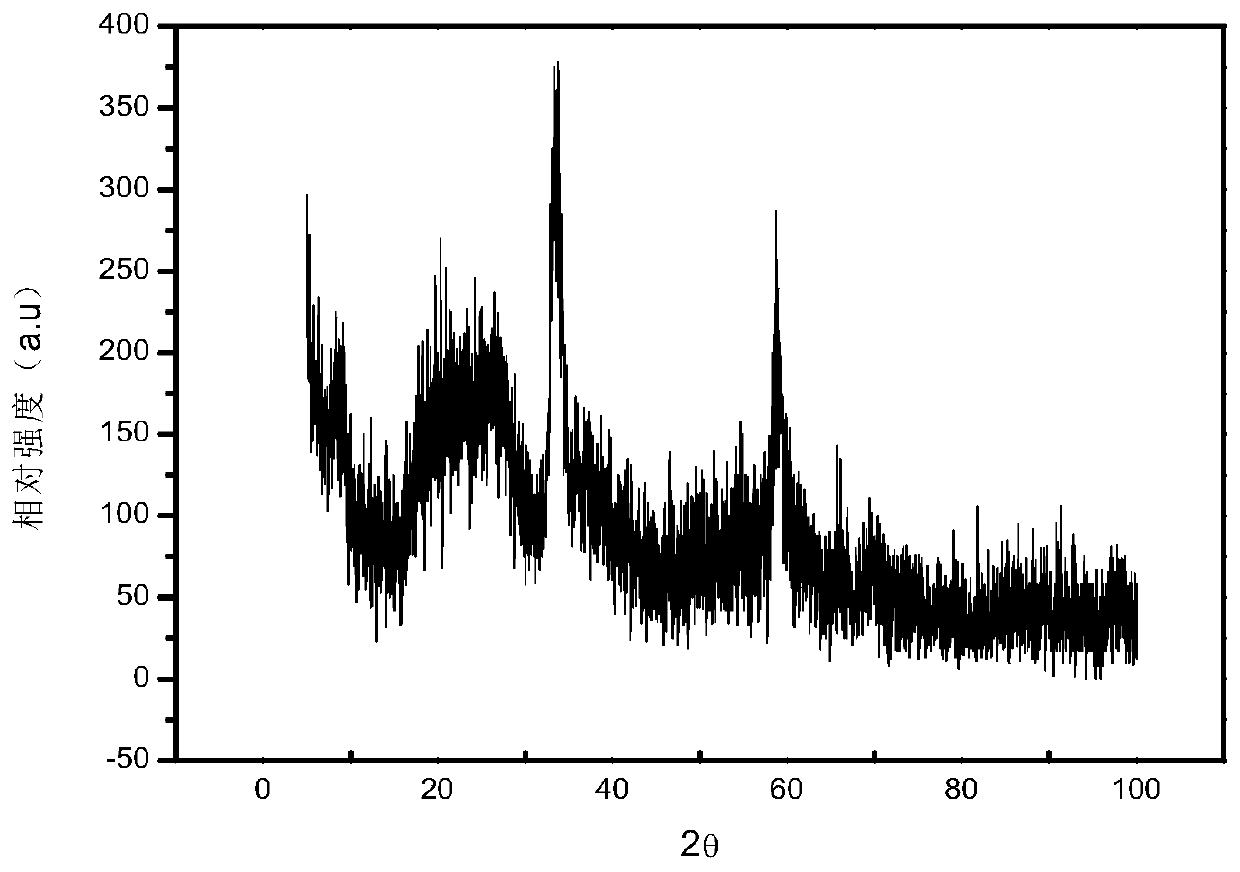

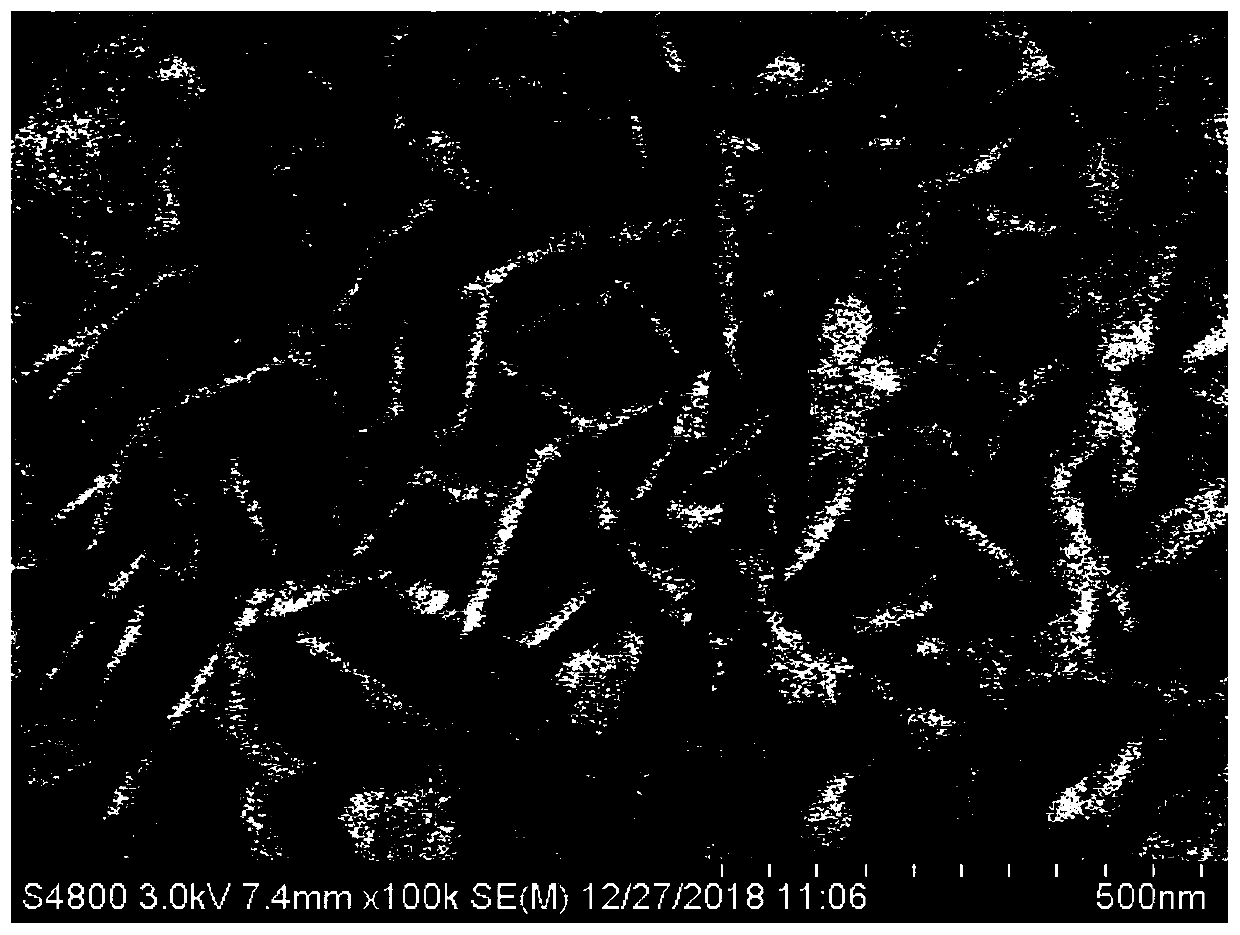

Method for synthesizing cobalt molybdate for supercapacitor electrode material

A technology for supercapacitors and synthesis methods, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of low specific capacitance and limited applications, and achieve reduced surface tension, low raw material costs, and reduced agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

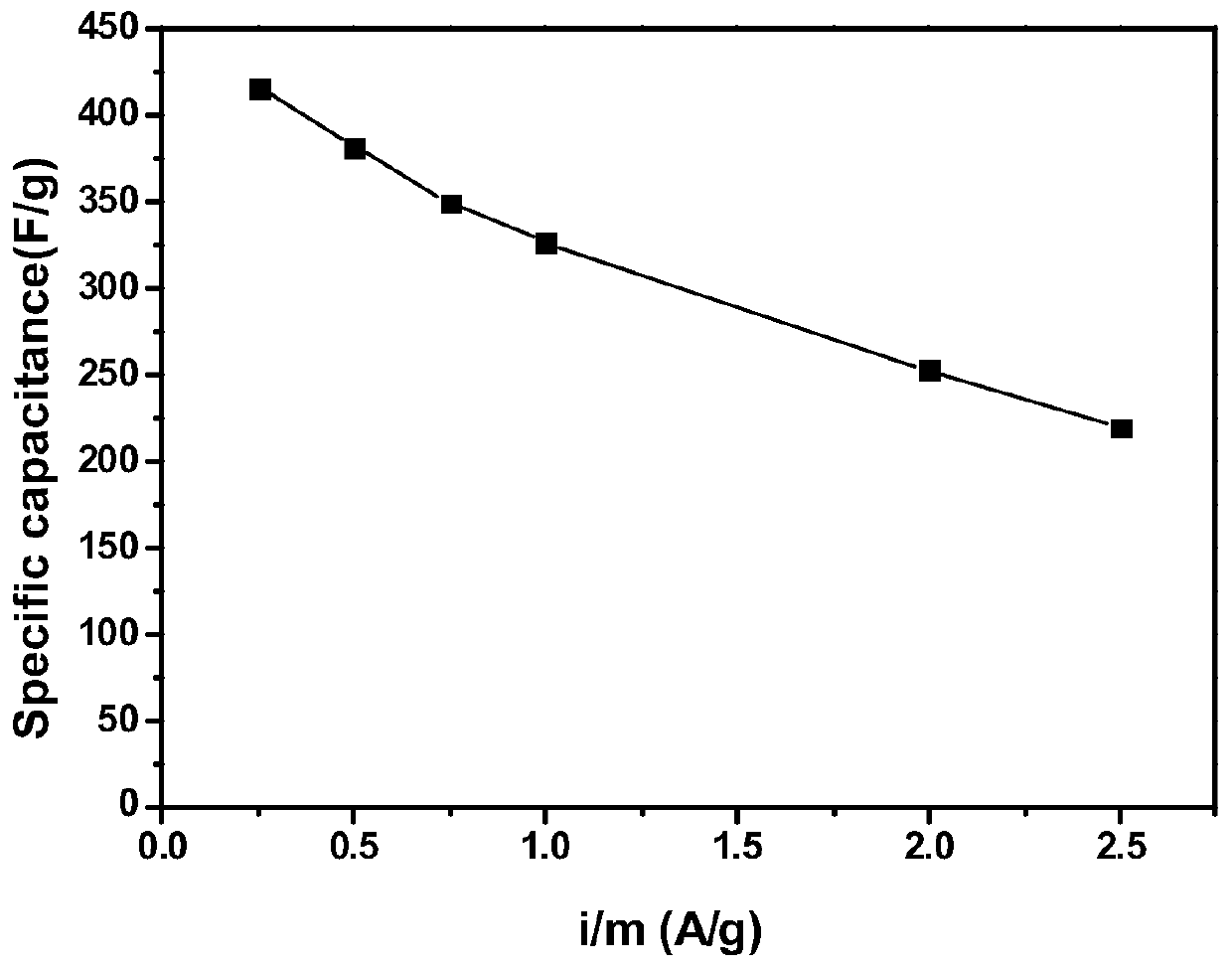

[0032] In the synthetic method of the cobalt molybdate that is used for supercapacitor electrode material of this example, at first, cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) and deionized water are mixed and dissolved at 0.002:1 according to the ratio of substances to obtain solution A, and then the morphology regulator ammonium fluoride, sodium molybdate (Na 2 MoO 4 ) and deionized water were mixed and dissolved according to the mass ratio of 0.001:0.002:1, and then the acid-base regulator tripotassium phosphate was added to adjust to neutrality to obtain solution B. Then solution A and solution B were mixed in equal volumes and subjected to precipitation reaction. The reaction temperature was 25° C., and the reaction time was 2 hours. After the reaction was completed, it was cooled and washed three times by deionized water and ethanol, respectively, and finally in a vacuum of Under the conditions of 0.8KPa and 60°C, vacuum drying was carried out for 10 hours to obtain ...

preparation example 2

[0035] In the synthetic method of the cobalt molybdate that is used for supercapacitor electrode material of the present example, at first, cobalt nitrate (Co(NO 3 ) 2 ) and deionized water are mixed and dissolved at a ratio of 0.003:1 to obtain solution A, and then the morphology regulator sodium lauryl sulfate, ammonium molybdate ((NH 4 ) 2 MoO 4 ) and deionized water were mixed and dissolved according to the mass ratio of 0.001:0.003:1, and then an acid-base regulator potassium citrate was added to adjust to neutrality to obtain solution B. Then solution A and solution B were mixed in equal volumes to carry out precipitation reaction. The reaction temperature was 40°C and the reaction time was 6 hours. After the reaction was completed, it was cooled and washed three times by centrifugation with deionized water and ethanol. Under the conditions of 0.8KPa and 60°C, vacuum drying was carried out for 10 hours to obtain cobalt molybdate.

[0036] The cobalt molybdate electrode...

preparation example 3

[0038] In the synthetic method of the cobalt molybdate that is used for supercapacitor electrode material of this example, at first, cobalt bromide (CoBr 2 ) and deionized water are mixed and dissolved at a ratio of 0.003:1 to obtain solution A, and then the morphology regulator hexadecyltrimethylammonium bromide, nickel molybdate (NiMoO 4 ) and deionized water were mixed and dissolved according to the mass ratio of 0.002:0.004:1, and then the acid-base regulator sodium citrate was added to adjust to neutrality to obtain solution B. Then, solution A and solution B were mixed in equal volumes and subjected to precipitation reaction. The reaction temperature was 80° C., and the reaction time was 8 hours. After the reaction was completed, it was cooled and washed three times by deionized water and ethanol, respectively, and finally in a vacuum of Under the conditions of 0.8KPa and 60°C, vacuum drying was carried out for 10 hours to obtain cobalt molybdate.

[0039] The cobalt mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com