Quantum dot film, preparation method thereof, QLED (Quantum dot Light-Emitting Diode) device and preparation method thereof

A technology for quantum dots and quantum dots to emit light, applied in the field of flat panel display, can solve the problem that the solubility and dispersive conductivity of quantum dots are difficult to achieve a balance, improve stability and carrier transport capacity, improve overall performance, and achieve scale Effects of chemical and industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

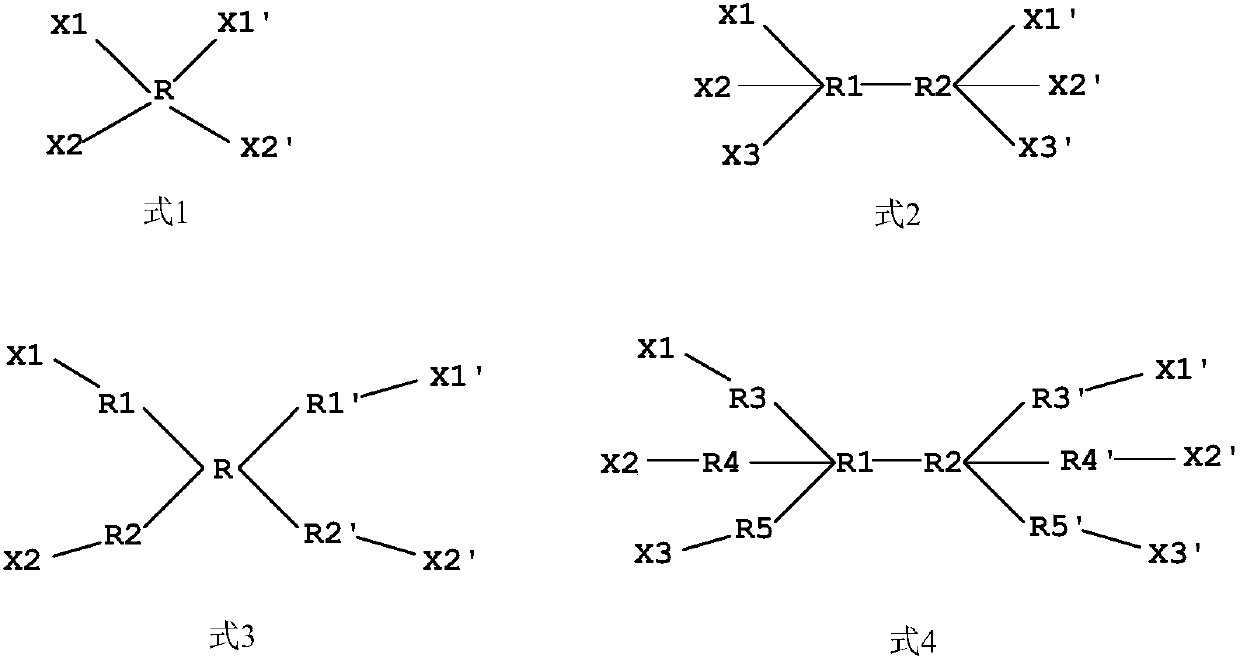

[0037] Among them, Formula 1, Formula 2, Formula 3, and Formula 4 contain at least one conjugated group, specifically, in Formula 1, R is a conjugated group; in Formula 2, at least one of R1 and R2 is a conjugated group Group; in formula 3, at least one of R, R1, R1', R2, R2' is a conjugated group; in formula 4, R1, R1', R2, R2', R3, R3', R4, R4 At least one of ', R5, R5' is a conjugated group. Conjugated groups have been described above, for example, R, R1, R1', R2, R2', R3, R3', R4, R4', R5, R5' can be independently selected from unsaturated hydrocarbon groups or hydrocarbon derivatives, such as alkenes group, alkyne group, aryl group, heteroaryl group and their derivatives, etc. X1, X1', X2, X2', X3, X3' are active functional groups, functional groups capable of chelating with the surface of quantum dots, preferably, the active functional groups include halogen atoms, -SH, -COOH, -NH 2 , -OH, -NO 2 、-SO 3 At least one of H, phosphine group, phosphoric acid group, ether ...

Embodiment 1

[0076] A method for preparing a quantum dot film, comprising the following steps:

[0077] Provide a CdSe quantum dot prefabricated film, transfer the quantum dot prefabricated film into a vacuum chamber, and feed 1,2-ethanedithiol gas, wherein the internal pressure of the vacuum chamber is 5Pa, 1,2-ethanedithiol The partial pressure of the gas is 1 Pa, the temperature inside the chamber is 25°C, and the treatment time is 30 minutes. After the treatment, it is taken out to obtain a CdSe quantum dot film whose ligand is substituted with 1,2-ethanedithiol.

Embodiment 2

[0079] A method for preparing a positive-type structure quantum dot light-emitting diode, comprising the following steps:

[0080] Print PEDOT hole injection layer, TFB hole transport layer, and CdSe quantum dot prefabricated film coated with oleic acid ligand on the ITO anode in sequence;

[0081] The quantum dot prefabricated film prepared above is transferred to a vacuum chamber, and 1,4-benzenedithiol gas is introduced, wherein the internal pressure of the chamber is 5Pa, and the partial pressure of 1,4-benzenedithiol gas is 1Pa. The temperature inside the chamber is 25°C, and the treatment time is 30 minutes. After the treatment, it is taken out to obtain a CdSe quantum dot light-emitting layer cross-linked by 1,4-benzenedithiol ligand;

[0082] Print a ZnO electron transport layer on the ligand-conjugated and cross-linked quantum dot light-emitting layer obtained above, and finally vapor-deposit an Al cathode to obtain a positive-type structure quantum dot light-emitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com