Carbon sphere coated cobalt selenide nano-composite material and preparation method and application thereof

A cobalt selenide nanometer and nanomaterial technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as cycle performance degradation, impact on battery cycle performance and rate performance, electrode structure collapse, etc., to achieve good electrochemical performance , excellent cycle stability, the effect of promoting close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Dissolve 0.6 mol of cobalt nitrate and 0.2 mol of selenous acid in 80 mL of isopropanol, then add glycerol with a volume of 25% of the above solution, stir magnetically at 40°C for about 1 hour, and then conduct solvothermal at 120°C Reaction, after 12 hours of reaction, the reaction product was taken out, centrifuged, washed with ethanol, dried, and then carbonized. The carbonization reaction conditions were under nitrogen atmosphere, the heating rate was 3°C / min, the reaction temperature was 400°C, and the reaction time was 4h. , to obtain cobalt selenide nanocomposites wrapped in carbon spheres.

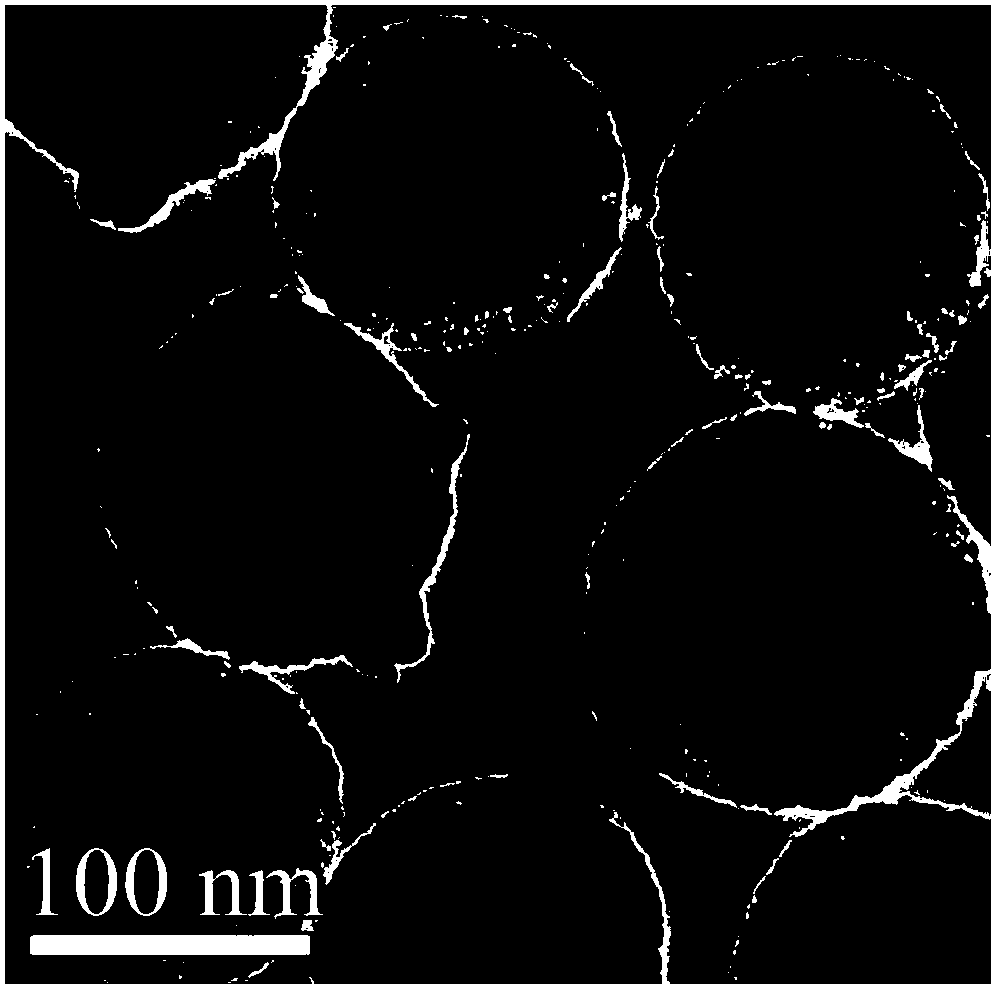

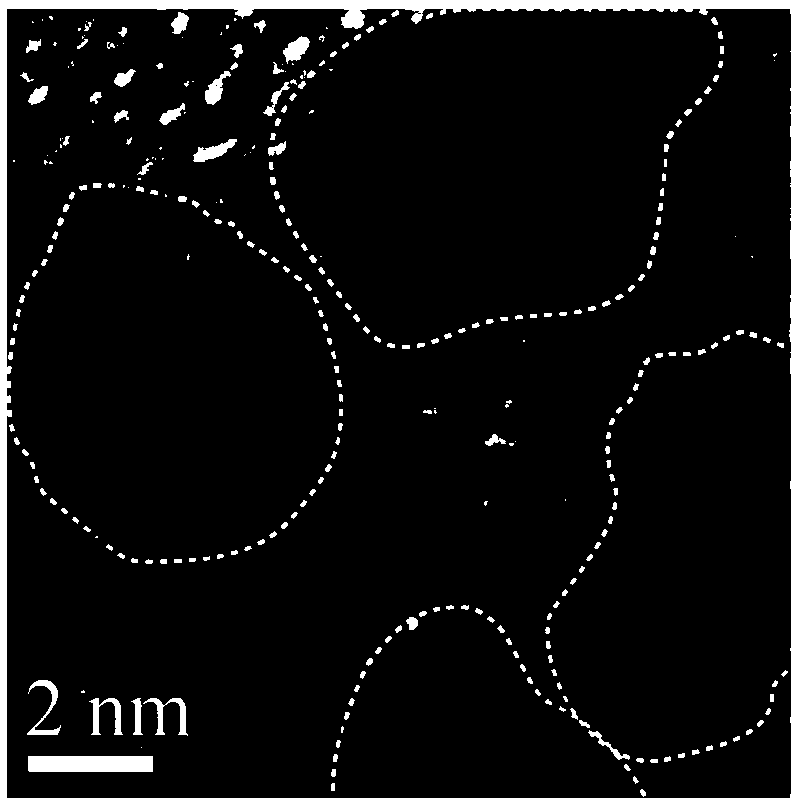

[0034] Such as figure 1 As shown, the cobalt selenide nanocomposite material wrapped by carbon spheres prepared above is a spherical material with a particle size of about 100nm, wherein the particle size of the cobalt selenide nanomaterial is 3-10nm, such as figure 2 shown.

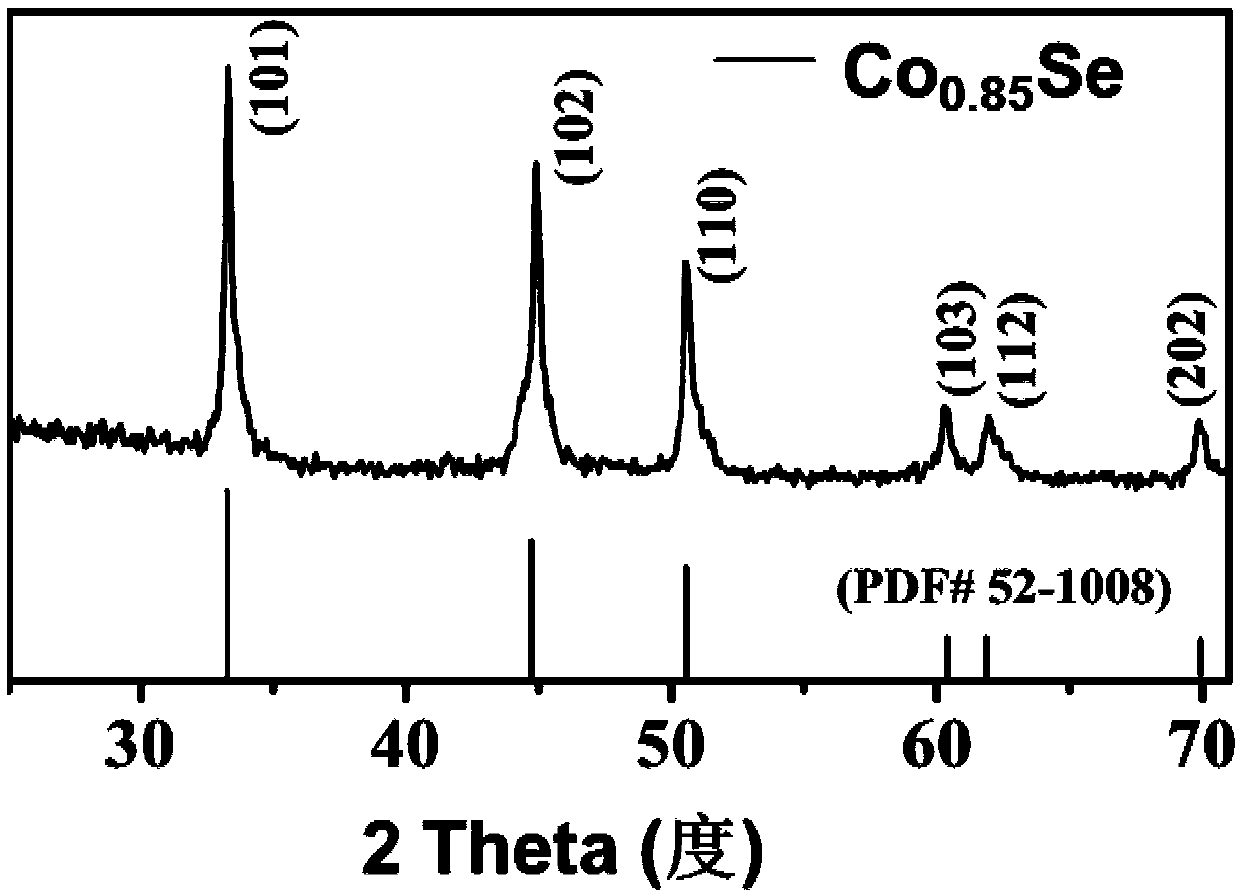

[0035] Such as image 3 As shown, the positions and intensities of the diffraction peaks revea...

Embodiment 2

[0038] Dissolve 0.6 mol of cobalt nitrate and 0.2 mol of selenous acid in 80 mL of isopropanol, then add glycerol with 20% volume of the above solution, stir magnetically at 40°C for about 1 hour, and then conduct solvothermal at 120°C Reaction, after 12 hours of reaction, the reaction product was taken out, centrifuged, washed with ethanol, dried, and then carbonized. The carbonization reaction conditions were under nitrogen atmosphere, the heating rate was 3°C / min, the reaction temperature was 400°C, and the reaction time was 4h. , to obtain cobalt selenide nanocomposites wrapped in carbon spheres.

[0039] Such as Figure 5 As shown, the scanning electron microscope image shows that the particle size of the above material after carbonization is about 300nm.

Embodiment 3

[0041] Dissolve 0.6 mol of cobalt nitrate and 0.2 mol of selenous acid in 80 mL of isopropanol, then add glycerol with a volume of 13% of the above solution, stir magnetically at 40°C for about 1 hour, and then conduct solvothermal at 120°C Reaction, after 12 hours of reaction, the reaction product was taken out, centrifuged, washed with ethanol, dried, and then carbonized. The carbonization reaction conditions were under nitrogen atmosphere, the heating rate was 3°C / min, the reaction temperature was 400°C, and the reaction time was 4h. , to obtain cobalt selenide nanocomposites wrapped in carbon spheres.

[0042] Such as Figure 6 As shown, the scanning electron microscope image shows that the particle size of the above material after carbonization is about 500nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com