Silane modified graphene oxide modified polycarboxylic acid reducer and preparation method thereof

A technology of graphene chemistry and silane modification, which is applied in the field of polycarboxylate water reducer and its preparation, can solve the failure of the interaction between graphene oxide and polycarboxylate water reducer, and affect the uniform dispersion and effective effect of graphene oxide , hinder the uniform dispersion of graphene oxide, etc., to achieve super adsorption-dispersibility, improve the effect of enhancement and optimization, and the effect of low total porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

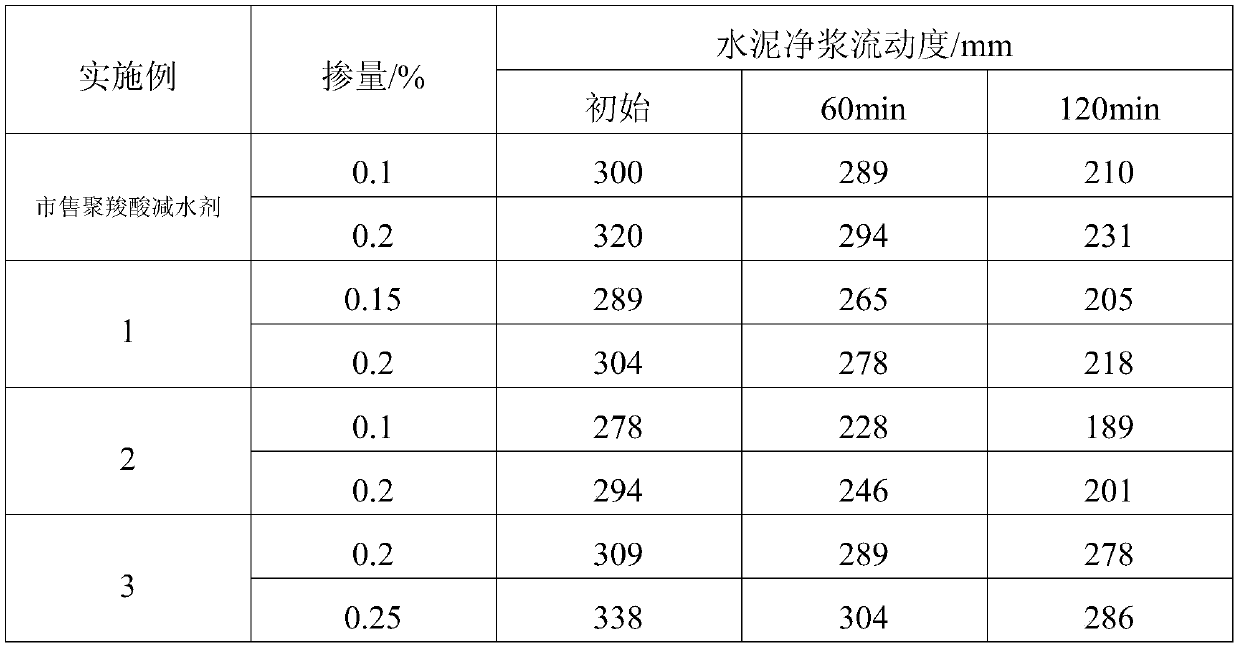

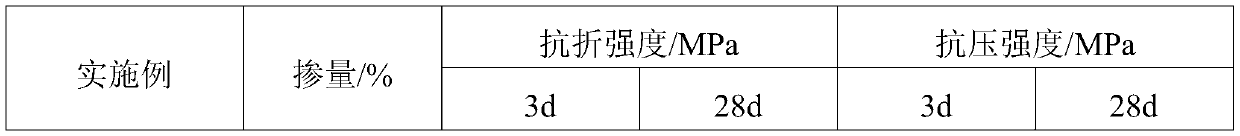

Examples

Embodiment 1

[0029] A silane-modified graphene oxide chemically modified polycarboxylate water reducer, made of the following components in parts by weight: 100 parts of isobutylene alcohol polyoxyethylene ether, γ-methacryloxypropyl trimethoxy 12 parts of silane, 5 parts of graphene oxide, 2 parts of ammonium persulfate, 1.0 part of hydrogen peroxide, 0.5 part of L-ascorbic acid, and 0.8 part of mercaptopropionic acid.

[0030] The concrete preparation method of above-mentioned water reducing agent is as follows:

[0031] Mix γ-methacryloxypropyl trimethoxysilane with 50% ethanol solution evenly, and stir magnetically for 1 hour in a water bath environment at 30-40°C, until γ-methacryloxypropyl trimethoxysilane The methoxysilane in the base silane is completely hydrolyzed into silanol groups; graphene oxide is added to the mixed solution, and ultrasonically dispersed for 1 hour until the graphene oxide is uniformly dispersed; the mixed solution is magnetically stirred and heated in a wate...

Embodiment 2

[0033] A sulfate-resistant competitive adsorption type silane-modified polycarboxylate water reducer, which is made of the following components in parts by weight: 100 parts of isobutylene alcohol polyoxyethylene ether, γ-methacryloxypropyl trimethoxy 15 parts of silane, 4 parts of graphene oxide, 0.5 part of ammonium persulfate, 1.2 parts of hydrogen peroxide, 1.0 part of L-ascorbic acid, and 0.8 part of mercaptopropionic acid.

[0034] The concrete preparation method of above-mentioned water reducing agent is as follows:

[0035] Mix γ-methacryloxypropyl trimethoxysilane with 50% ethanol solution evenly, and stir magnetically for 1 hour in a water bath environment at 30-40°C, until γ-methacryloxypropyl trimethoxysilane The methoxysilane in the base silane is completely hydrolyzed into silanol groups; graphene oxide is added to the mixed solution, and ultrasonically dispersed for 1 hour until the graphene oxide is uniformly dispersed; the mixed solution is magnetically stirre...

Embodiment 3

[0037] A sulfate-resistant competitive adsorption type silane-modified polycarboxylate water reducer, made of the following components in parts by weight: 100 parts of isobutylene alcohol polyoxyethylene ether, γ-methacryloxypropyl trimethyl 14 parts of oxysilane, 4.5 parts of graphene oxide, 1.0 part of ammonium persulfate, 1.1 parts of hydrogen peroxide, 0.9 parts of L-ascorbic acid, and 1.3 parts of mercaptopropionic acid.

[0038] The concrete preparation method of above-mentioned water reducing agent is as follows:

[0039]Mix γ-methacryloxypropyl trimethoxysilane with 50% ethanol solution evenly, and stir magnetically for 1 hour in a water bath environment at 30-40°C, until γ-methacryloxypropyl trimethoxysilane The methoxysilane in the base silane is completely hydrolyzed into silanol groups; graphene oxide is added to the mixed solution, and ultrasonically dispersed for 1 hour until the graphene oxide is uniformly dispersed; the mixed solution is magnetically stirred an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com