Fiber-reinforced cement-based materials for 3D printing and its preparation, performance evaluation and application

A fiber-reinforced cement and 3D printing technology, which is applied in the analysis of materials, additive processing, and flow characteristics, can solve the problems of concrete tensile and shear strength not being improved, increasing construction complexity, and reducing the degree of mechanical automation. Achieve the effect of maintaining early mechanical properties, accelerating setting time, and maintaining buildability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

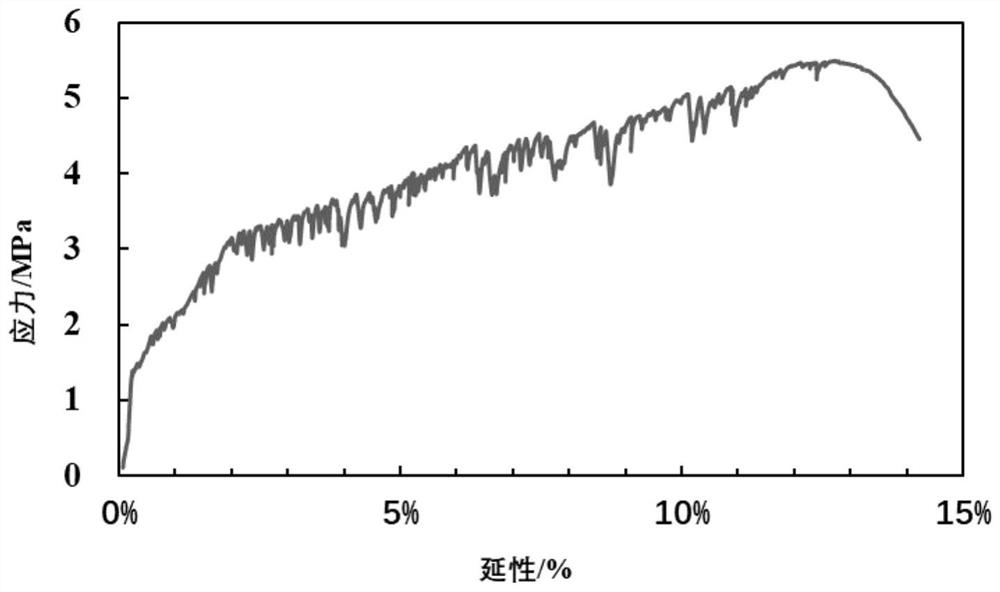

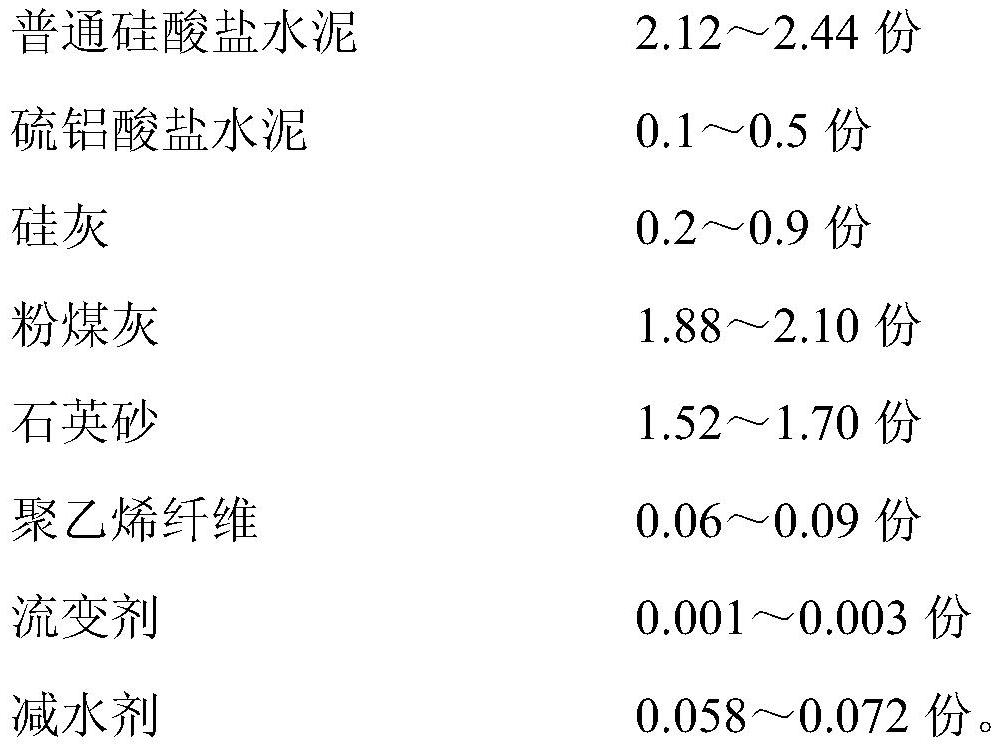

[0041] A fiber-reinforced cement-based material for 3D printing, which has ultra-high toughness, and includes the following components in parts by weight: 2.44 parts of ordinary Portland cement, 0.50 part of sulphoaluminate cement, 0.40 part of silica fume, and powdered coal 1.88 parts of ash, 1.70 parts of quartz sand, 0.09 parts of polyethylene fiber, 0.003 parts of rheological agent, and 0.072 parts of water reducing agent.

[0042] in:

[0043] The 28-day flexural strength of the ordinary Portland cement is 10.6MPa, the 28-day compressive strength is 52.8MPa, and the specific surface area is 362m 2 / kg, the density is 3.17g / cm 3 , the water consumption of the standard consistency is 24.8%, the initial setting time is 140min, the final setting time is 245min, the loss on ignition is 3.24%, and the magnesium oxide content is 0.87%.

[0044] The loss on ignition of the sulphoaluminate cement is 11.76%, and the 1-day compressive strength is 81.8MPa. It contains red mud, alum...

Embodiment 2

[0064] A fiber-reinforced cement-based material for 3D printing, which has ultra-high toughness, and includes the following components in parts by weight: 2.36 parts of ordinary Portland cement, 0.40 parts of sulphoaluminate cement, 0.75 parts of silica fume, and powdered coal Ash 1.90 parts, quartz sand 1.60 parts, polyethylene fiber 0.08 parts, rheological agent 0.002 parts, water reducer 0.070 parts.

[0065] The 28-day flexural strength of the ordinary Portland cement is 10.6MPa, the 28-day compressive strength is 52.8MPa, and the specific surface area is 362m 2 / kg, the density is 3.17g / cm 3 , the water consumption of the standard consistency is 24.8%, the initial setting time is 140min, the final setting time is 245min, the loss on ignition is 3.24%, and the magnesium oxide content is 0.87%.

[0066] The loss on ignition of the sulphoaluminate cement is 11.76%, and the 1-day compressive strength is 81.8MPa. It contains red mud, aluminum ash, carbide slag and desulfurize...

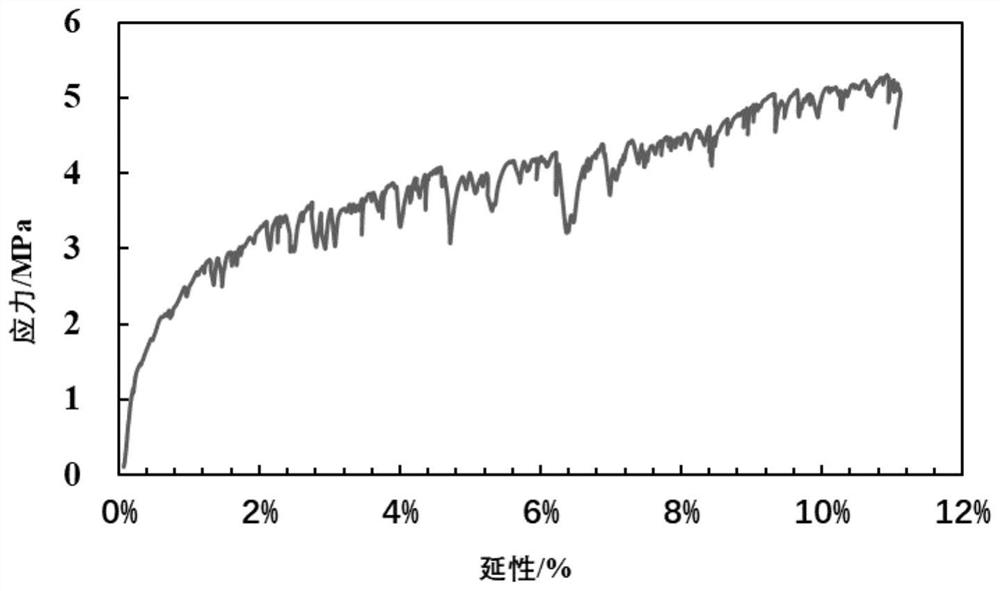

Embodiment 3

[0086] A fiber-reinforced cement-based material for 3D printing, which has ultra-high toughness, and includes the following components in parts by weight: 2.28 parts of ordinary Portland cement, 0.30 parts of sulphoaluminate cement, 0.20 parts of silica fume, and powdered coal Ash 1.96 parts, quartz sand 1.66 parts, polyethylene fiber 0.07 parts, rheological agent 0.002 parts, water reducer 0.066 parts.

[0087] The 28-day flexural strength of the ordinary Portland cement is 10.6MPa, the 28-day compressive strength is 52.8MPa, and the specific surface area is 362m 2 / kg, the density is 3.17g / cm 3 , the water consumption of the standard consistency is 24.8%, the initial setting time is 140min, the final setting time is 245min, the loss on ignition is 3.24%, and the magnesium oxide content is 0.87%.

[0088] The loss on ignition of the sulphoaluminate cement is 11.76%, and the 1-day compressive strength is 81.8MPa. It contains red mud, aluminum ash, carbide slag and desulfurize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com