Method for preparing m-chlorophenol

A technology of chlorophenol and chloroaniline, which is applied in the field of m-chlorophenol preparation, can solve the problems of high cost of dichlorosulfuryl, corrosion of production equipment, low production capacity, etc., and achieve easy industrial large-scale use and reduce the amount of waste acid produced , The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

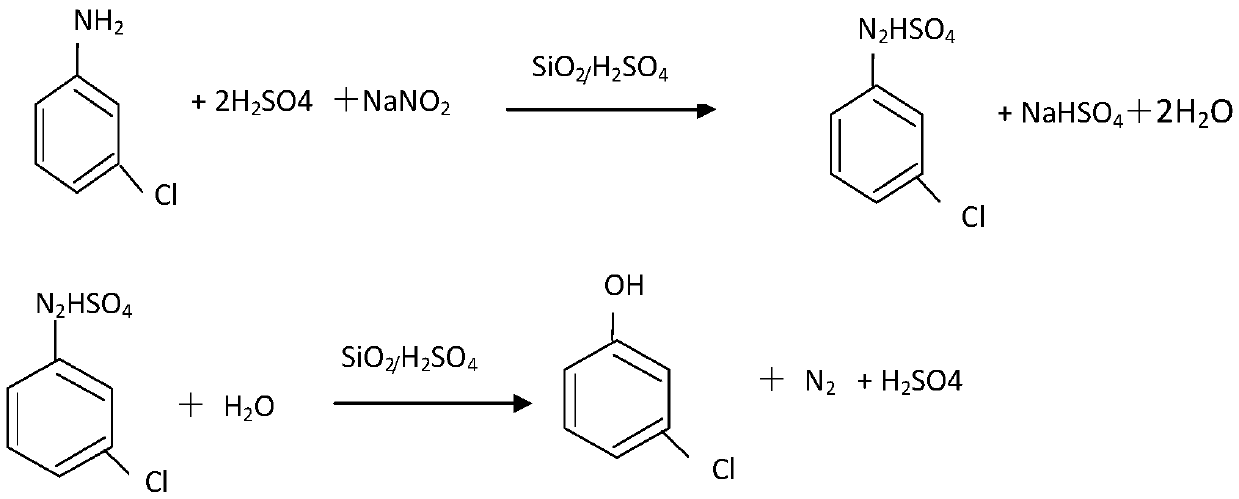

Method used

Image

Examples

Embodiment 1

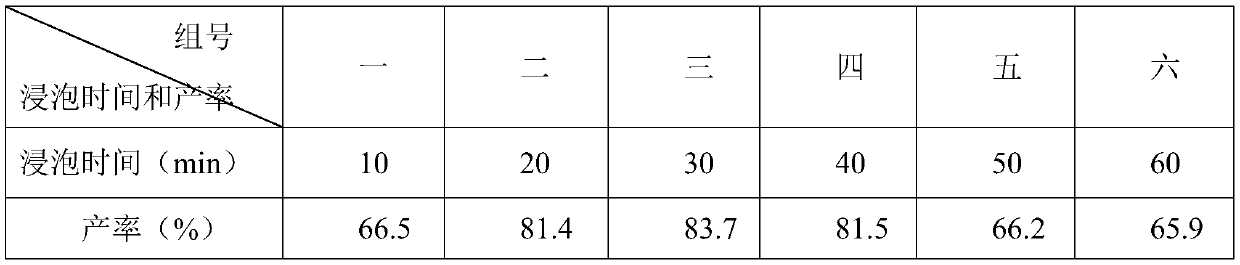

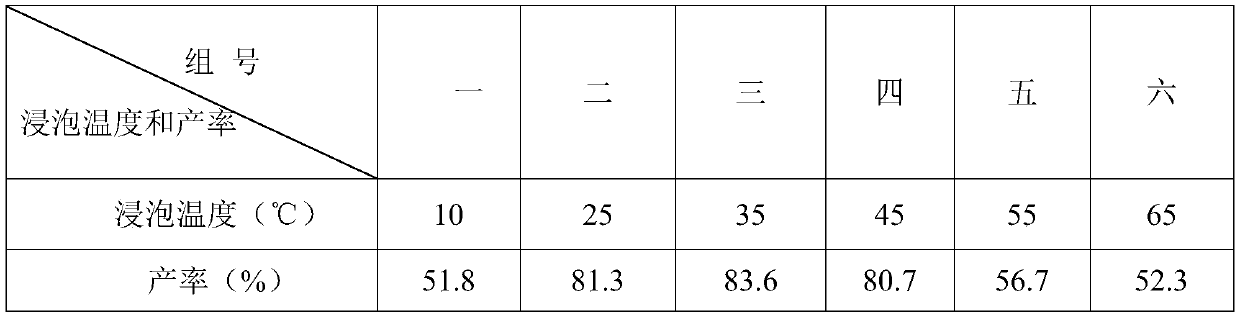

[0022] Preparation of the silica gel-supported catalyst: at 40° C., 162 kg of silica gel was soaked in 98% sulfuric acid for 20 minutes, and then the acid washed off the surface was taken out and dried to obtain 434 kg of silica gel-supported catalyst.

[0023] Diazotization: Add 300kg of water into the reaction kettle, start stirring at 62 rpm, then add 310kg of silica gel-loaded sulfuric acid catalyst, cool with ice-salt water to make the temperature 0°C, and then add 82kg of m-chloroaniline at one time And 150kg of sodium nitrite solution of 20% by mass percentage, control temperature at 15 ℃. After adding, cool it with ice-salt water to lower the temperature below 10°C. After reacting at 10°C for 4 hours, measure the blueness with starch potassium iodide test paper, adjust it with urea solution until it does not turn blue, and filter it with an 80-mesh filter cloth , the filtrate was prepared for hydrolysis, and the filtered silica gel was loaded with a sulfuric acid catal...

Embodiment 2

[0027] Preparation of silica gel supported catalyst: at 37°C, soak 210.6 kg of silica gel in 98% sulfuric acid for 35 minutes, take out the acid washed off the surface and dry to obtain 564.2 kg of silica gel supported catalyst.

[0028] Diazotization: Add 300kg of water into the reaction kettle, start stirring, and the rotation speed is 62 rpm, then add 310kg of silica gel-loaded sulfuric acid catalyst, cool it with ice-salt water to make the temperature 10°C, and then add 82kg of m-chloroaniline and mass Percentage 28% sodium nitrite solution 150kg, control temperature at 35 ℃. After the addition, the temperature was lowered to below 10°C by cooling with ice-salt water. After reacting at 10°C for 5.5 hours, it turned blue with starch potassium iodide test paper, then adjusted with urea solution until it did not turn blue, and filtered with 80-mesh filter cloth , the filtrate was prepared for hydrolysis, and the filtered silica gel was loaded with a sulfuric acid catalyst, pu...

Embodiment 3

[0032] Preparation of silica gel-supported catalyst: at 45° C., 178.2 kg of silica gel was soaked in 98% sulfuric acid for 30 minutes, and then the acid washed off the surface was taken out and dried to obtain 477.4 kg of silica gel-supported catalyst.

[0033] Diazotization: Add 328kg of water into the reaction kettle, start stirring at 62 rpm, then add 328kg of silica gel-supported sulfuric acid catalyst, cool it with low-temperature ethylene glycol to make the temperature 5°C, and then add 82kg of sulfuric acid catalyst at a time Chloroaniline and 30% sodium nitrite solution of mass percentage 164kg, control temperature at 25 ℃. After the addition, the temperature was lowered to below 10°C by cooling with ice-salt water. After reacting at 10°C for 5 hours, it turned blue with starch potassium iodide test paper, then adjusted with urea solution until it did not turn blue, and filtered with 80-mesh filter cloth , the filtrate was prepared for hydrolysis, and the filtered sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com