A modified polyurea coating

A polyurea and coating technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of nanoparticle dispersion, unreached lifting range, dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

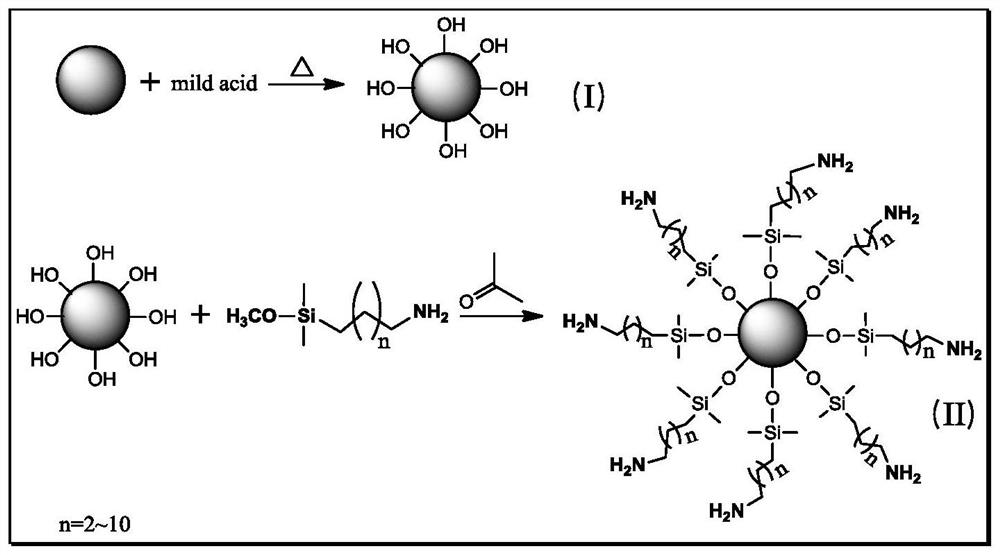

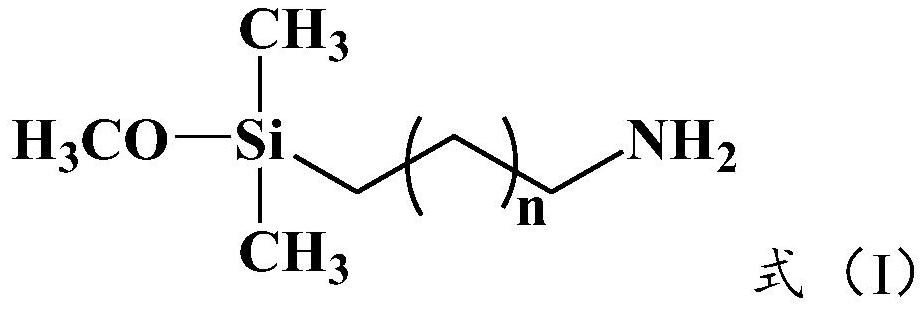

[0043] Weigh 1g of nano-silica particles, add them to 50ml of oxalic acid aqueous solution with a mass concentration of 20%, and heat and stir in a water bath at 60°C for 6 hours; after standing to precipitate, silica nanoparticles rich in hydroxyl groups on the surface are obtained. Wash it repeatedly with saturated sodium bicarbonate solution to neutrality, then add 50ml of methoxydimethylbutylaminosilane acetone solution with a concentration of 0.02g / ml, stir for 1h, and then add dropwise 0.02g of Dibutyltin laurate, react at room temperature for 2 hours, and distill off acetone under reduced pressure to obtain silane-modified silica nanoparticles with amino groups.

[0044] From the results of infrared analysis, it can be seen that 1648, 3450cm -1 The location appeared - NH 2 Vibration peak, 470cm -1 Si-O vibration peaks appear at the position, 800, 1260cm -1 position appears -Si(CH 3 ) 2 - Vibration peaks.

[0045] Through acid-base titration measurement, the surfac...

Embodiment 2

[0049] Weigh 1g of nano-zinc oxide particles, add it to 50ml of 30% hydrofluoric acid aqueous solution, heat and stir in a water bath at 60°C for 6 hours; after static precipitation, zinc oxide nanoparticles rich in hydroxyl groups on the surface are obtained. Wash it repeatedly with sodium bicarbonate solution to neutrality, then add 50ml of acetone solution of methoxydimethylhexylaminosilane with a concentration of 0.01g / ml, stir for 1h, and then add dropwise 0.02g of Dibutyltin laurate, react at room temperature for 2 hours, and distill off acetone under reduced pressure to obtain silane-modified nano-zinc oxide particles with amino groups.

[0050] After calculation, the areal density of the nano-zinc oxide particles modified with silane-terminated amino groups obtained in Example 2 is 14 nmol / cm 2 .

[0051] Weighed 0.5 g of silane-modified nano-zinc oxide particles with amino groups and 55 g of isocyanate IPDI (isophorone diisocyanate) and mixed them evenly to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com