A kind of modified polyurea coating

A modification and polyurea technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems that materials cannot be modified, graphene cannot be dispersed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

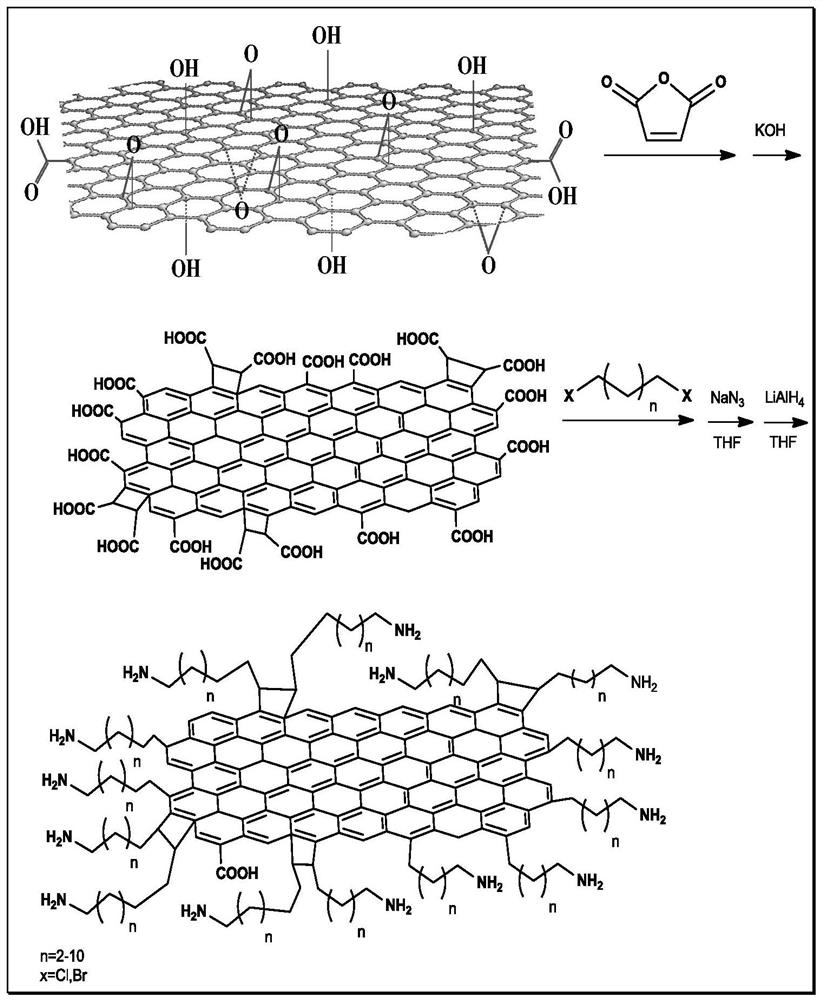

[0064] First, the graphite or graphene material is oxidized by the Hummers method to obtain graphene oxide. 0.2 g of graphene oxide was ultrasonically dispersed in 100 ml of tetrahydrofuran solution for 15 minutes, and a graphene oxide colloidal solution was obtained after ultrasonic dispersion.

[0065] Then add 0.4 g of maleic anhydride to the graphene oxide colloidal solution, and ultrasonically disperse for 15 minutes. The graphene oxide / maleic anhydride / THF mixture was irradiated in a Co-60 source with a radiation dose of 40 kGy and a dose rate of 25 Gy / min. The modified graphene oxide is obtained after the insoluble matter in the mixed solution after irradiation is suction-filtered, washed to neutrality and dried.

[0066] Weigh 0.2 g of modified graphene oxide, soak in 1 mmol / L KOH aqueous solution and 1 mmol / L hydrochloric acid solution for 5 minutes and 10 minutes respectively for hydrolysis. After the product was suction-filtered and washed with deionized water to ...

Embodiment 2~ Embodiment 5

[0073] According to the method of Example 1, the amino-modified graphene of component B in Table 1 was prepared. The components and test results of the modified polyurea coatings prepared in Examples 2 to 5 are shown in Table 1.

[0074]

[0075]

[0076] Note: The tensile test sample is casted with the polyurea coating in the embodiment, the size is 50×5×2 (mm×mm×mm), the curing temperature is room temperature, and the curing time is 48h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com