Lipase composition and application thereof

A technology of lipase and composition, which is applied in the field of enzyme engineering, can solve problems such as few structure and catalytic substrate affinity and activity, achieve good promotion and application value, speed up the initial reaction speed, and smooth the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a kind of preparation method of fatty acid methyl ester, it is to use lipase composition as above to prepare fatty acid methyl ester, and concrete steps are as follows:

[0040] 1) Take kitchen waste grease or deodorized vegetable oil distillate and place it in the reaction device, add lye, adjust the pH to 5-6.5, and stir evenly at 30-45°C for later use; wherein, the lye is 0-560ppm NaOH;

[0041] 2) Weighing 0.1% to 0.6% lipase composition according to the mass ratio, adding it to purified water or tap water, mixing evenly, and then adding it to the soybean oil deodorized distillate in step 1), and continuing the reaction;

[0042] 3) During the reaction process, add 1.5-2 equivalents of methanol several times, and continue to stir and react at a speed of 10-300r / min for 2-24h. The oil sample is separated into layers, the oil sample is taken, and the fatty acid methyl ester is obtained.

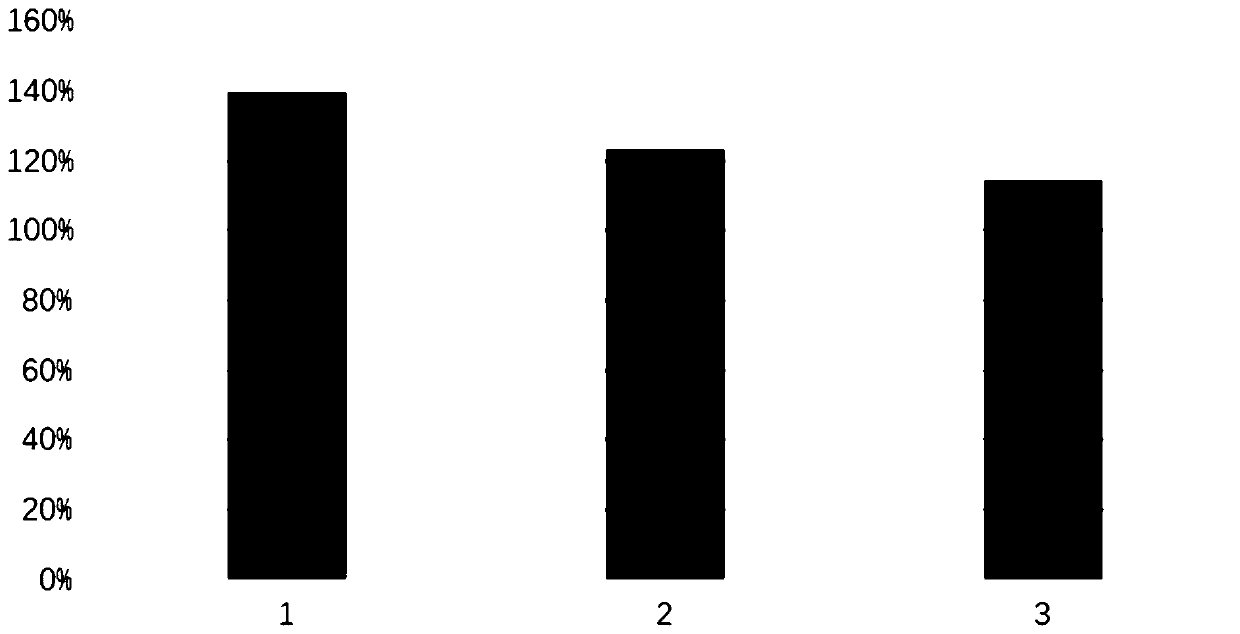

Embodiment 1

[0044] A lipase composition, the lipase composition is composed of the following components in mass percentage: 75% of lipase from Pseudomonas aeruginosa, 25% of lipase from Thermomyces lanuginosa.

[0045] A kind of preparation method of fatty acid methyl ester, it is to use lipase composition as above to prepare fatty acid methyl ester, concrete steps are as follows:

[0046] 1) Take kitchen waste oil and put it in a triangular flask, add 240-560ppm lye NaOH to adjust the pH to 5-6, shake well in a shaker at a temperature of 30°C for later use;

[0047] 2) Take a lipase composition with a mass ratio of 0.3% and add it into purified water, mix evenly, then add it to the soybean oil deodorized distillate in step 1), and place it in a shaking table for reaction;

[0048] 3) Add 1.5 equivalents of methanol several times 3 hours before the reaction, centrifuge at a speed of 300r / min for 24 hours, add 0.25 equivalents of methanol at 0 hours, add 0.25 equivalents of methanol at 1 h...

Embodiment 2

[0050] A lipase composition, the lipase composition is composed of the following components in terms of protein mass percentage: 50% of lipase from Pseudomonas aeruginosa, 50% of lipase from Thermomyces lanuginosa.

[0051] A kind of preparation method of fatty acid methyl ester, it is to use lipase composition as above to prepare fatty acid methyl ester, concrete steps are as follows:

[0052] 1) Take the deodorized distillate of soybean oil and place it in a reaction kettle with a volume of 6 cubic meters and add 200-300ppm of lye NaOH to adjust the pH to 5-6. spare;

[0053] 2) Take a lipase composition with a mass ratio of 0.2% and add it to tap water, mix evenly, then add it to the soybean oil deodorization distillate in step 1), adjust the moisture content of the entire reaction system to 3%, and place it in a reaction kettle reaction;

[0054] 3) 1.5 equivalents of methanol was added during the reaction for 8 hours, and the reaction was centrifuged at a speed of 50 r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com