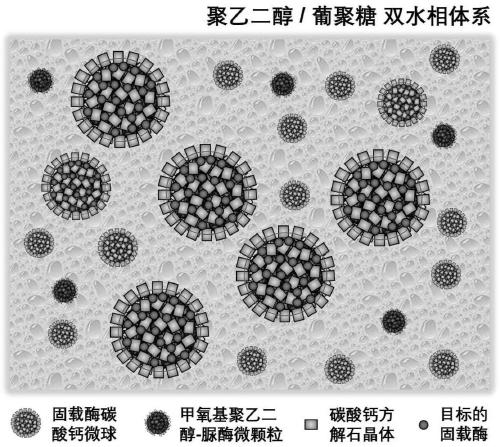

Method for immobilizing enzymes based on biomimetic mineralization process of two-aqueous-phase system

A two-phase system, biomimetic mineralization technology, applied in the direction of fixing on or in the inorganic carrier, fixing on/in the organic carrier, etc., can solve the problems of enzyme shedding and low encapsulation efficiency, and achieve easy Recycling, high encapsulation rate, good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

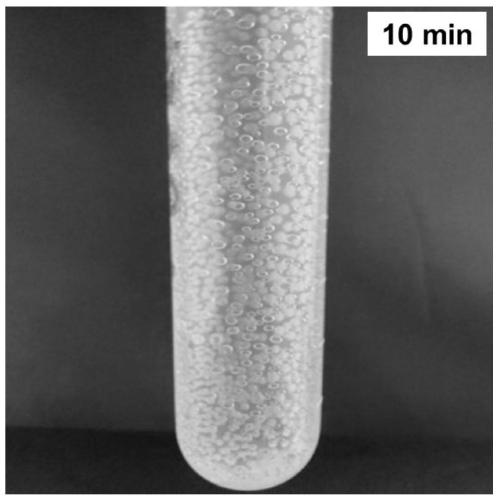

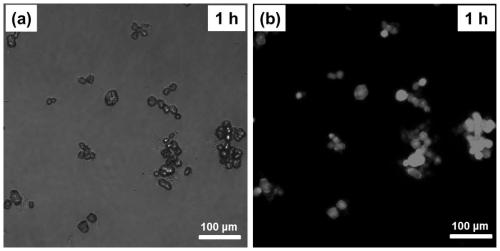

Examples

Embodiment 1

[0045]A method for immobilizing enzymes based on a two-phase system biomimetic mineralization process, comprising the following steps:

[0046] Step 1: Methoxypolyethylene glycol-urease copolymer particles

[0047] Weigh 16 mg of methoxypolyethylene glycol acetaldehyde with a molecular weight of 5 kDa, weigh 16 mg of urease with a molecular weight of 540 kDa and place them in a screw bottle; add 1 mL of deionized water (pH=5) to form a mixture aqueous solution The aqueous solution of the mixture was left to react for 100 hours, and dried in a vacuum dryer (DZF-6050, Shanghai Yiheng Scientific Instrument Co., Ltd.) at a pressure of less than 0.01 MPa to form methoxypolyethylene glycol-urease copolymer particles.

[0048] Step 2: Aqueous two-phase system containing the target enzyme

[0049] Prepare 10mmol / L Tris-HCl buffer solution with a pH of 7.4; weigh 10mg of catalase with a molecular weight of 250kDa, add it to 6.68mL Tris-HCl buffer solution, and dissolve it completely t...

Embodiment 2

[0060] A method for immobilizing enzymes based on a two-phase system biomimetic mineralization process, comprising the following steps:

[0061] Step 1: Methoxypolyethylene glycol-urease copolymer particles

[0062] Weigh 16 mg of methoxypolyethylene glycol acetaldehyde with a molecular weight of 5 kDa, weigh 16 mg of urease with a molecular weight of 540 kDa, and place them in a screw bottle; add 1 mL of deionized water (pH=5) to form a mixture Aqueous solution; the aqueous solution of the mixture was left to react for 100 hours, and dried in a vacuum dryer (DZF-6050, Shanghai Yiheng Scientific Instrument Co., Ltd.) at a pressure of less than 0.01MPa to form methoxypolyethylene glycol-urease copolymer particles.

[0063] Step 2: Aqueous two-phase system containing the target enzyme

[0064] Prepare 10mmol / L Tris-HCl buffer solution with a pH of 7.4; weigh 100mg of catalase with a molecular weight of 250kDa; dissolve it in 10mL Tris-HCl buffer solution and dissolve completely...

Embodiment 3

[0073] A method for immobilizing enzymes based on a two-phase system biomimetic mineralization process, comprising the following steps:

[0074] Step 1: Methoxypolyethylene glycol-urease copolymer particles

[0075] Weigh 16 mg of methoxypolyethylene glycol acetaldehyde with a molecular weight of 5 kDa, weigh 16 mg of urease with a molecular weight of 540 kDa and place them in a screw bottle; add 1 mL of deionized water (pH=5) to form a mixture aqueous solution The aqueous solution of the mixture was left to react for 100 hours, and dried in a vacuum dryer (DZF-6050, Shanghai Yiheng Scientific Instrument Co., Ltd.) at a pressure of less than 0.01 MPa to form methoxypolyethylene glycol-urease copolymer particles.

[0076] Step 2: Aqueous two-phase system containing the target enzyme

[0077] Prepare 10mmol / L Tris-HCl buffer solution with a pH of 7.4; weigh 10mg of catalase with a molecular weight of 250kDa, add it to 6.68mL Tris-HCl buffer solution, and dissolve it completely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com