Method for rapid enzymolysis and quantitative enzyme recovery of straws

A technology of enzymatic hydrolysis and straw, applied in the direction of biofuel, fermentation, etc., can solve the problems of high cost, short life, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

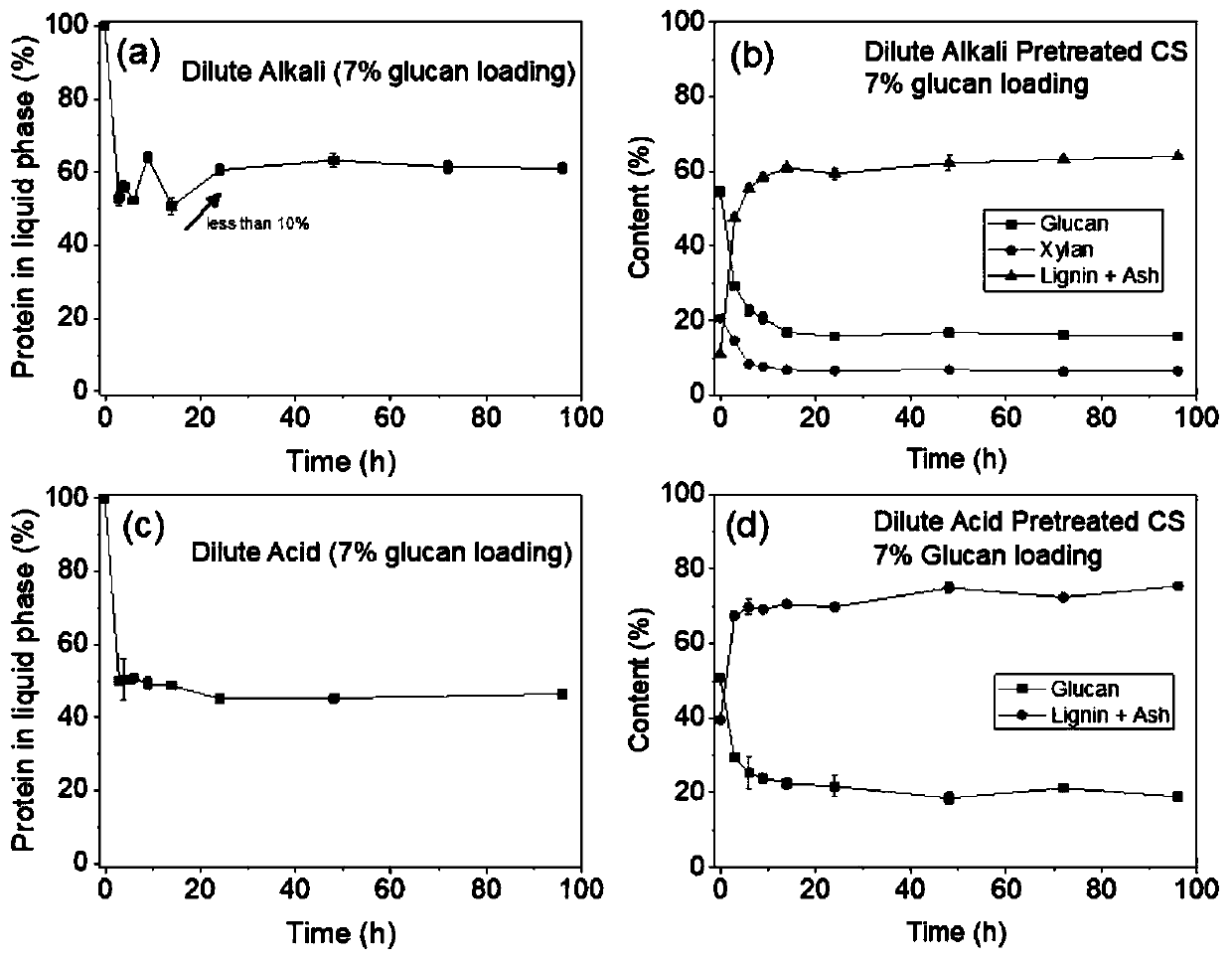

[0024] Dilute alkali and dilute acid pretreatment were carried out on corn stover under optimal conditions to study the effect of pretreatment on enzyme hydrolysis and enzyme adsorption. Dilute acid pretreatment removed xylan from corn stover, while the content of glucan and lignin (containing ash) increased to 50.8% and 40.1%, respectively. Relative to dilute acid pretreatment, dilute alkaline pretreated corn stover had similar glucan content (54.6%), higher xylan content (21.8%), and much lower lignin content (10.9%) .

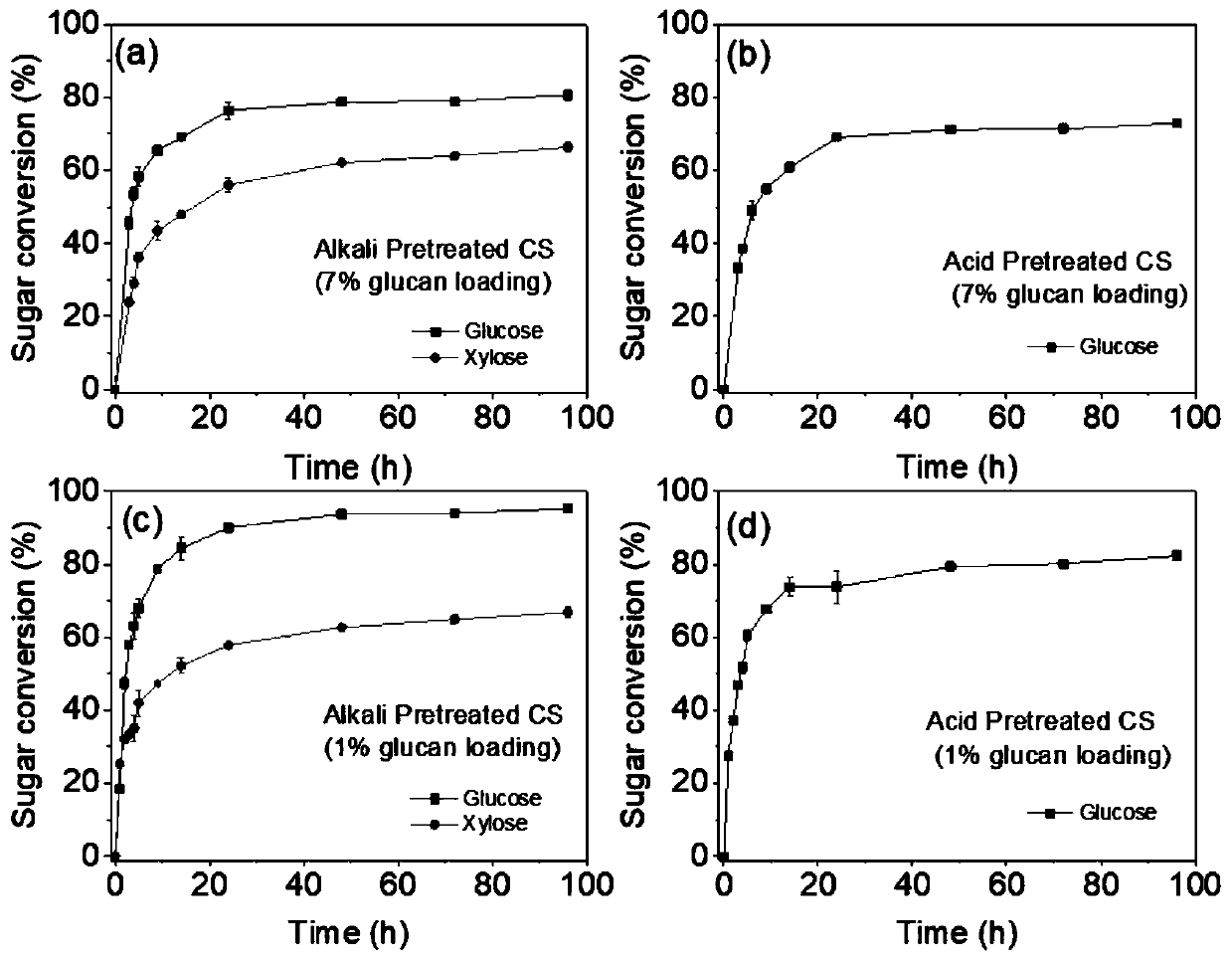

[0025] The difference in composition of corn stover pretreated by dilute alkali and dilute acid will affect its enzymatic hydrolysis and enzyme adsorption. Such as figure 1 It was shown that for dilute alkaline pretreated corn stover, at 7% (w / w) dextran concentration, dextran and xylan were rapidly converted to glucose and xylose in the initial stage of enzymatic hydrolysis, and hydrolyzed after 24 hours The rate starts to drop. At 24 hours, the concent...

Embodiment 2

[0029] According to 1000g reaction system (sulfuric acid content 1%, corn stalk dry weight content 10%), dilute acid was used to pretreat 500g (dry weight) corn stalks for subsequent enzymatic hydrolysis and enzyme recovery experiments.

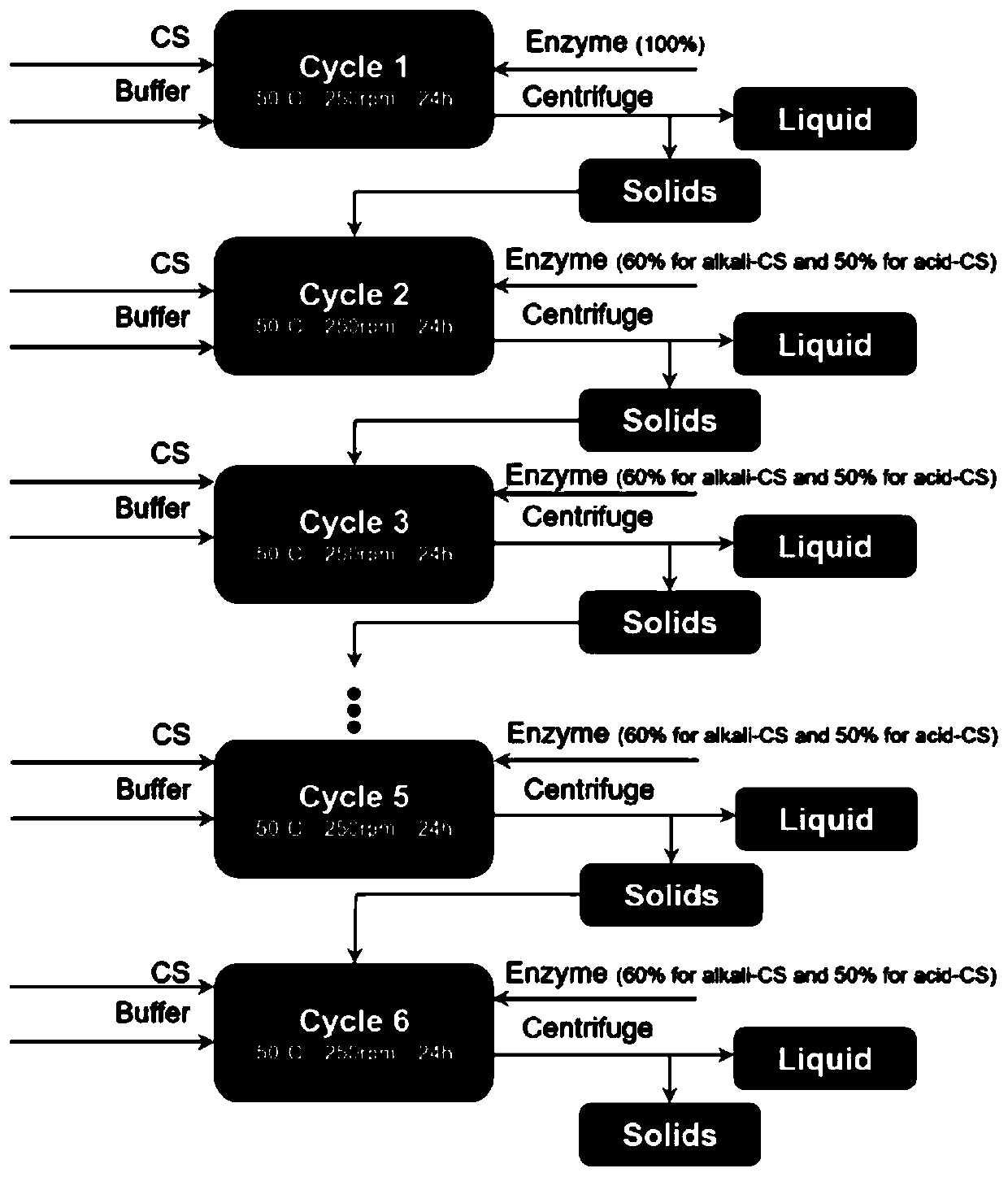

[0030] The enzymatic hydrolysis was carried out according to 100g reaction system (22% substrate concentration), three groups were paralleled, and four rounds of experiments were carried out. In the first round of experiments, the enzyme dosage was calculated according to the dextran content, and its composition was: 3.08mL of cellulase and 3.2mL of xylanase in each group. The pH was adjusted to 4.8, and all were placed in a shaker at 50°C and 250 rpm for enzymatic hydrolysis. The experiment adopts batch feeding, that is, corn stalks with 11% substrate concentration are added first, and another corn stalk with 11% substrate concentration is added after hydrolysis for 2 hours.

[0031] After 24 hours of hydrolysis, all three shake flasks were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com