Method for preparing active peptide through euphausia superba powder

A technology of Antarctic krill powder and active peptides, which is applied in the field of active peptide preparation, can solve the problems of low yield of small molecule active peptides, achieve the effect of maintaining the function of active peptides, increasing the yield, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

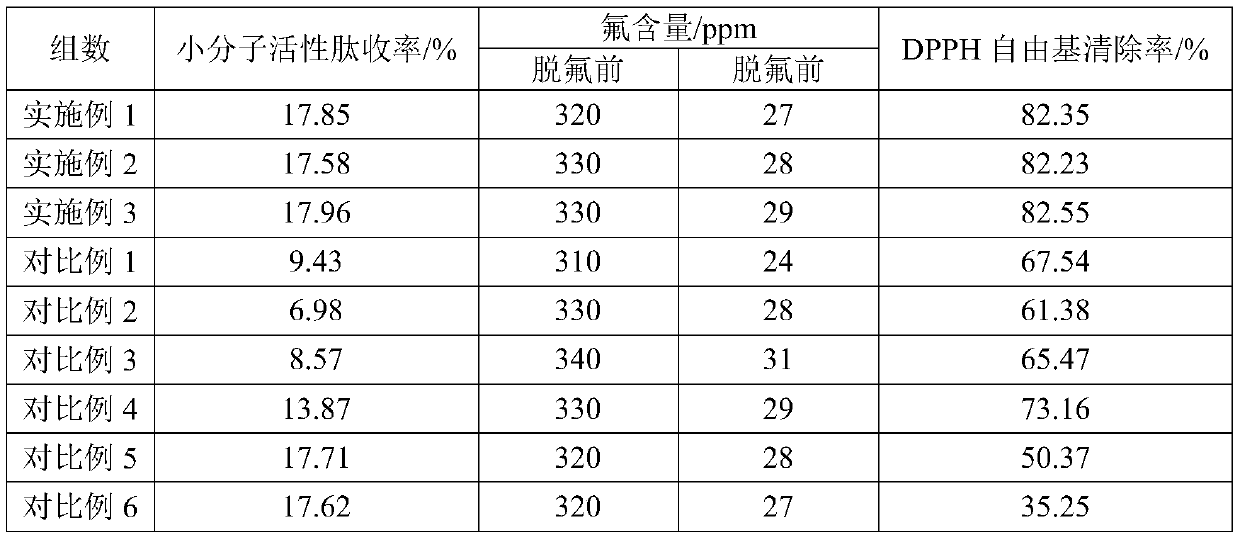

Examples

Embodiment 1

[0036] A method for preparing active peptides using Antarctic krill powder, comprising the following steps:

[0037] (1) defatted Antarctic krill powder and water are mixed in a ratio of 1:3 to obtain homogenate liquid I;

[0038] (2) Use 2M phosphoric acid solution to adjust the pH of homogenate I to 3.2, add pepsin after preheating to 42°C, the concentration of pepsin in homogenate I is 600U / g, and enzymolyze it at 42°C for 3 hours Liquid II;

[0039] (3) Use 2M sodium hydroxide solution to adjust the pH of the enzymolysis solution II to 7.2, add trypsin, the concentration of trypsin in the enzymolysis solution II is 50U / g, and obtain the enzymolysis solution after enzymolysis at 47°C for 3 hours III;

[0040] (4) Add flavor protease to enzymolysis solution III, the concentration of flavor protease in enzymolysis solution III is 150U / g, and enzymolysis solution IV is obtained after enzymolysis at 47° C. for 1 hour;

[0041] (5) Inactivate the enzyme solution IV at 92°C for ...

Embodiment 2

[0046] A method for preparing active peptides using Antarctic krill powder, comprising the following steps:

[0047] (1) The defatted Antarctic krill powder and water are mixed with a mass ratio of 1:2.5 to obtain homogenate I;

[0048] (2) Use a 2.5M phosphoric acid solution to adjust the pH of homogenate I to 3.5, add papain after preheating to 45°C, the concentration of papain in homogenate I is 500U / g, and obtain after enzymatic hydrolysis at 45°C for 2.5h Enzyme solution II;

[0049] (3) Use a 2.5M sodium hydroxide solution to adjust the pH of the enzymolysis solution II to 7.5, add trypsin, the concentration of trypsin in the enzymolysis solution II is 80U / g, and obtain the enzyme after enzymolysis at 50°C for 2.5h Solution III;

[0050] (4) Add flavor protease to enzymolysis solution III, the concentration of flavor protease in enzymolysis solution III is 220U / g, enzymolysis at 50°C for 1.5h to obtain enzymolysis solution IV;

[0051] (5) Inactivate the enzyme soluti...

Embodiment 3

[0056] A method for preparing active peptides using Antarctic krill powder, comprising the following steps:

[0057] (1) defatted Antarctic krill powder and water are mixed in a ratio of 1:2 to obtain homogenate liquid I;

[0058] (2) Adjust the pH of the homogenate I to 3.0 with a 1.5M phosphoric acid solution, add pepsin after preheating to 40°C, the concentration of pepsin in the homogenate I is 700U / g, and obtain the enzyme after enzymatic hydrolysis at 40°C for 2 hours Solution II;

[0059] (3) Use a 1.5M sodium hydroxide solution to adjust the pH of the enzymolysis solution II to 7.0, add trypsin, the concentration of trypsin in the enzymolysis solution II is 80U / g, and enzymolyze at 45°C for 2 hours to obtain enzymolysis Liquid III;

[0060] (4) Add flavor protease to enzymolysis solution III, the concentration of flavor protease in enzymolysis solution III is 220U / g, enzymolysis at 45°C for 2 hours to obtain enzymolysis solution IV;

[0061] (5) Inactivate the enzym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com