Modified polyester fiber and preparation method

A technology of modified polyester and fiber, which is applied in the field of modified polyester fiber and its preparation, which can solve the problems of fiber performance degradation and obstruction, and achieve the effect of improved washability and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

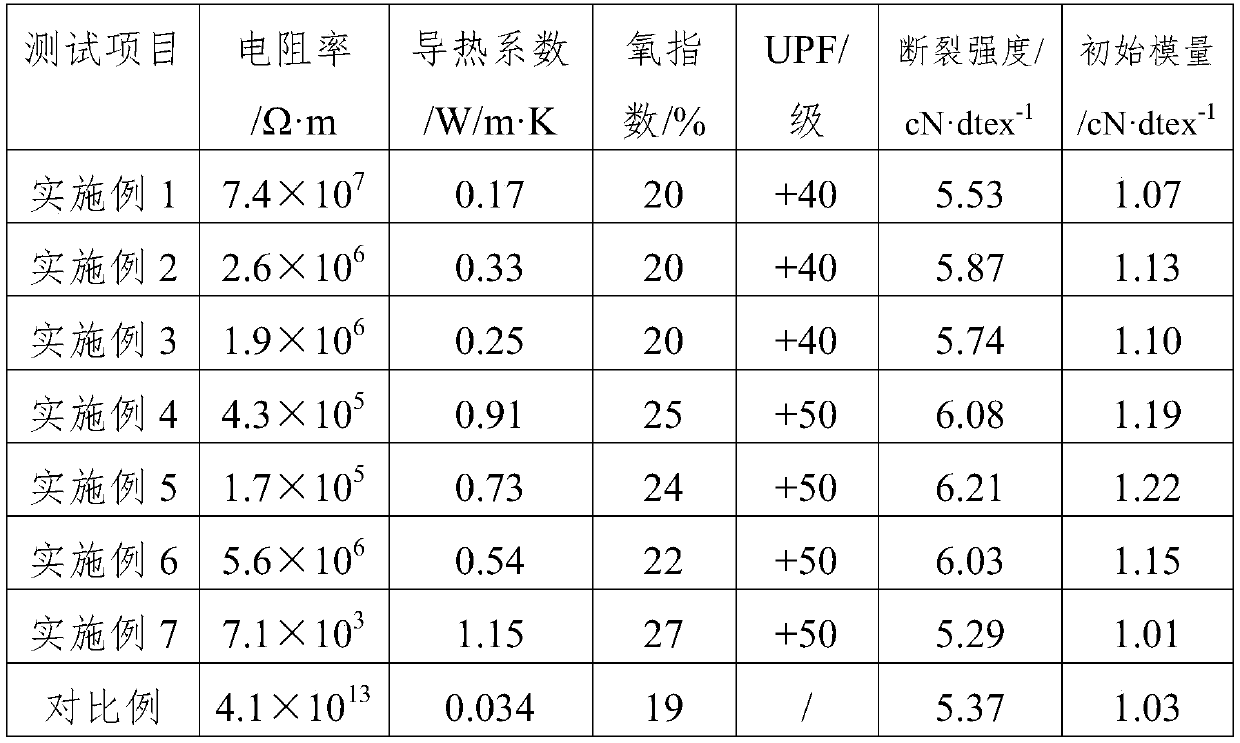

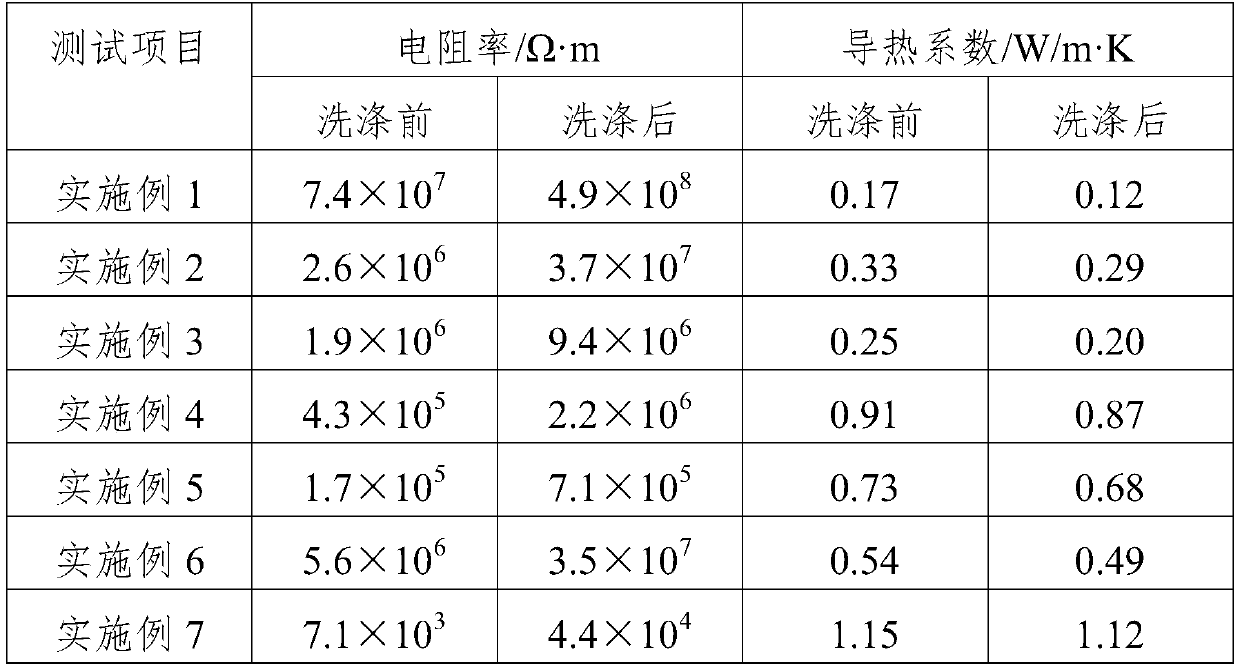

Examples

Embodiment 1

[0045] 1 part of polyester / graphene / POSS particle 1 and 99 parts of polyester chip were melt-spun to obtain modified polyester fiber 1. Melt spinning process: melt spinning temperature is 275°C, side blowing cooling process is adopted, blowing temperature is 18°C, blowing speed is 0.4m / s, winding process is carried out at a winding speed of 3000m / s, stretching, twisting, Heat setting, oiling, and winding molding to obtain modified polyester fiber 1.

Embodiment 2

[0047] 10 parts of polyester / graphene / POSS particles 2 and 90 parts of polyester chips were melt-spun to obtain modified polyester fiber 2. The melt spinning process is consistent with that in Example 1.

Embodiment 3

[0049] 20 parts of polyester / graphene / POSS particles 3 and 80 parts of polyester chips were melt-spun to obtain modified polyester fiber 3. The melt spinning process is consistent with that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com