A vacuum gauge and its working method

A vacuum gauge and tungsten trioxide technology, applied in vacuum gauges, instruments, measuring devices, etc., can solve the problems of high electric field or magnetic field applied by vacuum ionization gauges, complex structure, large volume, etc., and meet the requirements of low test conditions and volume. Small, configurable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

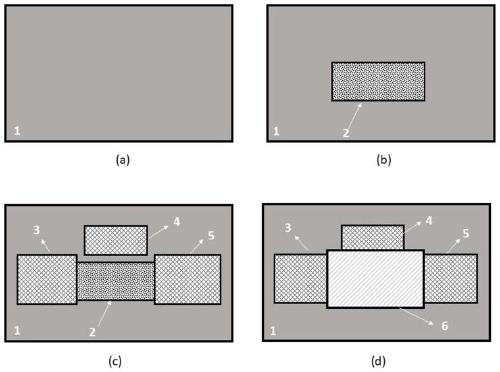

[0034] A preparation of a vacuum gauge and a working method thereof, comprising the following steps:

[0035] Step 1: Choose flexible natural mica as the substrate. Use blades or ultrasonic methods to obtain mica flakes with a surface roughness below 1 nm.

[0036] Step 2: Put a metal mask on the mica sheet, and use laser deposition technology to deposit a rectangular WO on the hollow mask. 3 ditch. The parameters used in the laser deposition process are: substrate temperature 500 °C, laser wavelength 248 nm, laser energy 1.2 J cm -2 , pulse frequency 5 Hz, oxygen bias 13 Pa, WO 3 The film thickness is 100 nm.

[0037] Step 3: Align the metal mask plate with the electrode shape hollowed out to the channel, and use thermal evaporation technology to vapor-deposit Cr / Au metal electrodes with a thickness of 110 nm as the gate, source and drain.

[0038] Step 4: Cut a piece of the prepared ion gel and stick it on the channel and the electrode with a thickness of 500 µm.

[00...

Embodiment 2

[0041] A preparation of a vacuum gauge and a working method thereof, comprising the following steps:

[0042] Step 1: Choose flexible natural mica as the substrate. Use blades or ultrasonic methods to obtain mica flakes with a surface roughness below 1 nm.

[0043] Step 2: Put a metal mask on the mica sheet, and use laser deposition technology to deposit a rectangular WO on the hollow mask. 3 ditch. The parameters used in the laser deposition process are: substrate temperature 500 °C, laser wavelength 248 nm, laser energy 1.2 J cm -2 , pulse frequency 5 Hz, oxygen bias 13 Pa, WO 3 The film thickness is 100 nm.

[0044]Step 3: Align the metal mask with the electrode shape hollowed out to the channel, and use magnetron sputtering technology to vapor-deposit ITO transparent electrodes with a thickness of 110 nm as the gate, source and drain.

[0045] Step 4: Cut a piece of the prepared ion gel and stick it on the channel and the electrode with a thickness of 500 µm.

[0046...

Embodiment 3

[0048] A preparation of a vacuum gauge and a working method thereof, comprising the following steps:

[0049] Step 1: Select Rigid Substrate SiO 2 / Si as the substrate. Use acetone and ethanol to ultrasonically clean for 5 minutes to ensure the surface is clean.

[0050] Step 2: On SiO 2 A metal mask is placed on the / Si substrate, and a rectangular WO is deposited on the hollow mask using laser deposition technology. 3 ditch. The parameters used in the laser deposition process are: substrate temperature 500 °C, laser wavelength 248 nm, laser energy 1.2 J cm -2 , pulse frequency 5 Hz, oxygen bias 13 Pa, WO 3 The film thickness was 100 nm.

[0051] Step 3: Align the metal mask with the electrode shape hollowed out to the channel, and use magnetron sputtering technology to vapor-deposit ITO transparent electrodes with a thickness of 110 nm as the gate, source and drain.

[0052] Step 4: Cut a piece of the prepared ion gel and stick it on the channel and the electrode with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com