Superfine fragrant peanut oil product with low pollutant content and preparation method thereof

A technology of peanut oil and aroma, which is applied in the field of oils and fats, and can solve problems such as unfavorable production of pressed peanut oil with aroma, inapplicability of pressed peanut oil with aroma, bad flavor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

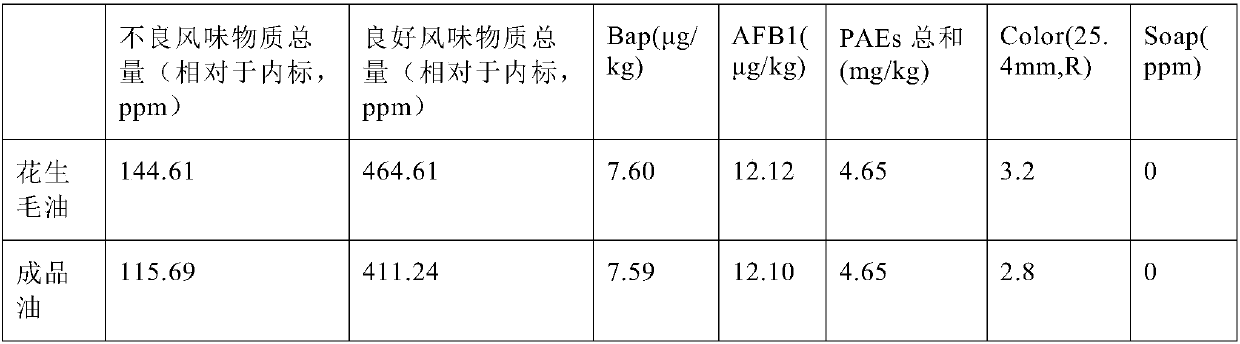

Embodiment 1

[0091] Add 1000ppm potassium iodide and activated carbon A to peanut crude oil with a water content of 0.2%, the pH=10.98, and then contact at 60°C for 2h. Afterwards, the temperature was gradually lowered to 18°C under the heat exchange of the tubular heat exchanger, and the crystallization was stirred at a low speed (stirring speed 12 rpm) while the temperature was lowered, and the whole cooling plus crystallization time was controlled for 4 hours. After the crystal growth is completed, the semi-finished oil is obtained by filtering through a plate and frame filter. Then add peanut powder to the semi-product oil, continue to stir at 18°C at low speed (stirring speed 12rpm) for crystal growth for 4 hours, after the crystal growth is completed, filter through a plate and frame filter to obtain refined oil. Wherein the weight ratio of peanut powder and activated carbon is 10:1, and the total weight of the two is 1.1% of the oil weight. The various indicators of refined oil...

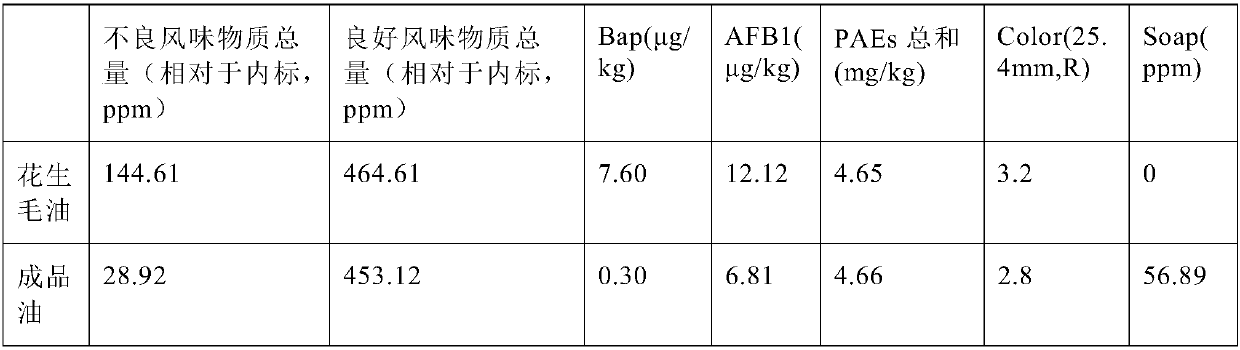

Embodiment 2

[0096] Add 5000ppm potassium iodide and activated carbon C to the peanut crude oil with a water content of 0.2%, the pH=11.30, and then contact at 70°C for 2h. Afterwards, the temperature was gradually lowered to 15° C. under the heat exchange of a tubular heat exchanger, and the crystallization was stirred at a low speed (stirring speed 20 rpm) while the temperature was lowered. The whole cooling plus crystallization time was controlled for 6 hours. After the crystal growth is completed, the semi-finished oil is obtained by filtering through a plate and frame filter. Then add peanut powder to the semi-product oil, continue to stir at 15°C at a low speed (stirring speed 20rpm) to grow crystals for 6 hours, and filter through a filter to obtain refined oil after the crystal growth is completed. Wherein the weight ratio of peanut powder and activated carbon is 10:1, and the total weight of the two is 2.2% of the oil weight. The various indicators of refined oil were tested, and...

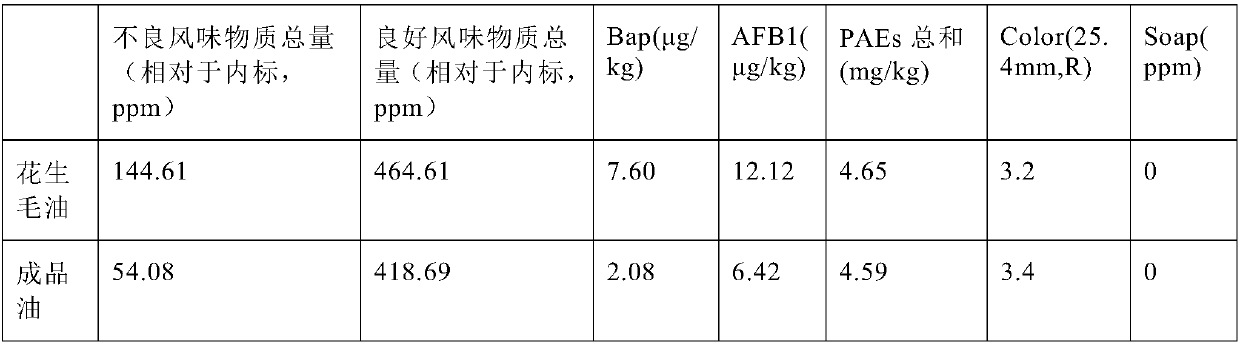

Embodiment 3

[0101] Add 1000ppm potassium bromide and activated carbon D to the peanut crude oil with a water content of 0.2%, the pH=10.15, and then contact at 40°C for 2h. Afterwards, the temperature was gradually lowered to 20° C. under the heat exchange of a tubular heat exchanger, and the crystallization was stirred at a low speed (stirring speed 25 rpm) while the temperature was lowered, and the whole cooling plus crystallization time was controlled for 2 hours. After the crystal growth is completed, the semi-finished oil is obtained by filtering through a plate and frame filter. Then add peanut powder to the semi-product oil, continue to stir at 20°C at a low speed (stirring speed 25rpm) to grow crystals for 2 hours, after the crystal growth is completed, filter through a plate and frame filter to obtain refined oil. Wherein the weight ratio of peanut powder and activated carbon is 30:1, and the total weight of the two is 3.0% of the oil weight. The various indicators of refined oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com