Surface treatment method of continuous casting blank

A technology of surface treatment and continuous casting billet, applied in the field of surface treatment of continuous casting billet, can solve the problems of uneven cooling, uncontrollable cooling speed of billet surface, and billet bending, and achieve the effect of low energy consumption production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

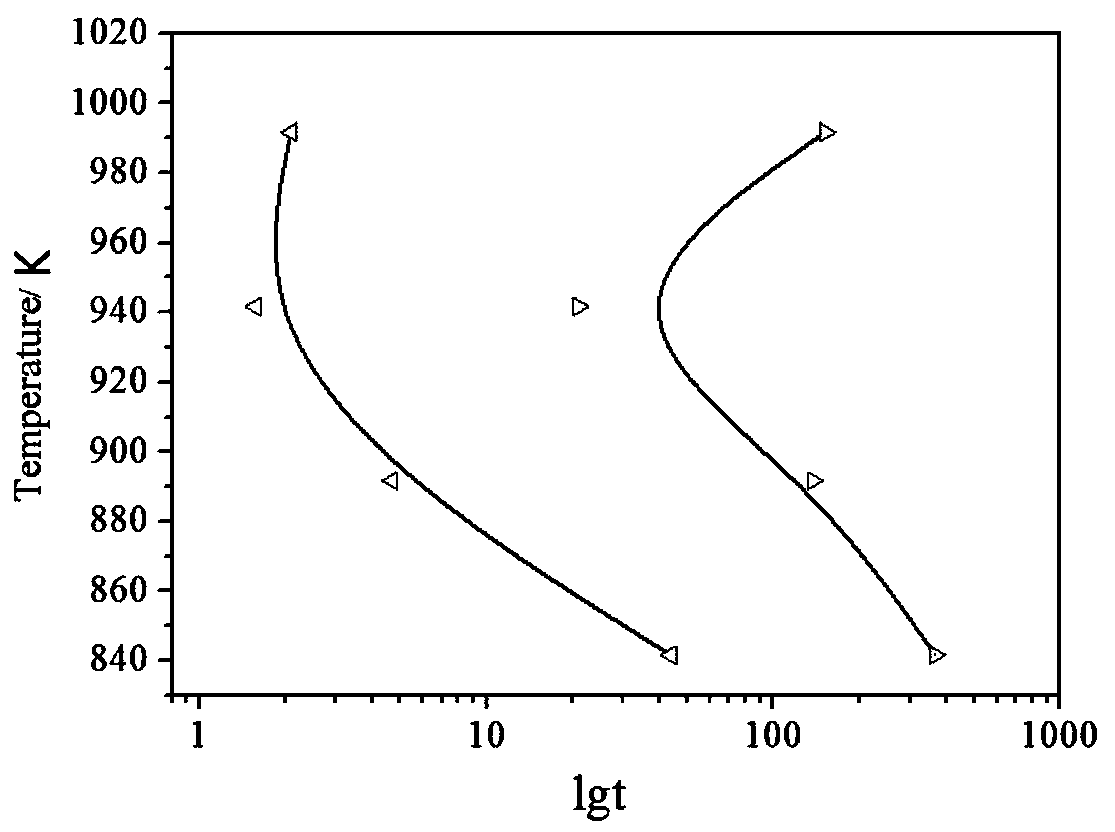

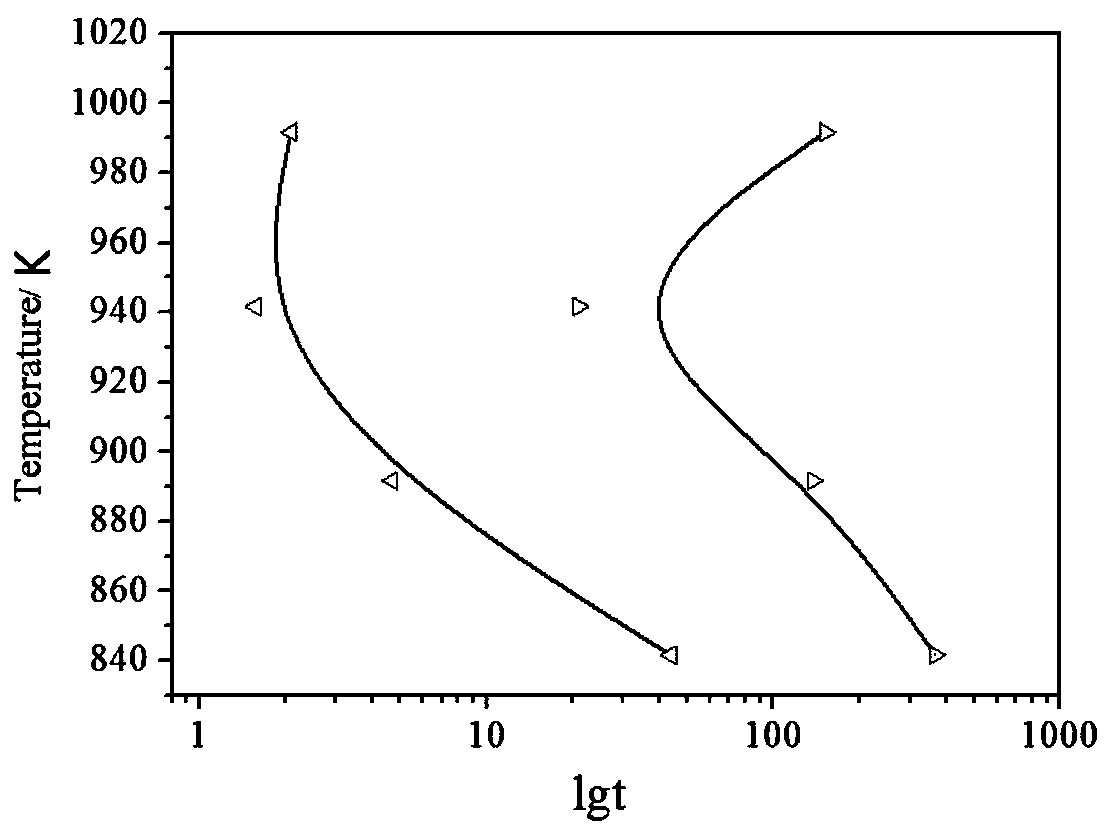

Image

Examples

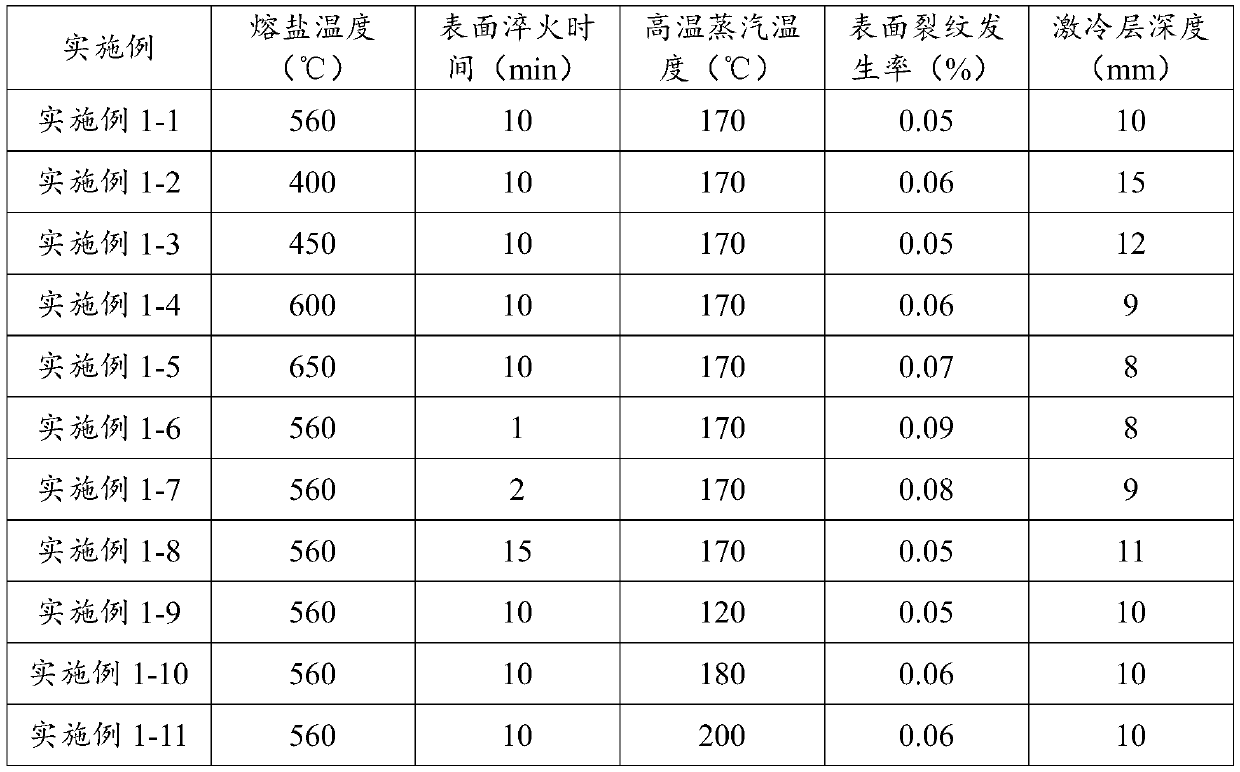

Embodiment 1

[0057] The method of the present invention is used in the production of high-end automotive panels in slab continuous casting workshops, including a cooling process with the following steps:

[0058] (1) After flame cutting and cut-to-length cutting of the continuous casting slab, the cut continuous casting slab is transported to the molten salt tank for quenching to realize rapid cooling of the continuous casting slab surface. Among them, the temperature at which the continuous casting slab enters the molten salt tank is 1050°C, the temperature of the molten salt is 560°C, and the viscosity of the molten salt is 3.7cp. The molten salt is a mixed molten salt of carbonate, wherein the mass ratio of potassium carbonate, sodium carbonate and lithium carbonate is 1:1:1. The residence time of the continuous casting slab in the molten salt tank, that is, the surface quenching time is 10 minutes.

[0059] (2) After the quenched continuous casting slab is exported to the molten salt ...

Embodiment 2

[0067] The method of the present invention is used in the production of high-end cold heading steel in the continuous casting billet workshop, including the cooling process with the following steps:

[0068](1) After flame cutting and cut-to-length cutting of the continuous casting billet, the cut continuous casting billet is transported to the molten salt tank for quenching to realize rapid cooling of the continuous casting billet surface. Among them, the size of the billet is 160×160mm, the temperature of the continuous casting billet entering the molten salt tank is 900°C, the temperature of the molten salt is 450°C, and the viscosity of the molten salt is 1.5cp. The molten salt is a mixed molten salt of nitrate, wherein the mass ratio of sodium nitrate, potassium nitrate and calcium nitrate is 4:3:1. The residence time of the continuous casting billet in the molten salt tank, that is, the surface quenching time is 3 minutes.

[0069] (2) After the quenched continuous cast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com