3D-printed bone tissue engineering scaffold with sustained-release antibacterial function and preparation method of scaffold

A technology of bone tissue engineering and 3D printing, applied in the fields of additive processing, medical science, prosthesis, etc., can solve the problems of weakened differentiation ability, large side effects, poor drug absorption effect, etc., to achieve enhanced biological activity, good biological activity, The effect of good bone repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing a 3D printing bone tissue engineering scaffold material with a slow-release antibacterial function, comprising the following steps:

[0038] a) dissolving sodium alginate in deionized water to prepare a sodium alginate solution with a mass fraction of 6%;

[0039] b) dissolving berberine in dimethyl sulfoxide to obtain a 0.1 g / ml berberine-dimethyl sulfoxide solution;

[0040] c) According to the ratio of berberine to sodium alginate mass ratio of 0.02~0.2:6, the berberine-dimethyl sulfoxide solution obtained in step b) is added dropwise to the 6% sodium alginate solution obtained in step a), so that The two are mixed evenly to obtain a mixed solution;

[0041] d) Put the mixed solution obtained in step c) at 50-60°C for 30-60 minutes, and then slowly add calcium phosphate to the sodium alginate after the heat preservation according to the mass ratio of calcium phosphate and sodium alginate of 10:3 and berberine mixed solution, uniformly dispers...

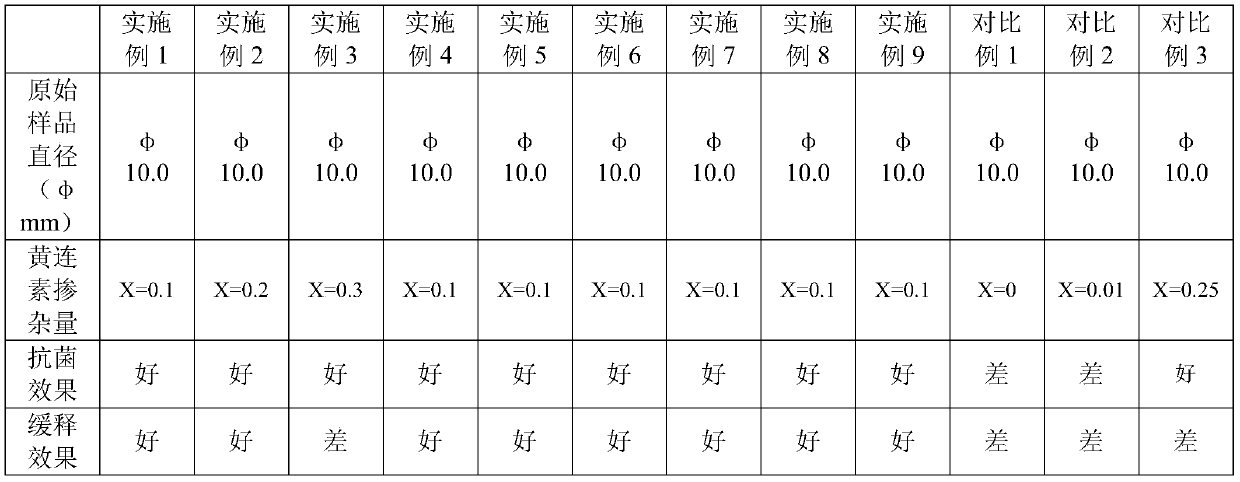

Embodiment 1

[0053] In a water bath at 30°C, add sodium alginate powder material to deionized water to prepare a 6% sodium alginate solution, add 1ml of berberine-dimethyl sulfoxide solution with a concentration of 0.1g / ml, and use a magnetic stirrer Mix it well until smooth. After preheating at 50°C for 30 to 60 minutes, the viscosity of the sodium alginate solution is reduced, and then the solid hydroxyapatite powder is slowly added to the preheated solution, and the slurry is mixed evenly with a homogeneous stirrer until no observation is observed. When the agglomeration of hydroxyapatite occurs, the mass ratio of hydroxyapatite, sodium alginate, berberine and deionized water in the final slurry is 20:6:0.1:100, and this mixed slurry is used as 3D printing ink Materials, prepare 30% calcium chloride solution as cross-linking agent. Using 3D inkjet printing technology, the mixed ink is printed into a calcium phosphate scaffold with a first-level macroporous structure, and then the scaff...

Embodiment 2

[0055] According to the method of Example 1, first prepare 3D printing ink, carry out 3D printing of first-level macro-scale macroporous design to prepare scaffolds, then immerse in calcium chloride solution for cross-linking, and then perform freeze-drying treatment, the remaining parameters selection and preparation process and implementation The same as Example 1, the difference is that in this example, the 3D printing ink used in Example 1, the mass ratio of hydroxyapatite, sodium alginate, berberine and deionized water is adjusted to 20: 6: 0.2: 100, made into slurry as 3D printing ink; 30% calcium chloride solution as cross-linking agent. All the other processing methods are the same as those described in Example 1. Compared with Example 1, because the solid content of berberine in the printing slurry is more in this example, the total amount of drug-loaded bone tissue engineering scaffold with slow-release antibacterial function is more, so the scaffold obtained in this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com