Hollow-nanostructural Co2P@C composite material as well as preparation method and application thereof

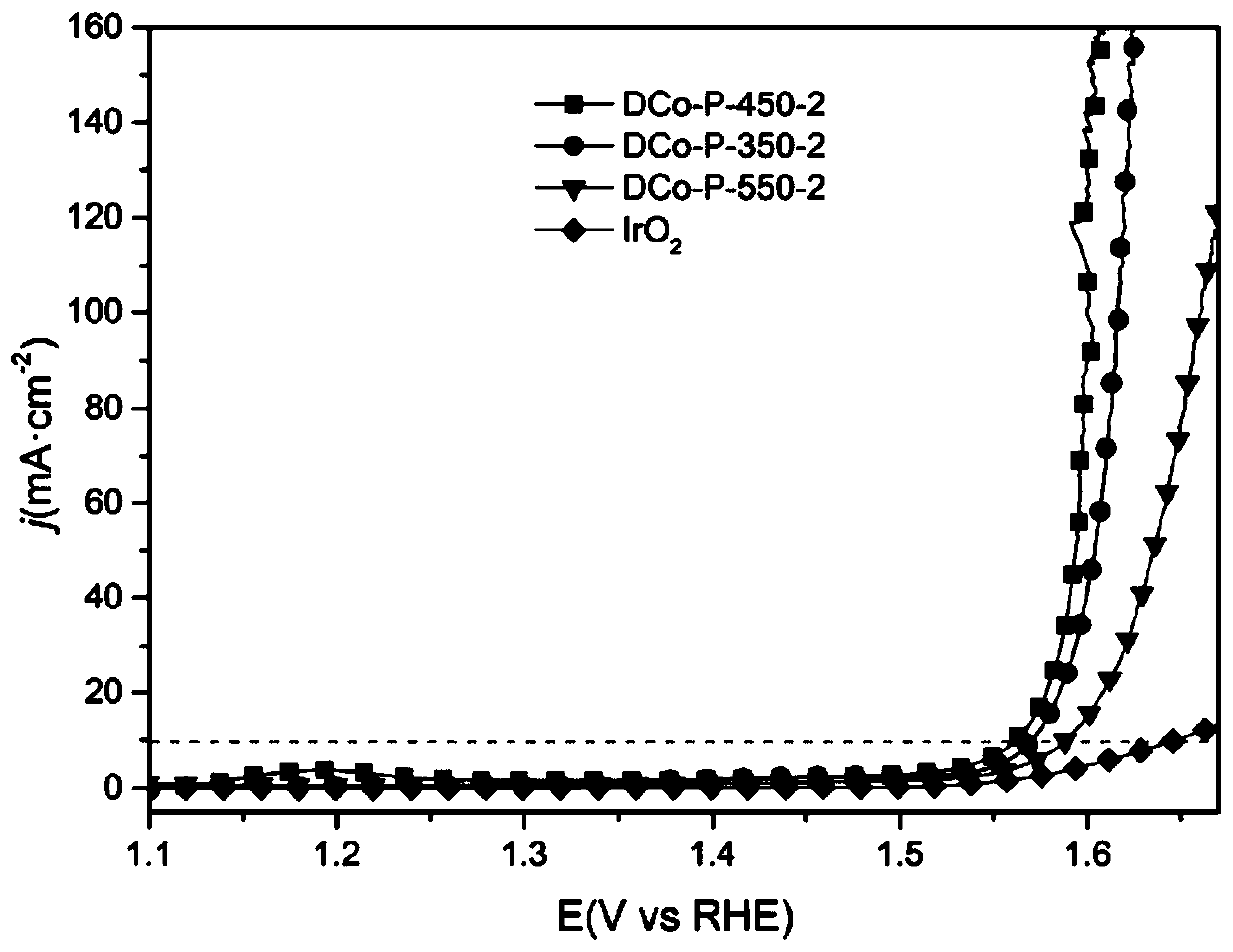

A nanostructure and composite material technology, applied in the field of metal organic framework materials, nanomaterials, and nanocatalysis, can solve the problems that the OER performance of Co-based phosphides needs to be further improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

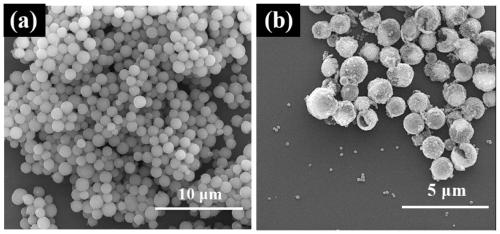

[0027] (1) Preparation of precursor Co-BTC

[0028] (a) Cobalt nitrate hexahydrate Co(NO 3 ) 2 ·6H 2 O (0.72mmol, 0.21g) was dissolved in the mixed solvent of 30ml ethylene glycol and 20ml ethanol, stirred until forming a red transparent solution;

[0029] (b) Add 0.2g of polyvinylpyrrolidone PVP to the solution obtained in (a), and stir until completely dissolved;

[0030] (c) Trimellitic acid H 3 BTC (0.34mmol, 0.07g) was added to the solution obtained in (b), ultrasonicated for 10 minutes, stirred evenly, put into the reaction kettle, kept at 150°C for 24h, and then naturally cooled to room temperature;

[0031] (d) Collect the product by centrifugation, wash the product three times with ethanol, and then dry it in a vacuum oven at 60°C for 12 hours to obtain the precursor Co-BTC;

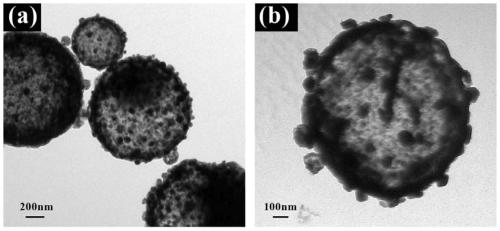

[0032] (2) Preparation of Co with hollow nanostructure 2 P@C composite materials:

[0033] The Co-BTC material prepared by 0.1g step (1) and 1g sodium hypophosphite NaH 2 PO 2 Put them in...

Embodiment 2

[0037] (1) Preparation of precursor Co-BTC

[0038] (a) Cobalt nitrate hexahydrate Co(NO 3 ) 2 ·6H 2 O (0.72mmol, 0.21g) was dissolved in the mixed solvent of 30ml ethylene glycol and 20ml ethanol, stirred until forming a red transparent solution;

[0039] (b) Add 0.2g of polyvinylpyrrolidone PVP to the solution obtained in (a), and stir until completely dissolved;

[0040] (c) Trimellitic acid H 3 BTC (0.34mmol, 0.07g) was added to the solution obtained in (b), ultrasonicated for 10 minutes, stirred evenly, put into the reaction kettle, kept at 150°C for 24h, and then naturally cooled to room temperature;

[0041] (d) Collect the product by centrifugation, wash the product three times with ethanol, and then dry it in a vacuum oven at 60°C for 12 hours to obtain the precursor Co-BTC;

[0042] (2) Preparation of Co with hollow nanostructure 2 P@C composite materials:

[0043] The Co-BTC material prepared by 0.1g step (1) and 1g sodium hypophosphite NaH 2 PO 2 Put them ...

Embodiment 3

[0046] (1) Preparation of precursor Co-BTC

[0047] (a) Cobalt nitrate hexahydrate Co(NO 3 ) 2 ·6H 2 O (0.72mmol, 0.21g) was dissolved in the mixed solvent of 30ml ethylene glycol and 20ml ethanol, stirred until forming a red transparent solution;

[0048] (b) Add 0.2g of polyvinylpyrrolidone PVP to the solution obtained in (a), and stir until completely dissolved;

[0049] (c) Trimellitic acid H 3 BTC (0.34mmol, 0.07g) was added to the solution obtained in (b), ultrasonicated for 10 minutes, stirred evenly, put into the reaction kettle, kept at 150°C for 24h, and then naturally cooled to room temperature;

[0050] (d) Collect the product by centrifugation, wash the product three times with ethanol, and then dry it in a vacuum oven at 60°C for 12 hours to obtain the precursor Co-BTC;

[0051] (2) Preparation of Co with hollow nanostructure 2 P@C composite materials:

[0052] The Co-BTC material prepared by 0.1g step (1) and 1g sodium hypophosphite NaH 2 PO 2 Put them ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com