Composite photocatalysis material for degrading rhodamine B and preparation method and application of material

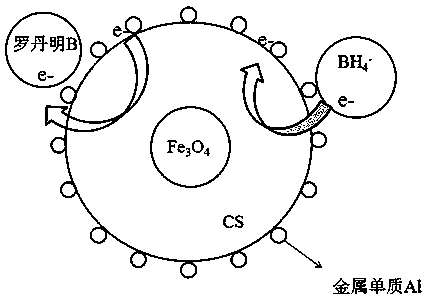

A composite material and photocatalytic technology, which is applied in the field of photocatalytic composite materials for degrading rhodamine B and its preparation, can solve the problems of human health and ecosystem threats, difficult to be widely used, and high processing costs, and achieve good reducibility and stability. high catalytic activity and selectivity, easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a photocatalytic composite material for degrading rhodamine B, comprising the following steps:

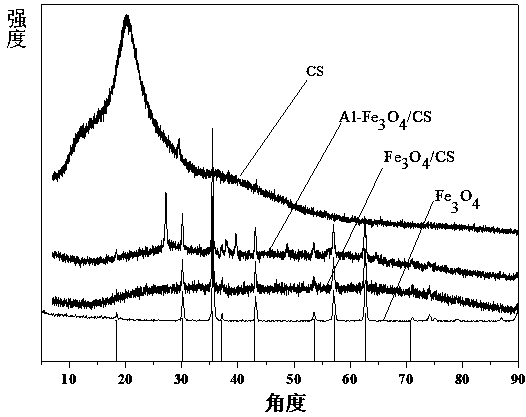

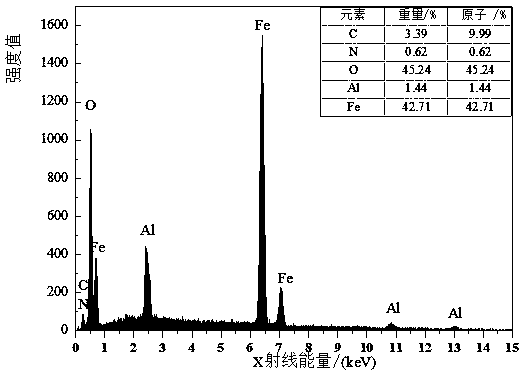

[0028] S1. Preparation of matrix magnetic Fe 3 o 4 Particles, the specific steps are as follows: Measure 8mL of 0.02mol / L FeCl 3 ·6H 2 0 solution and 8mL of 0.01mol / L FeCl 2 4H 2 0 solution was mixed into a 100mL three-necked flask, mechanically stirred for 5min at a stirring rate of 200rpm, fed with nitrogen as a protective gas and placed in a constant temperature water bath at 60°C, using a peristaltic pump at a rate of 3mL / min under a mechanical stirring condition of 200rpm Add 1 mol / L ammonia water dropwise to the three-necked flask to adjust the pH of the solution to 10, stop adding ammonia water and continue the reaction for 1 hour, so that the magnetic Fe produced by the co-precipitation method 3 o 4 The particle size and shape are more uniform; then the mixed solution is magnetically separated and filtered, washed with deionized water an...

Embodiment 2

[0033] A preparation method of a photocatalytic composite material for degrading rhodamine B, comprising the following steps:

[0034] S1. Preparation of matrix magnetic Fe 3 o 4 Particles: Take 5mL of FeCl with a concentration of 0.03mol / L 3 ·6H 2 O solution and 5 mL of FeCl with a concentration of 0.01 mol / L 2 4H 2 O solution was mixed, mechanically stirred at 200rpm for 5min, under the protection of nitrogen, continued to stir, and under the condition of a constant temperature water bath at a temperature of 50°C, a peristaltic pump was used to drop the substance into the mixed solution at a rate of 3mL / min. The concentration was 1mol / min. L ammoniacal liquor, continue to stir, and the ammoniacal liquor is added dropwise to the pH value of mixed solution to 10, stops dripping ammoniacal liquor and continues reaction 1h, makes the magnetic Fe that co-precipitation method produces 3 o 4 The particle size and shape are more uniform; then the mixed solution is magnetically...

Embodiment 3

[0038] A preparation method of a photocatalytic composite material for degrading rhodamine B, comprising the following steps:

[0039] S1. Preparation of matrix magnetic Fe 3 o 4 Particles: Take 6.5mL of FeCl with a concentration of 0.01mol / L 3 ·6H 2 O solution and 6.5 mL of FeCl with a concentration of 0.01 mol / L 2 4H 2 O solution was mixed, mechanically stirred at 200rpm for 5min, under nitrogen protection, continued to stir, and under the condition of a constant temperature water bath at 70°C, use a peristaltic pump to drop the substance into the mixed solution at 3mL / min with a concentration of 1mol / L ammonia water , continue to stir, add ammonia water dropwise until the pH value of the mixed solution reaches 10, stop dripping ammonia water and continue the reaction for 1 hour, so that the magnetic Fe produced by the co-precipitation method 3 o 4 The particle size and shape are more uniform; then the mixed solution is magnetically separated and filtered, washed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com