Method for enabling novel low-eutectic ionic liquid to chemically fix carbon dioxide under normal pressure and temperature condition to synthesize cyclic carbonate

A technology of cyclic carbonates and ionic liquids, applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the problems of harsh reaction conditions and low catalytic activity, and achieve low price and simple synthesis The effect of high efficiency and great development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The synthesis of embodiment 1 novel deep eutectic ionic liquid

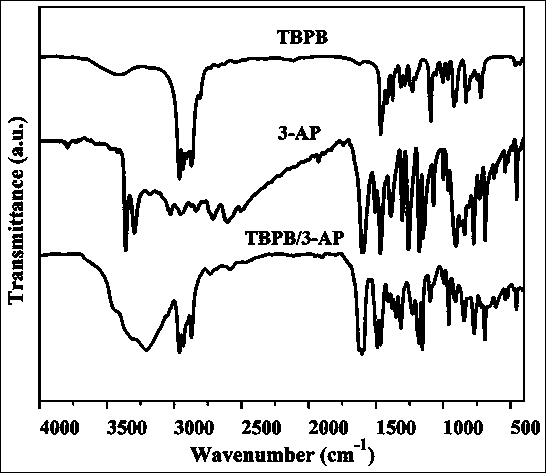

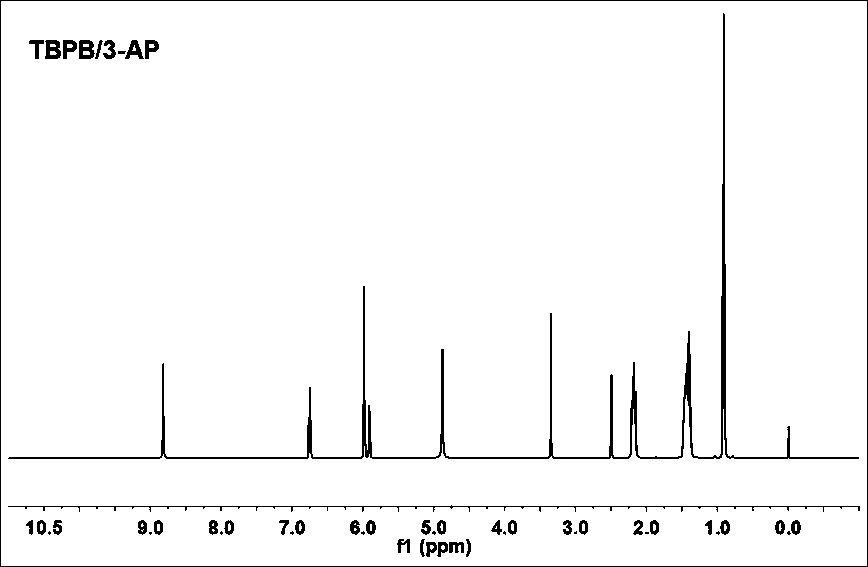

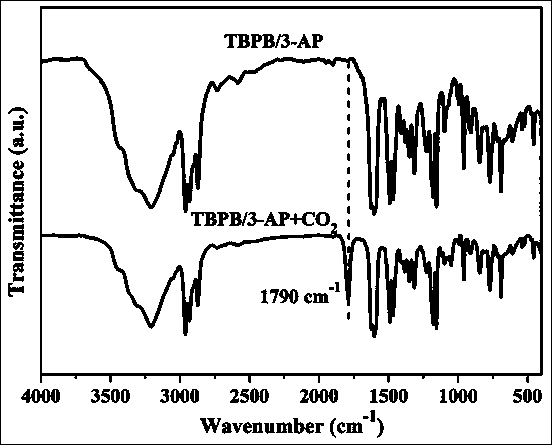

[0025] Prepared by adding tetrabutylphosphonium bromide (TBPB) and m-aminophenol (3-AP) into single-necked flasks at a molar ratio of 1:2, and heating and magnetically stirring at 50°C for 0.5 hours. TBPB / 3-AP was obtained. attached figure 1 The structure of TBPB / 3-AP was characterized by infrared; figure 2 The structure of TBPB / 3-AP was characterized by NMR; image 3 Infrared characterization of TBPB / 3-AP on CO 2 activation.

[0026] Methyltriphenylphosphonium bromide (MTPB) and p-aminophenol (4-AP) were added to a single-necked flask at a molar ratio of 1:3, heated and magnetically stirred at 50°C for 0.5 hours to prepare And get MTPB / 4-AP.

[0027] Allyltriphenylphosphonium bromide (ATPB) and o-aminophenol (2-AP) were added to a single-necked flask at a molar ratio of 1:2, heated and magnetically stirred at 50°C for 0.5 hours, Prepared to obtain ATPB / 2-AP.

[0028] Benzyltriphenylphosphonium br...

Embodiment 2

[0030] Get the catalyst TBPB / 3-AP prepared in Example 1 and the reactant epichlorohydrin and add 100mL successively to connect CO 2 The Schlenk (Schlenk) reaction flask of balloon, wherein, epichlorohydrin 10mmol, TBPB-NHS 0.8mmol, catalyst accounts for epichlorohydrin molar content and is 8mol%, decompression gets rid of the air remaining inside; Reaction flask and CO 2 Balloon connected, at a reaction temperature of 25°C, 0.1MPa CO 2 Under pressure conditions, the reaction continued for 24 hours; after the reaction, the product was quantitatively analyzed by gas chromatography, and the corresponding product yield was 96%, and the selectivity was 99%.

Embodiment 3

[0032] The specific experimental process and detection method are the same as in Example 2, the deep eutectic ionic liquid is changed to the MTPB / 4-AP prepared in Example 1, the catalyst consumption is changed to account for 5mol% of the epichlorohydrin molar content, and the reaction time is changed to 12 hours, the corresponding product yield is 83%, and the selectivity is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com