Extraction of high activity milk thistle oil and preparation method of microcapsule of high activity milk thistle oil

A technology of milk thistle oil and high activity, which is applied in the biological field to achieve the effects of increasing content, improving physical and chemical properties, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

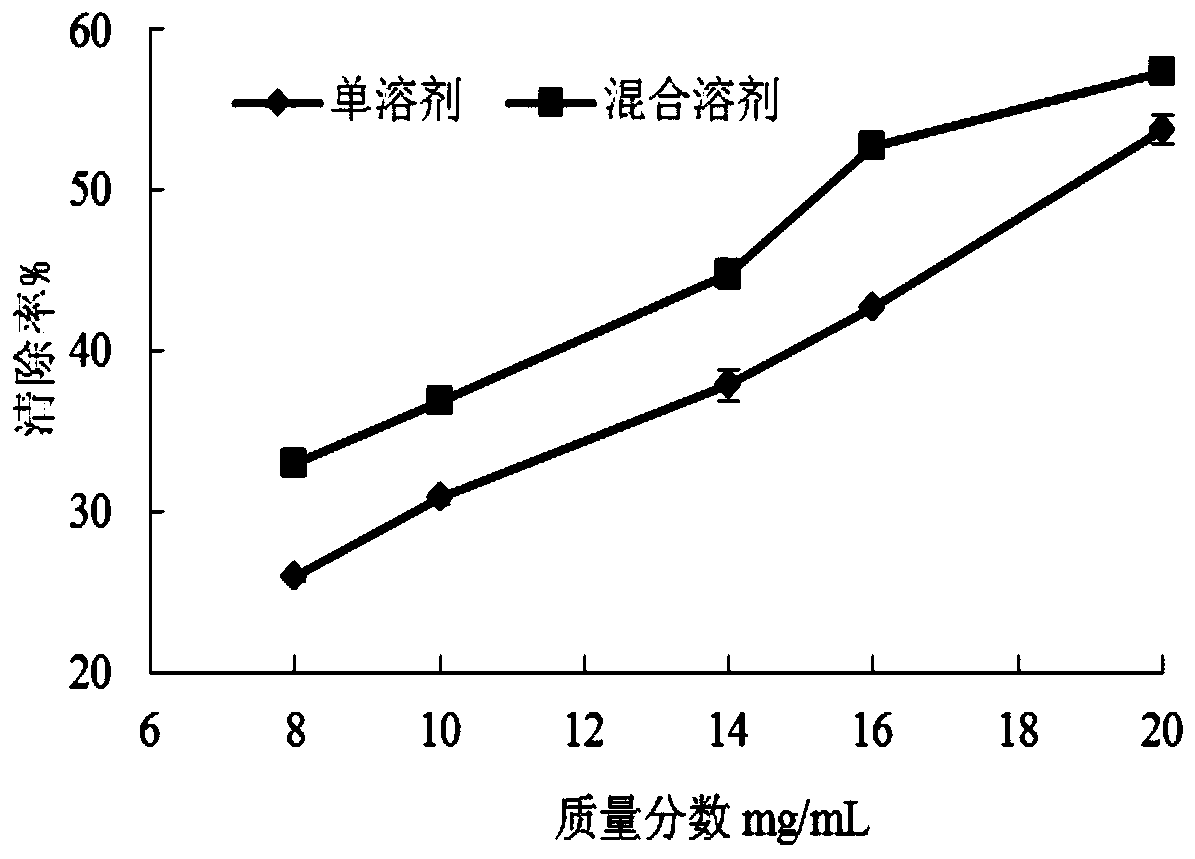

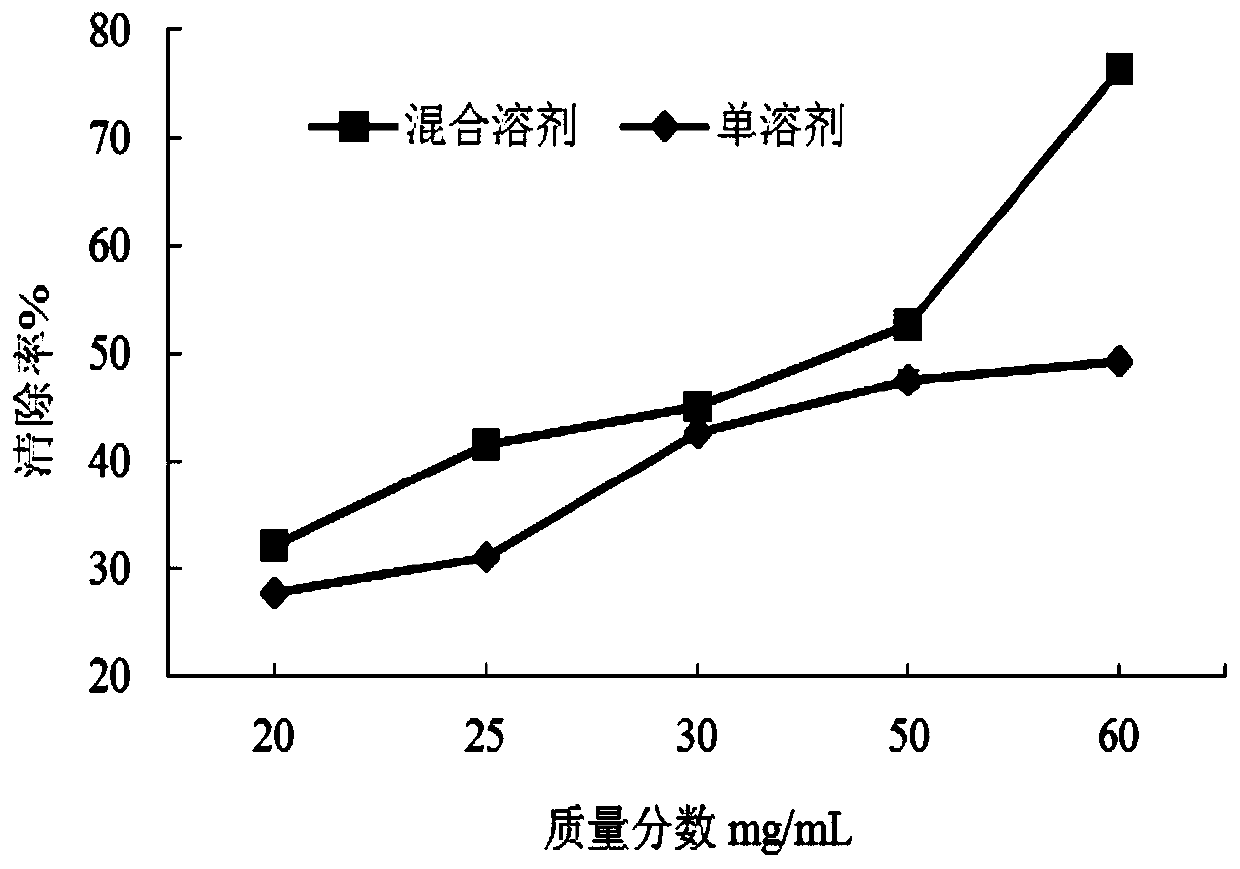

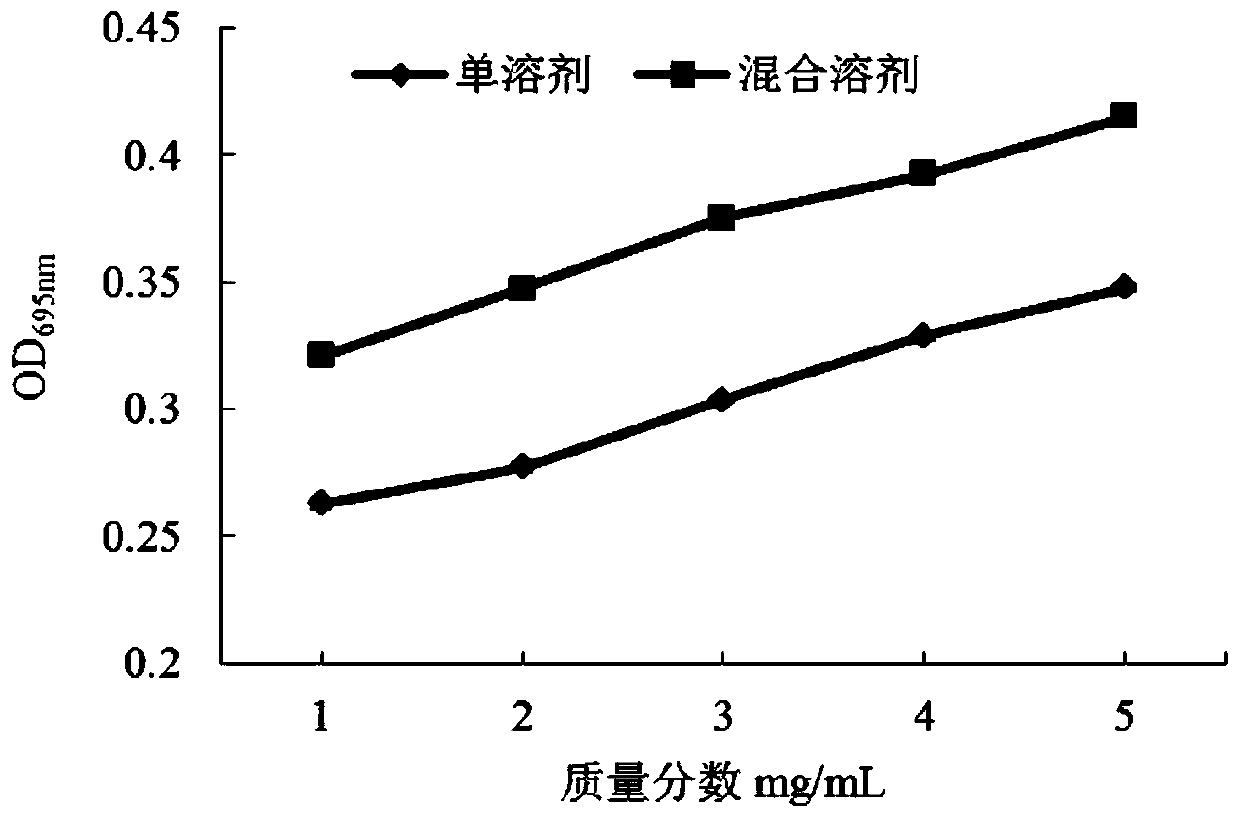

[0027] (1) choose the milk thistle seed with complete particle, adopt mechanical pulverization, the material after pulverizing passes 60 mesh sieves; Then sherwood oil and dehydrated alcohol are mixed with volume ratio 7:3, obtain mixed solvent; Milk thistle powder Mix evenly with the mixed solvent at the ratio of material to liquid 1:3, ultrasonically extract for 10min under the condition of ultrasonic power of 100W; centrifuge the mixed solution for 20min under the condition of rotating speed of 5000r / min, remove the residue and then vacuum concentrate and recover the solvent Then dry to obtain milk thistle oil;

[0028] (2) Add milk thistle oil to a fully dissolved gum arabic solution with a mass fraction of 1% to obtain a mixed solution A, then add monoglyceride as an emulsifier, and stir at a high speed for 3 minutes at a speed of 10000 r / min Make an emulsion, then add a soybean protein isolate solution with a mass fraction of 1% dropwise at 45°C with a magnetic stirring ...

Embodiment 2

[0031] (1) choose the milk thistle seed with complete particle, adopt mechanical pulverization, the material after pulverizing passes 60 mesh sieves; Then sherwood oil and dehydrated alcohol are mixed with volume ratio 7:3, obtain mixed solvent; Milk thistle powder Mix evenly with the mixed solvent at the ratio of solid to liquid 1:7, ultrasonically extract for 40min under the condition of ultrasonic power of 300W; centrifuge the mixed solution for 20min under the condition of rotating speed of 5000r / min, remove the residue and then vacuum concentrate and recover the solvent Then dry to obtain milk thistle oil;

[0032] (2) Add milk thistle oil to a fully dissolved gum arabic solution with a mass fraction of 3% to obtain a mixed solution A, then add monoglyceride as an emulsifier, and stir at a high speed for 2 minutes at a speed of 5000 r / min Prepare an emulsion, and then add a soybean protein isolate solution with a mass fraction of 3% dropwise at 45°C under the condition of...

Embodiment 3

[0035](1) choose the milk thistle seed with complete particle, adopt mechanical pulverization, the material after pulverizing passes 60 mesh sieves; Then sherwood oil and dehydrated alcohol are mixed with volume ratio 7:3, obtain mixed solvent; Milk thistle powder Mix evenly with the mixed solvent at the ratio of solid to liquid 1:4, ultrasonically extract for 20min under the condition of ultrasonic power of 240W; centrifuge the mixed solution for 20min under the condition of rotating speed of 5000r / min, remove the residue and then vacuum concentrate and recover the solvent Then dry to obtain milk thistle oil;

[0036] (2) Add milk thistle oil to a fully dissolved gum arabic solution with a mass fraction of 5% to obtain a mixed solution A, then add monoglyceride as an emulsifier, and stir at a high speed for 5 minutes at a speed of 20,000 r / min Make an emulsion, and then add a soybean protein isolate solution with a mass fraction of 5% dropwise at 45°C under the condition that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com