Method for preparing biostimulant by utilizing amino acid fermentation tail liquid

A technology of biostimulants and fermentation tails, applied in the fields of chemicals for biological control, botanical equipment and methods, applications, etc., can solve problems such as increasing the burden on enterprises, corrosion, etc., to promote plant growth and improve hydrolysis rate , improve the ability of enzyme production and the effect of cell membrane permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a biostimulant using amino acid fermentation tail liquid, comprising the steps of:

[0030] Step 1) Separation, drying and crushing: the amino acid fermentation tail liquid is separated by a disc separator with a rotation speed of 5000 rpm and a centrifugation time of 3 minutes to collect bacterial protein precipitates and waste mother liquor, then dry the bacterial precipitates, and then The pulverizer is crushed into bacterial protein powder;

[0031] Step 2) Concentration: Concentrate the waste mother liquor to one-fifth of the original volume to obtain a concentrate;

[0032] Step 3) Microbial enzymatic hydrolysis treatment: Inoculate Aspergillus niger ATCC 16404 into the medium of the seed tank for cultivation, the temperature is controlled at 30°C, and the cultivation is carried out until the bacterial concentration is 1.0×10 8 cfu / ml, to obtain the seed liquid; the composition of the seed tank culture medium is: 20g / L glucose, 6g / L corn st...

Embodiment 2

[0036] A method for preparing a biostimulant using amino acid fermentation tail liquid, comprising the steps of:

[0037] Step 1) Separation, drying and crushing: the amino acid fermentation tail liquid is separated by a disc separator with a rotation speed of 5000 rpm and a centrifugation time of 3 minutes to collect bacterial protein precipitates and waste mother liquor, then dry the bacterial precipitates, and then The pulverizer is crushed into bacterial protein powder;

[0038] Step 2) Concentration: Concentrate the waste mother liquor to one-fifth of the original volume to obtain a concentrate;

[0039] Step 3) Microbial enzymatic hydrolysis treatment: Inoculate Aspergillus niger ATCC 16404 into the medium of the seed tank for cultivation, the temperature is controlled at 30°C, and the cultivation is carried out until the bacterial concentration is 1.0×10 8 cfu / ml to obtain seed liquid; the composition of the seed tank culture medium is: 20g / L glucose, 6g / L corn steep l...

Embodiment 3

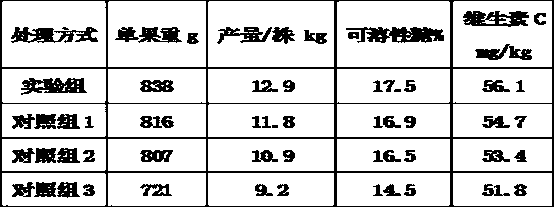

[0043] Effects of different treatment methods on the degree of proteolysis of bacteria:

[0044] The components in the amino acid fermentation tail liquid of the present invention are as follows (dry basis %): bacterial protein 35.2, amino acid 14.1, polysaccharides 5.3, ammonia nitrogen 9.9, sulfur 9.0, calcium 3.2, potassium 1.3, iron 0.9, and the balance is other .

[0045] Set group:

[0046] Take embodiment 1 as experimental group;

[0047] Control group 1: use 6mol / L hydrochloric acid to hydrolyze the bacterial protein with stirring and hydrolysis at a temperature of 60°C for 16 hours, and the rest of the operations are the same as in Example 1;

[0048] Control group 2: 2mol / L hydrochloric acid was used to hydrolyze the bacterial protein with stirring and hydrolysis at 60°C for 32 hours, and the rest of the operations were the same as in Example 1;

[0049] Control group 3: do not add tourmaline powder, all the other operations are the same as embodiment 1;

[0050]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com