a worm-like ni/ni x fe 1-x o y Hydrogen evolution catalyst and preparation method thereof

A worm-like, catalytic technology, applied in the field of electrocatalytic materials, can solve the problems of full contact of electrolyte, poor stability, and activity attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Substrate pretreatment: Cut the pure copper sheet into a rectangle with a size of 1×3.5cm, clean the cut pure copper sheet ultrasonically in acetone for 20 minutes, then ultrasonically clean it in absolute ethanol for 20 minutes, and then use 10% Pickle with dilute sulfuric acid solution for 60s, take it out and ultrasonically clean it with deionized water to avoid acid residue, and rinse with a large amount of deionized water between each step.

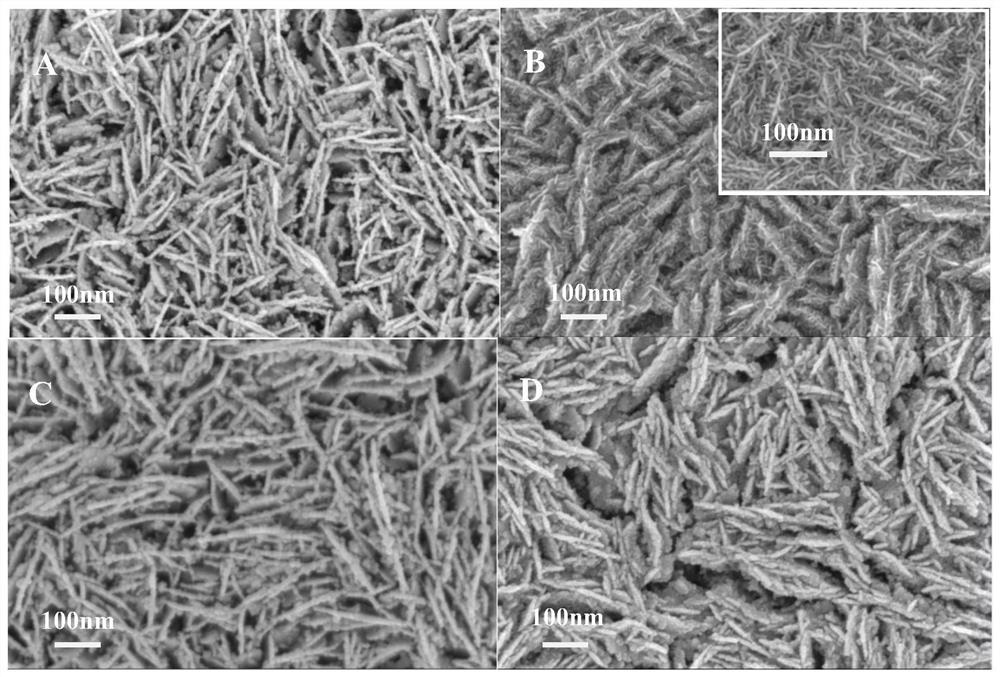

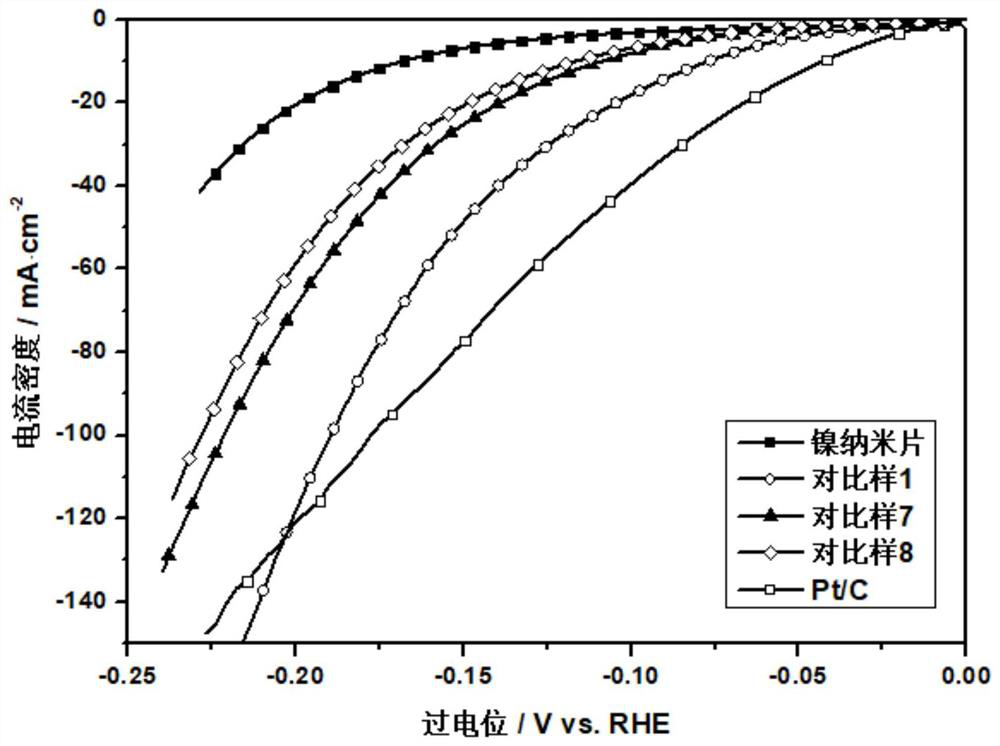

[0043] (2) Electrodeposition of nickel nanosheets: Prepare a 0.3M nickel sulfate solution with deionized water, the temperature of the electrolyte is 25°C, and the electrodeposition time is 7 minutes. The sample pretreated in step (1) is clamped on the fixture. Electrodeposition was carried out on a CHI660 electrochemical workstation, using a three-electrode system, a graphite rod as a counter electrode, a saturated calomel electrode as a reference electrode, and a pretreated copper sheet as a working electrode. Constant volt...

Embodiment 2

[0046] (1) substrate pretreatment, same as embodiment 1 step (1);

[0047] (2) Electrodeposition of nickel nanosheets is the same as in Example 1 step (2);

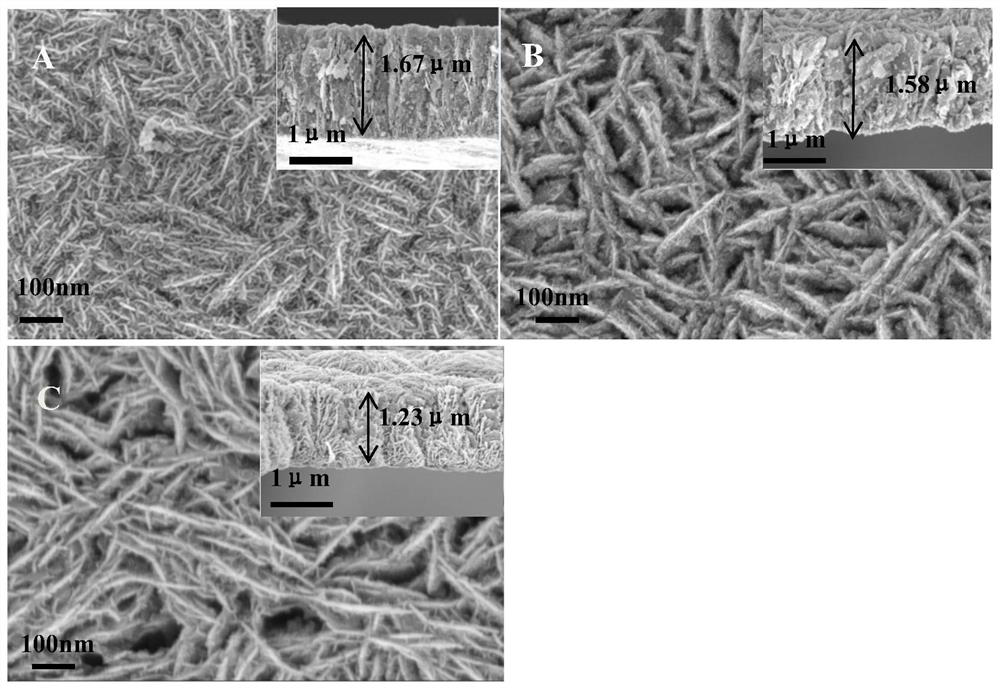

[0048] (3) Vermicular Ni / Ni x Fe 1-x o y Preparation of hydrogen evolution catalyst: Prepare lye with deionized water, including 1mol / L sodium hydroxide, 0.2mol / L ammonium fluoride and 0.3g / L CTAB, and then separately prepare 0.2mol / L nickel acetate solution and 0.2mol / L L of ferrous ammonium sulfate solution, put the lye in a YLD-6000 low-temperature water bath to keep the temperature constant, set the temperature at 85°C, and keep it warm for 20 minutes, then use a disposable rubber head dropper to mix the prepared nickel acetate solution and sulfurous acid The ferric ammonium solution is gradually added dropwise to the alkaline solution until a small amount of precipitation occurs in the solution. Afterwards, place the electrodeposited nickel nanosheets in lye, soak for 2 hours, take them out, rinse them with deion...

Embodiment 3

[0050] (1) substrate pretreatment, same as embodiment 1 step (1);

[0051] (2) Electrodeposition of nickel nanosheets is the same as in Example 1 step (2);

[0052] (3) Vermicular Ni / Ni x Fe 1-x o y Preparation of hydrogen evolution catalyst: Prepare lye with deionized water, including 1mol / L sodium hydroxide, 0.2mol / L ammonium fluoride and 0.2g / L CTAB, and then separately prepare 0.2mol / L nickel acetate solution and 0.2mol / L L of ferrous ammonium sulfate solution, put the sodium hydroxide solution in a YLD-6000 low-temperature water bath to keep the temperature constant, set the temperature at 65°C, keep it warm for 20 minutes, and use a disposable plastic head dropper to mix the prepared nickel acetate solution and The ferrous ammonium sulfate solution is gradually added dropwise to the lye until a small amount of precipitation occurs in the solution. Afterwards, place the electrodeposited nickel nanosheets in lye, soak for 3 hours, take them out, rinse them with deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com