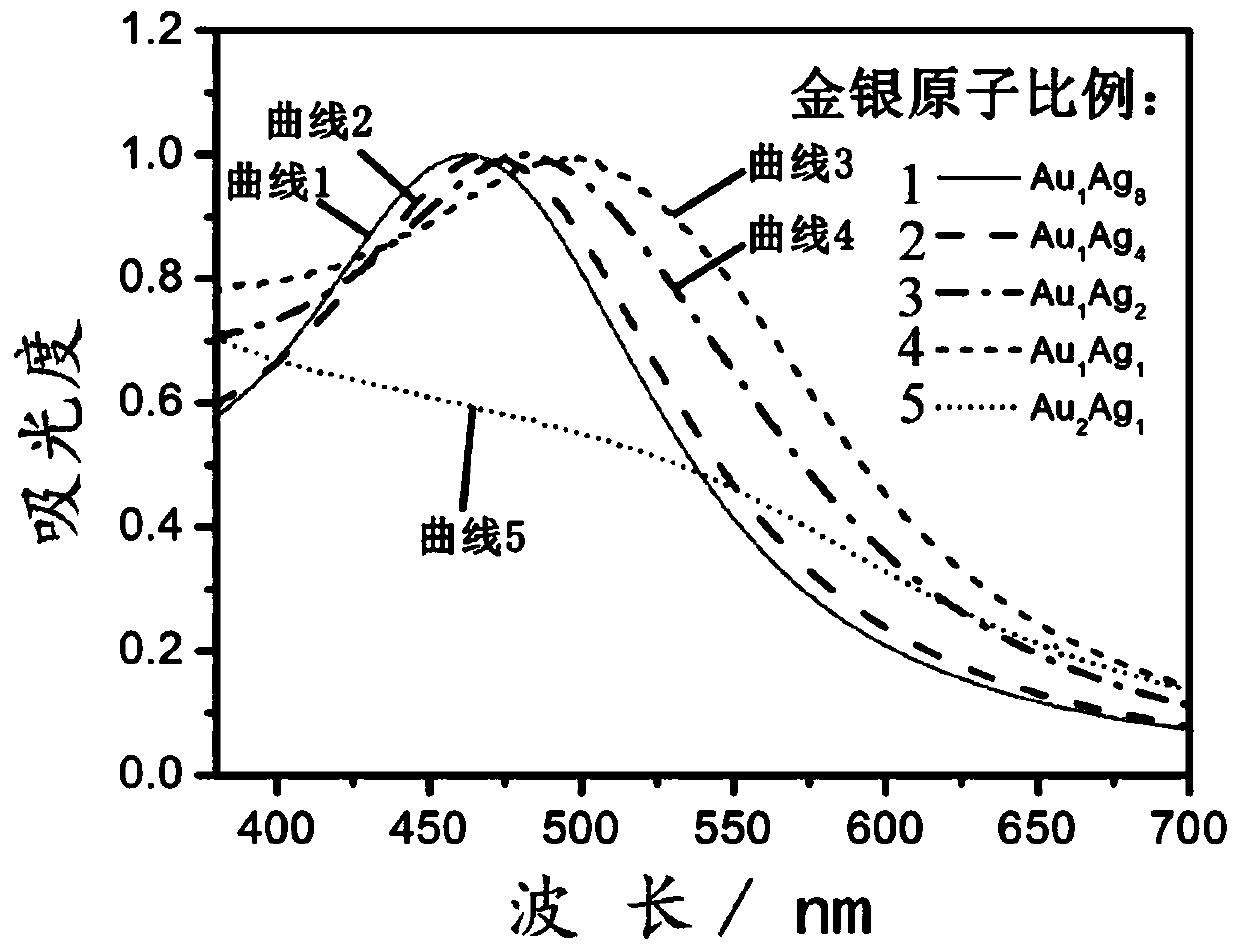

Preparation and application of gold-silver alloy nanoparticles for metal micro-nano structure assembly

A nanoparticle, gold-silver alloy technology, applied in metal processing equipment, nanotechnology, transportation and packaging, etc., to achieve uniform size distribution, high preparation efficiency, and good solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

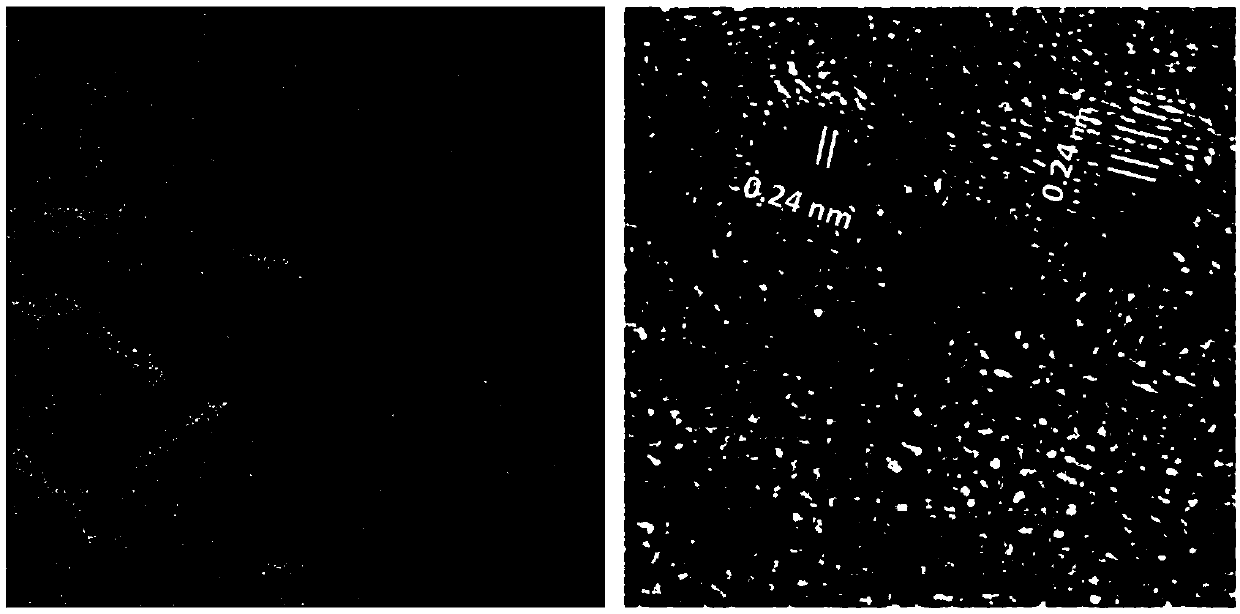

Embodiment 1

[0029] Under stirring conditions, 1.5g of tetrabutylammonium bromide was dissolved in 80mL of toluene to form a solution with a mass concentration of about 2%, and then 4.66ml of 2.0mol / L nitric acid was added. Add 0.35g (2.08mmol) AgNO to the above solution under stirring condition 3 , after the solution is clear and transparent, add 0.11g (0.26mmol) HAuCl to the reaction solution 4 4H 2 O, the toluene phase is reddish brown, and the water phase is separated after the water phase is colorless and transparent. Then 1.4 g of dodecylmercaptan was added to the reaction solution, and the solution was heated to 30-35°C. Finally, pour 21 mL of 4% sodium borohydride aqueous solution into the reactor, and continue heating and stirring for 24 h. Wherein, the molar ratio of each reactant: tetrabutylammonium bromide, nitric acid, noble metal salt, dodecyl mercaptan, and sodium borohydride is 2:4:1:3:10. After the reaction, the water phase was separated, and the organic phase was dist...

Embodiment 2

[0031] Under the condition of stirring, 1.524g of tetraoctylammonium bromide was dissolved in 80mL of toluene to form a solution with a mass concentration of 2%, and then 3.25ml of 1.5mol / L sulfuric acid was added. Add 0.231g (1.36mmol) AgNO to the above solution under stirring condition 3 , after the solution is clear and transparent, add 0.14g (0.34mmol) HAuCl to the reaction solution 4 4H 2O, the toluene phase is reddish brown, and the water phase is separated after the water phase is colorless and transparent. Then, 0.494 g of n-hexanethiol was added to the reaction solution, and the solution was heated to 30-35°C. Finally, pour 20 mL of 1.8% sodium borohydride aqueous solution into the reactor, and continue heating and stirring for 12 h. Wherein, the molar ratio of each reactant: tetraoctylammonium bromide, sulfuric acid, noble metal salt, n-hexanethiol, and sodium borohydride is 2:3.5:1:3:7. After the reaction, the water phase was separated, and the organic phase was...

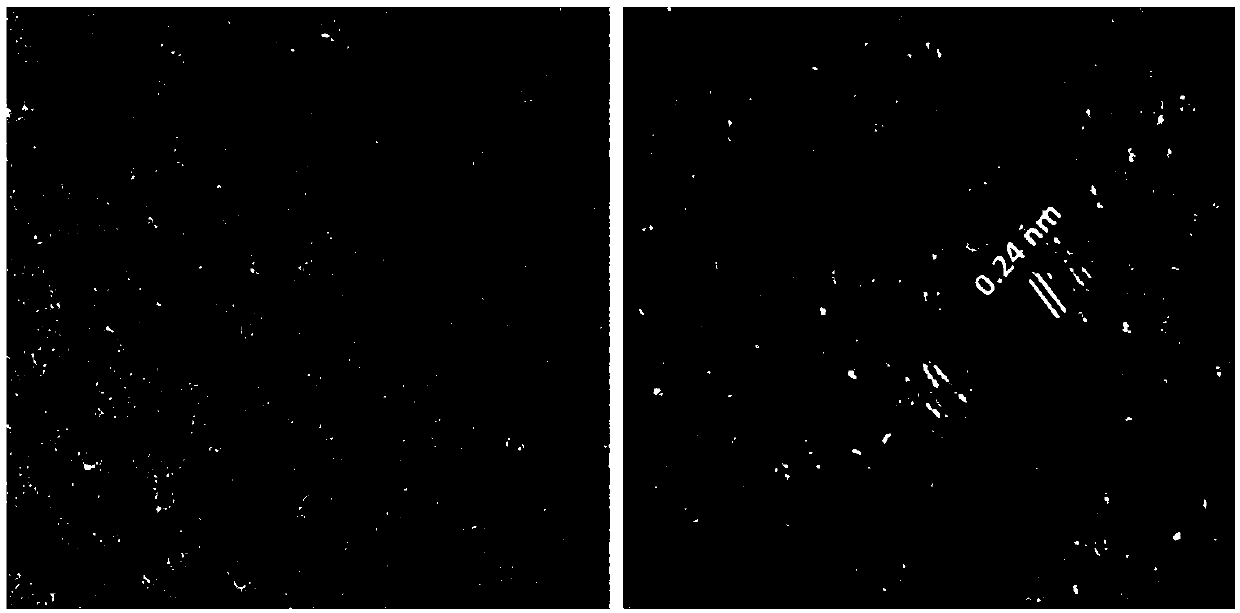

Embodiment 3

[0033] Under stirring conditions, 1.25 g of tetraoctyl ammonium chloride was dissolved in 70 mL of toluene to form a solution with a mass concentration of 2%, and then 3.7 ml of 1.0 mol / L hydrochloric acid was added. Add 0.105g (0.62mmol) AgNO to the above solution under stirring condition 3 , after the solution is clear and transparent, add 0.255g (0.62mmol) HAuCl to the reaction solution 4 4H 2 O, the toluene phase is reddish brown, and the water phase is separated after the water phase is colorless and transparent. Then 0.36 g of n-octyl mercaptan was added to the reaction solution, and the solution was heated to 30-35°C. Finally, 20 mL of an aqueous solution with a mass concentration of 1.8% was poured into the reactor, and heating and stirring were continued for 12 h. Wherein, the molar ratio of each reactant: tetraoctyl ammonium chloride, hydrochloric acid, noble metal salt, n-octyl mercaptan, and sodium borohydride is 2:3:1:2:8. After the reaction, the water phase w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com