Method for treating rural domestic sewage by utilizing water supply sludge

A technology for water supply sludge and domestic sewage, applied in water/sludge/sewage treatment, sludge treatment, water/sewage treatment, etc., can solve the problems of low adsorption capacity and low sewage treatment efficiency, and achieve long service life , The effect of enhancing ammonia nitrogen removal capacity and increasing treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

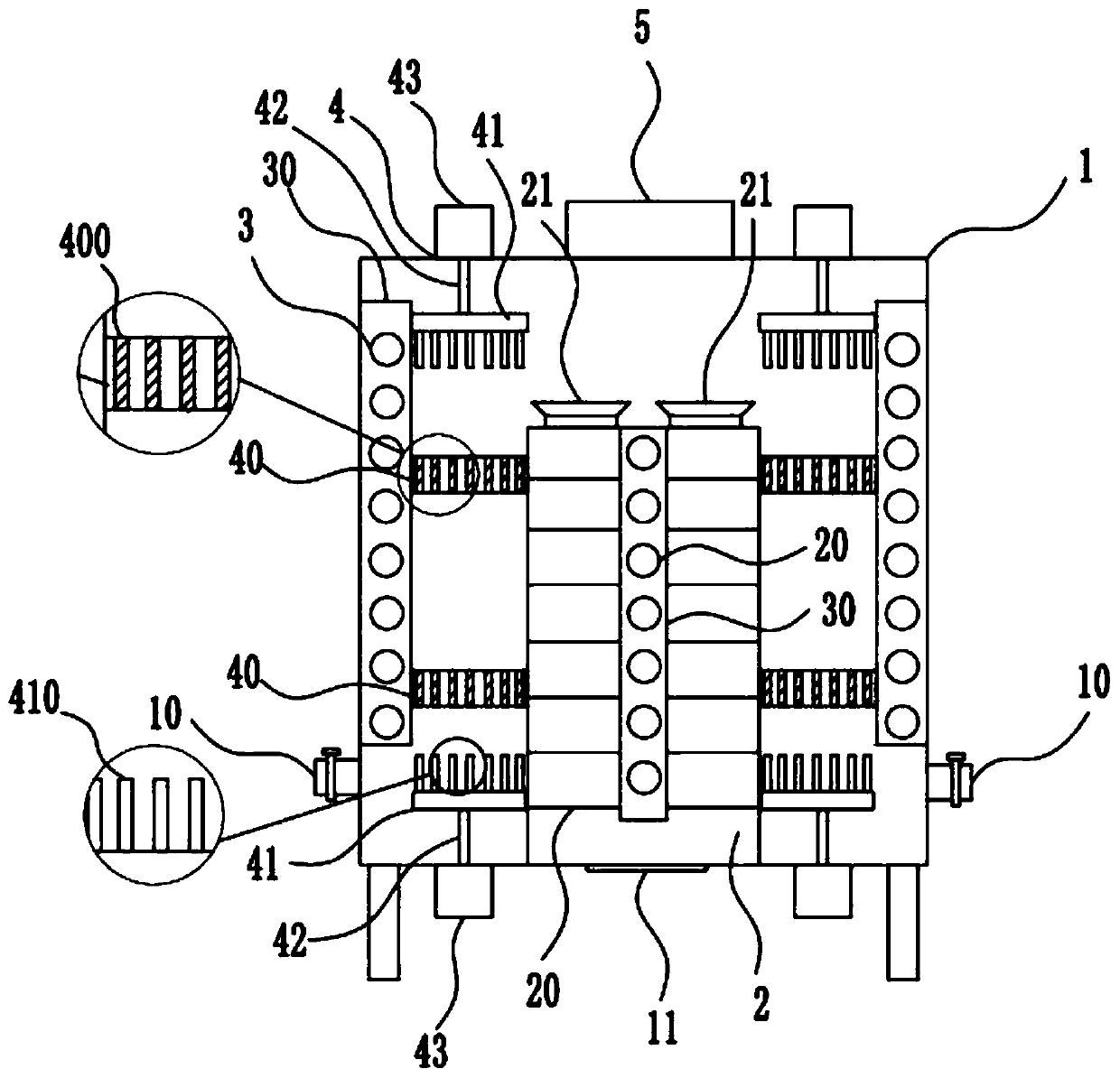

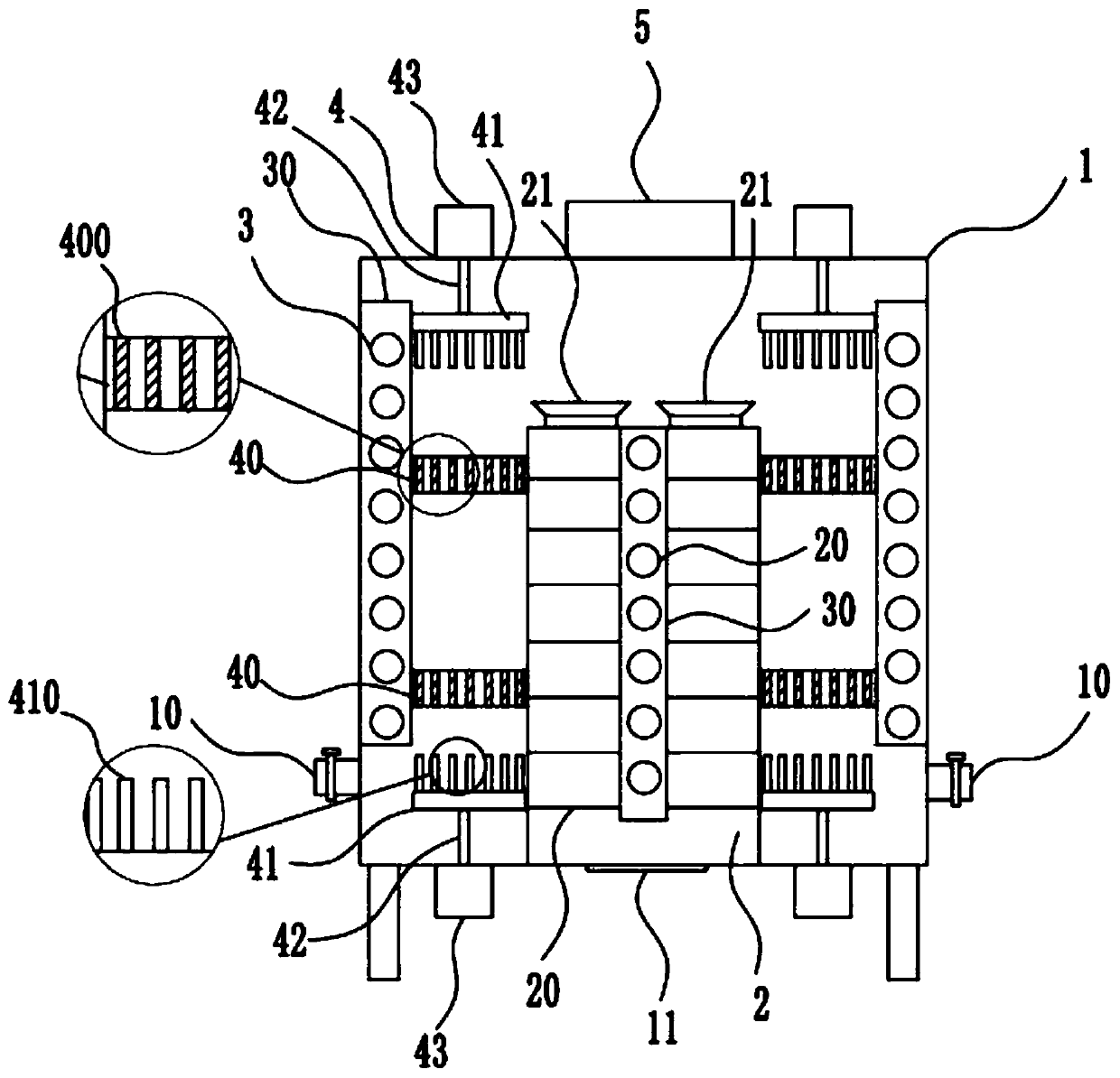

Image

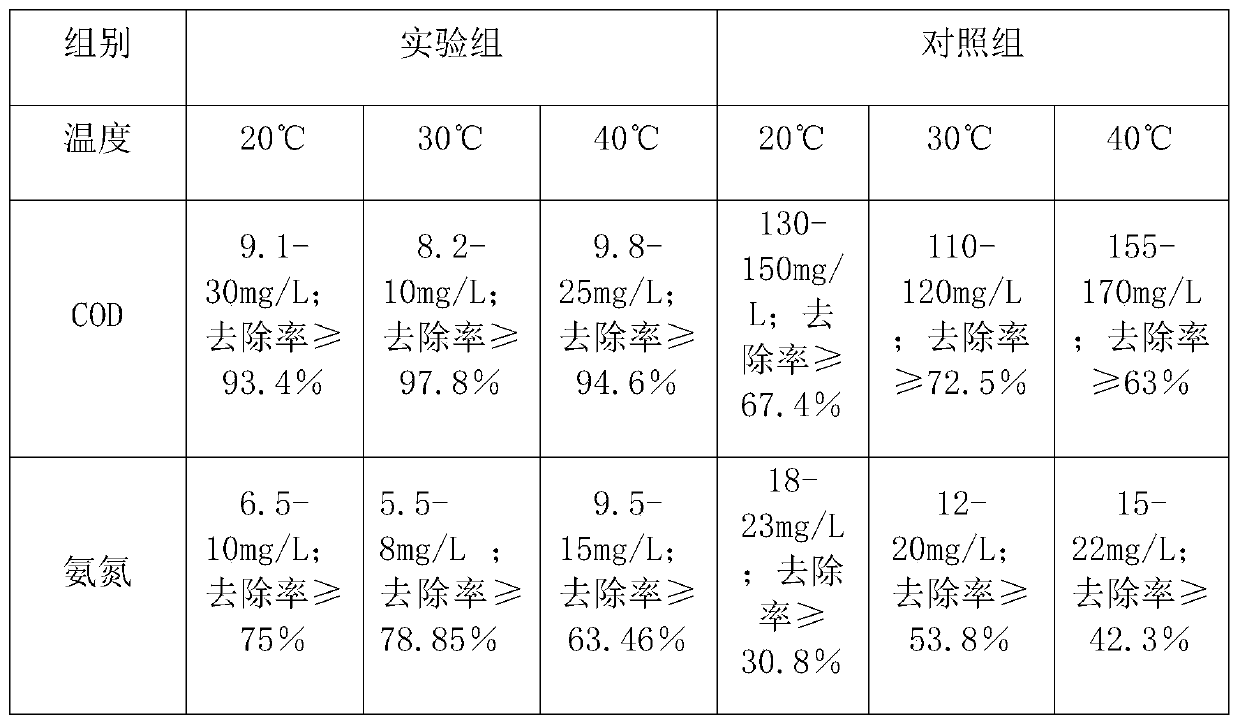

Examples

Embodiment 1

[0030] A method for treating rural domestic sewage by using water supply sludge mainly includes the following steps:

[0031] (1) Take an appropriate amount of feedwater sludge and put it into a mixer, stir at 70°C for 15 minutes, and inject concentrated solidification additives into the feedwater sludge according to 3% of the weight of the feedwater sludge for mixing, and the injection flow rate is 0.3L / min, then stir at a speed of 80r / min until evenly stirred;

[0032] (2) Precipitate the mixture prepared in step (1) for 3 days, remove the supernatant, put the remaining sediment into a diaphragm filter press for filtration to form a feedwater sludge filter press, and put the feedwater sludge filter press into Rotate at a speed of 45r / min in a vacuum environment, and feed argon gas until the vacuum degree is 15Pa, ionize the argon gas into argon ions, and perform plasma sputtering on the surface of the feedwater sludge filter block to make the feedwater sludge filter press ...

Embodiment 2

[0038] A method for treating rural domestic sewage by using water supply sludge mainly includes the following steps:

[0039] (1) Take an appropriate amount of feedwater sludge and put it into a mixer, stir at 85°C for 18 minutes, and inject concentrated solidification additives into the feedwater sludge according to 8% of the weight of the feedwater sludge for mixing, and the injection flow rate is 0.5L / min, then stir at a speed of 100r / min until evenly stirred;

[0040] (2) Precipitate the mixture prepared in step (1) for 5 days, remove the supernatant, put the remaining sediment into a diaphragm filter press for filtration to form a feedwater sludge filter press, and put the feedwater sludge filter press into Rotate at a speed of 50r / min in a vacuum environment, and feed argon gas until the vacuum degree is 20Pa, ionize the argon gas into argon ions, and perform plasma sputtering on the surface of the feedwater sludge filter block to make the feedwater sludge filter press ...

Embodiment 3

[0046] A method for treating rural domestic sewage by using water supply sludge mainly includes the following steps:

[0047] (1) Take an appropriate amount of feedwater sludge and put it into a mixer, stir at 85°C for 20 minutes, and inject concentrated solidification additives into the feedwater sludge according to 12% of the weight of the feedwater sludge for mixing, and the injection flow rate is 0.6L / min, then stir at a speed of 120r / min until evenly stirred;

[0048] (2) Precipitate the mixture prepared in step (1) for 6 days, remove the supernatant, put the remaining sediment into a diaphragm filter press for filtration to form a feedwater sludge filter press, and put the feedwater sludge filter press into Rotate at a speed of 60r / min in a vacuum environment, and pass in argon gas until the vacuum degree is 25Pa, ionize the argon gas into argon ions, and perform plasma sputtering on the surface of the feedwater sludge filter block to make the feedwater sludge filter pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com