A preparation method of dual-response hydrogel ink

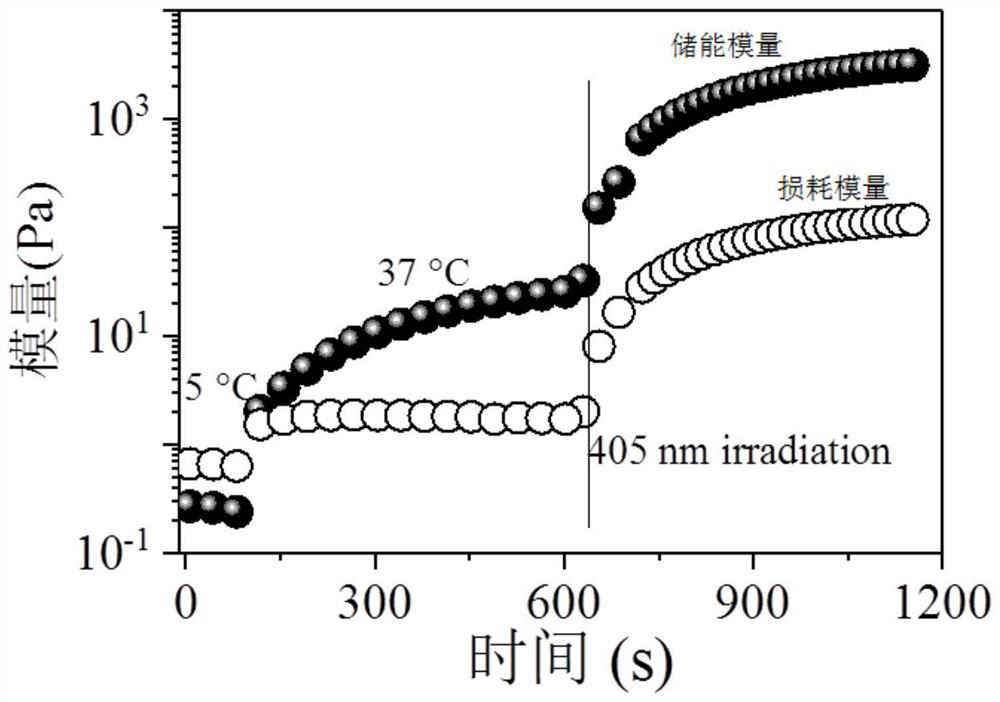

A hydrogel, dual-response technology, applied in the field of preparation of dual-response hydrogel ink, can solve the problems of poor reversible temperature response and low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a double-response hydrogel ink of the present invention is specifically implemented according to the following steps:

[0031] Step 1, using the nucleophilic addition reaction of acryloyl chloride and the hydroxyl group of Pluronic F127 to prepare acryloyl F127 (F127DA), specifically:

[0032] Step 1.1: Dissolve Pluronic F127 in anhydrous dichloromethane, place in an ice-water bath at 0°C to 4°C, add triethylamine, and pass through nitrogen for 15 to 20 minutes to obtain a mixture a;

[0033] The molar ratio of Pluronic F127, anhydrous dichloromethane and triethylamine is 1:5:10~20;

[0034] Step 1.2: Add acryloyl chloride dropwise to the mixed liquid a obtained after step 1.1 at a rate of 1 to 2 drops per second, and then place it in an ice-water bath at 0°C to 4°C for 48h to 60h to obtain a reaction mixture , and then filter the reaction mixture, remove the filter residue, and obtain the reaction solution;

[0035] The mass ratio of acryloyl c...

Embodiment 1

[0054] A method for preparing a double-response hydrogel ink of the present invention is specifically implemented according to the following steps:

[0055] Step 1, using the nucleophilic addition reaction of acryloyl chloride and the hydroxyl group of Pluronic F127 to prepare acryloyl F127 (F127DA), specifically:

[0056] Step 1.1: Dissolve Pluronic F127 in anhydrous dichloromethane, place in an ice-water bath at 0°C, add triethylamine, and pass through nitrogen for 15 minutes to obtain a mixture a;

[0057] The molar ratio of Pluronic F127, anhydrous dichloromethane and triethylamine is 1:5:10;

[0058] Step 1.2: Add acryloyl chloride dropwise to the mixture a obtained after step 1.1 at a rate of 1 drop per second, and then place it in an ice-water bath at 0°C for 48 hours to obtain a reaction mixture, and then filter the reaction mixture , remove filter residue, obtain reaction solution;

[0059] The mass ratio of acryloyl chloride to mixed liquid a is 1:10;

[0060] Ste...

Embodiment 2

[0077] A method for preparing a double-response hydrogel ink of the present invention is specifically implemented according to the following steps:

[0078] Step 1, using the nucleophilic addition reaction of acryloyl chloride and the hydroxyl group of Pluronic F127 to prepare acryloyl F127 (F127DA), specifically:

[0079] Step 1.1: Dissolve Pluronic F127 in anhydrous dichloromethane, place in an ice-water bath at 0°C, add triethylamine, and pass through nitrogen for 18 minutes to obtain a mixture a;

[0080] The molar ratio of Pluronic F127, anhydrous dichloromethane and triethylamine is 1:5:15;

[0081] Step 1.2: Add acryloyl chloride dropwise to the mixture a obtained after step 1.1 at a rate of 1 drop per second, and then place it in an ice-water bath at 2°C for 50 hours to obtain a reaction mixture, and then filter the reaction mixture , remove filter residue, obtain reaction solution;

[0082] The mass ratio of acryloyl chloride to mixed liquid a is 1:12;

[0083] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com