Electrochromic material as well as preparation method and application thereof

An electrochromic material and material layer technology are applied in the field of electrochromic materials and their preparation to achieve the effects of convenient electronic access, improved electron transport performance, and easy large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A kind of preparation of electrochromic material, comprises the steps:

[0057] 1) Polish the platinum sheet with 2000-mesh sandpaper, clean it with a mixture of dichromic acid, rinse it with deionized water and absolute ethanol, and use it as a counter electrode;

[0058] Saturated calomel electrode was wiped clean with deionized water and ethanol as a reference electrode;

[0059] ITO glass was ultrasonicated for 15 min each in acetone, absolute ethanol, and deionized water, and dried as a working electrode.

[0060] 2) Weigh 0.0932g of zinc acetate and dissolve it in 100mL of deionized water to form a 5.0mmol / L zinc acetate solution;

[0061] Weigh 1.4910g potassium chloride and dissolve it in 100mL deionized water to make a 0.2mol / L potassium chloride solution;

[0062] Get above-mentioned zinc acetate solution and each 17.5mL of potassium chloride solution and mix, zinc acetate concentration after mixing is 2.5mmol / L, and potassium chloride concentration is 0.1mo...

Embodiment 2

[0071] A kind of preparation of electrochromic material, step is the same as embodiment 1, and difference is:

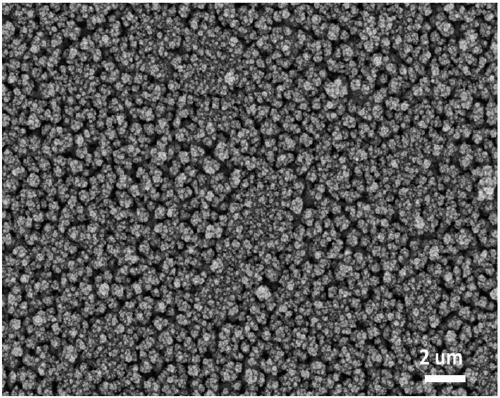

[0072] In the preparation of the ZnO nanorod array in step 2), a voltage of -1.0V.vs.SCE was applied for 100s to prepare the ZnO nanorod array. The length of the nanorods is 0.10 μm, the diameter is 0.10 μm, and the arrangement is sparse under the scanning electron microscope.

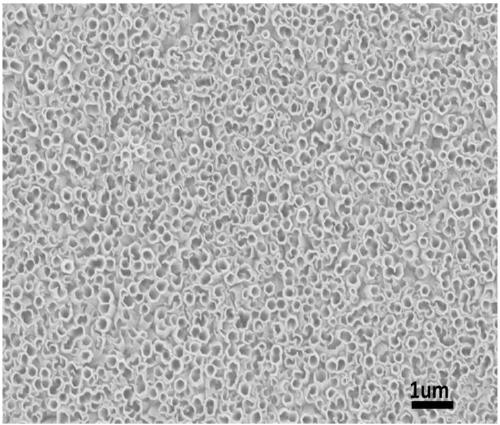

[0073] In step 5), apply a voltage of 1.0V.vs.SCE for 40s. The average thickness of the grown PEDOT is 1.40 μm, and the cross-section is observed through a scanning electron microscope, and the surface has certain undulations.

[0074] Carry out performance test to the prepared electrochromic material:

[0075] The method steps are the same as in Example 1, and the contrast ratio of the test is 10.16%.

Embodiment 3

[0077] A kind of preparation of electrochromic material, step is the same as embodiment 1, and difference is:

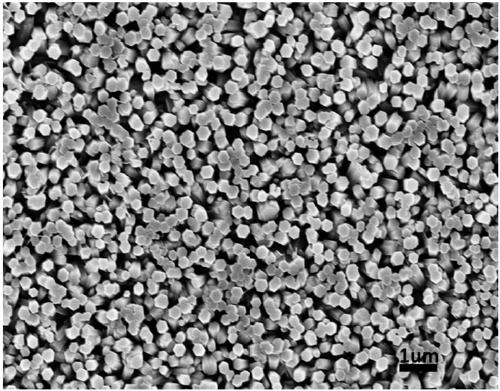

[0078] In the preparation of the ZnO nanorod array in step 2), a voltage of -1.0V.vs.SCE was applied for 4000s to prepare the ZnO nanorod array. Under the scanning electron microscope, the length is 1.50 μm, the diameter is 400 nm, and the array is neat and dense.

[0079] In step 5), apply a voltage of 1.0V.vs.SCE for 40s. The average thickness of the grown PEDOT is 1.60 μm, and the cross-section is observed through a scanning electron microscope, and the surface has certain undulations.

[0080] Carry out performance test to the prepared electrochromic material:

[0081] The method steps are the same as in Example 1, and the contrast ratio of the test is 12.55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average inner diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com