A kind of oxidation-resistant cerium-doped carbon quantum dots and its preparation method and application

A carbon quantum dot and cerium doping technology, applied in the fields of nanomaterials and medical engineering, can solve problems such as lack of research reports, and achieve the effects of broad application prospects, low equipment requirements, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this example, cerium-doped carbon quantum dots were prepared by the following steps:

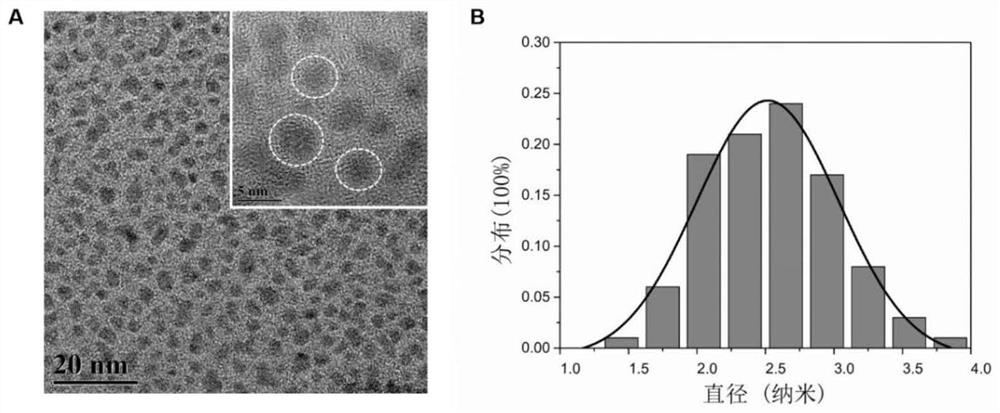

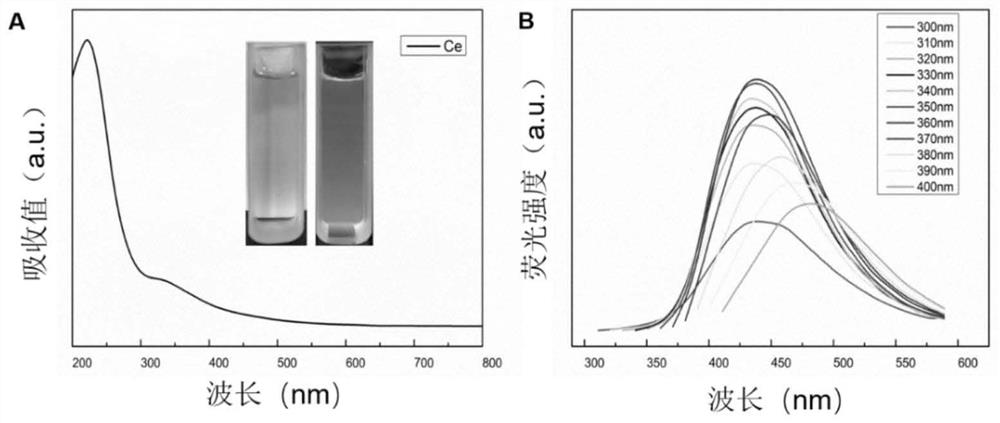

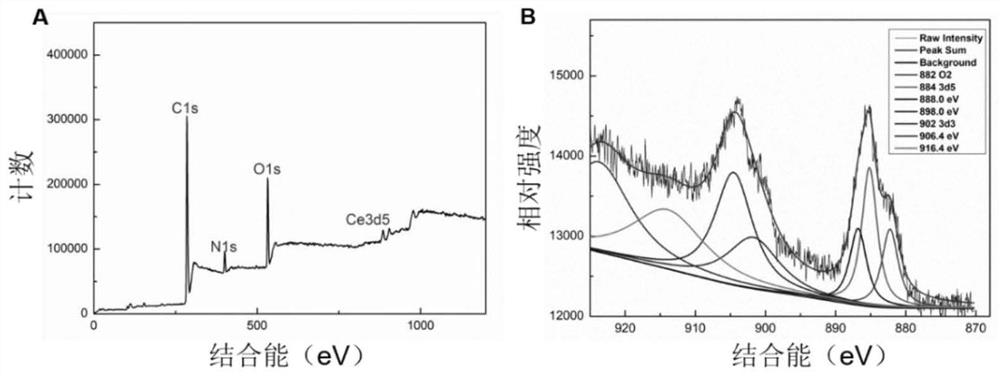

[0028] Dissolve 0.60 g of glycine, 0.84 g of citric acid, and 0.10 g of cerium nitrate hexahydrate in 20 mL of double-distilled water, and stir magnetically at room temperature to fully dissolve to obtain a uniform and transparent solution. Put the above solution into the reaction kettle to seal it, put it into an electric constant temperature vacuum oven, heat at 160°C for 4 hours, cool to room temperature to obtain a quantum dot solution, and centrifuge at 2000 rpm for 15 minutes to remove large particle precipitates. The collected supernatant was poured into a dialysis bag with a molecular cut-off of 1000 Da for dialysis. The dialysis time was 72 h, and the water was changed every 12 h. The dialysis product was freeze-dried in a freeze dryer at -80°C to a powder form to obtain cerium-doped carbon quantum dots.

Embodiment 2

[0030] Dissolve 0.75 g of glycine, 0.84 g of citric acid, and 0.10 g of cerium nitrate hexahydrate in 20 mL of double-distilled water, and stir magnetically at room temperature to fully dissolve to obtain a uniform and transparent solution. Put the above solution into the reaction kettle to seal it, put it into an electric constant temperature vacuum oven, heat at 200°C for 3 hours, cool to room temperature to obtain a quantum dot solution, and centrifuge at 2000 rpm for 15 minutes to remove large particle precipitates. The collected supernatant was injected into a dialysis bag with a molecular cut-off of 2000 Da for dialysis. The dialysis time was 72 h, and the water was changed every 12 h. The dialysis product was freeze-dried in a freeze dryer at -80 °C to powder to obtain cerium-doped carbon quantum dots.

Embodiment 3

[0032] Dissolve 0.90 g of glycine, 0.84 g of citric acid, and 0.10 g of cerium nitrate hexahydrate in 20 mL of double-distilled water, and stir magnetically at room temperature to fully dissolve to obtain a uniform and transparent solution. Put the above solution into the reaction kettle to seal it, put it into an electric constant temperature vacuum oven, heat at 200°C for 7 hours, cool to room temperature to obtain a quantum dot solution, and centrifuge at 2000 rpm for 15 minutes to remove large particle precipitates. The collected supernatant was injected into a dialysis bag with a molecular cut-off of 2000 Da for dialysis. The dialysis time was 72 h, and the water was changed every 12 h. The dialysis product was freeze-dried in a freeze dryer at -80 °C to powder to obtain cerium-doped carbon quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com