Coated mineral feed additive and preparation method thereof

A technology for mineral feed and feed additives, which is applied in the molding or processing of animal feed, animal feed, and additional food elements, etc., can solve the problems of inability to achieve sustained release, poor intestinal absorption, and poor palatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The coated mineral feed additive is composed of an inner layer, a binder, an outer layer and a coating layer; wherein, the inner layer is K 2 Mg[SO 4 ] 2 ·nH 2 0; the binder is common maltose syrup; the outer layer is potassium bicarbonate; the coating layer is an enteric-coating inclusion material hypromellose phthalate, ie HPMCP.

[0027] The feed additive comprises the following raw materials in parts by weight:

[0028]

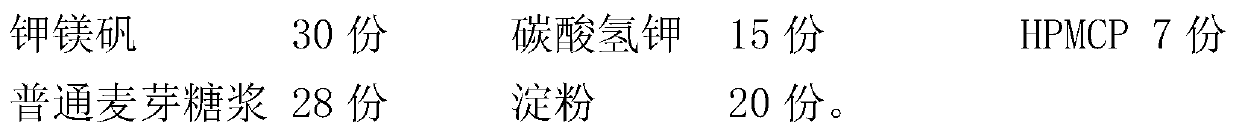

[0029] The preparation method of the coated mineral feed additive comprises the following steps:

[0030] ⑴Weigh 30 parts of potassium magnesium vanadium, 10 parts of starch and 20 parts of water to fully mix to make a paste mixture, put it into a swinging granulator to make wet granules, and pass through a 16-mesh sieve;

[0031] (2) Put the wet granules described in step (1) into 28 parts of ordinary maltose syrup and soak for 3 minutes;

[0032] (3) Take by weighing 15 parts of potassium bicarbonate, 10 parts of starch and 20 parts of wa...

Embodiment 2

[0038] In this case, the farrowing sows were grouped for a comparative feeding experiment. There were 480 sows in the experiment, with an average parity of 2.3, and they were randomly divided into the experimental group and the control group. The experimental group added 5kg / ton of full-price feed as in Example 1. The products mentioned in the above, the control group was common full-price feed, and other feeding conditions were the same. For a period of six months, the average daily feed intake of sows, the incidence of constipation during pregnancy, the average litter size, the average live piglet size, and the average weaning weight of piglets were recorded. The results are shown below.

[0039] group control group test group Average daily feed intake of sows (kg / day) 4.6 4.9 Incidence of constipation during pregnancy in sows (%) 62 14 average litter size 11.1 11.81 average live piglets 10.16 10.64 Average weaning weight of pigle...

Embodiment 3

[0041] The present embodiment adopts fattening pig grouping to carry out comparative feeding experiment, experiment fattening pig altogether 100, initial average body weight is 81kg, is divided into experimental group and control group at random, and experimental group adds 5kg / ton in the feed as in embodiment 1 Described product, control group is common feed, and other feeding conditions are identical. For a period of 21 days, the average daily weight gain, average daily feed intake and feed-to-meat ratio of the finishing pigs were recorded, and the results are shown below.

[0042] group control group test group Average daily gain, g 949.68±22.66 993.94±44.14 Average daily feed intake, g 3036.07±87.72 3097.96±115.96 average feed to meat ratio 3.20±0.12 3.14±0.21

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com