Enzyme-polymer complex capable of decontaminating nerve agents and preparation method and applications thereof

A technology of nerve agents and complexes, applied in the field of enzyme-polymer complexes, can solve the problems of slow decontamination efficiency and personnel poisoning death, and achieve the effects of no toxic side effects, high safety, and high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The synthesis of embodiment 1 DFPase-pDMAEMA

[0075] 1. Isolation and purification of DFPase

[0076] (1) Weigh 650g of fresh pork liver, put it into a flask, cut it into small pieces, and add distilled water to mix.

[0077] (2) Add 100ml of cell lysate therein to fully rupture the pig liver tissue cells.

[0078] (3) Homogenize in batches with a homogenizer, and collect a total of 2000 ml of homogenate.

[0079] (4) Centrifuge the homogenate (10000r / min, 20min, 4°C), collect the supernatant to obtain a total of 1500ml of supernatant A (suspension).

[0080] (5) Heat-treat the supernatant A. The collected supernatant was placed in a water bath at 60°C for 10 min, and then quickly cooled in ice cubes. Then it was centrifuged (10000r / min, 10min, 4°C) to remove denatured protein impurities, and 1175ml of supernatant B solution (red, clear) was collected.

[0081] (6) Filter the supernatant B to remove impurities. Aspirate liquid B with a 50ml needle, and press filt...

Embodiment 2

[0098] The synthesis of embodiment 2.DFPase-F127

[0099] (1) Weigh 5g of F127 and put it into a two-necked pear-shaped bottle with a volume of 50ml. The system is sealed, vacuumized and then filled with nitrogen. The subsequent reactions in the pear-shaped bottle are carried out in a system filled with nitrogen. Mix 15ml of 1,4-dioxane and 110μl of triethylamine, then add 97mg of DMAP to dissolve completely, inject the solution into the pear-shaped bottle with a syringe, and keep stirring (1000r / min, 90min).

[0100] (2) Slowly drop the succinic anhydride solution (99mg succinic anhydride dissolved in 5ml 1,4-dioxane) into the pear-shaped bottle through the constant pressure dropping funnel, and continue to stir at room temperature (1000r / min , 41h).

[0101] (3) After the stirring was stopped, the solution was transferred to a 100ml pear-shaped bottle (the solution was almost oily and colorless). Use a rotary evaporator to remove excess 1,4-dioxane by suspension steaming (...

Embodiment 3D

[0108] Physical evaluation of embodiment 3DFPase-F127 and DFPase-pDMAEMA

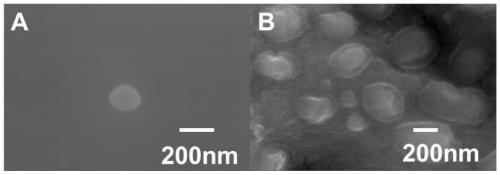

[0109] (1) Morphological characterization. Take a small amount (about 150-200μl) of DFPase-F127 and DFPase-pDMAEMA aqueous solution (the concentration of DFPase is 0.2mg / ml) and drop it on the silicon wafer, and let it dry naturally at room temperature. After drying, a layer of nano-gold layer is sprayed to enhance the conductivity of the sample, and the sample is observed under a scanning electron microscope (SEM), see figure 1 , it can be seen that the synthesized DFPase-F127 and DFPase-pDMAEMA are nanoparticles with a size of about 200-300nm.

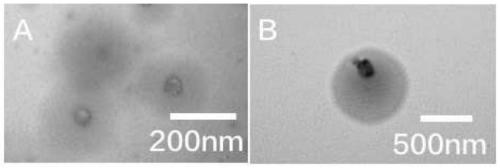

[0110] (2) Internal structure characterization. Take 50 μl of DFPase-F127 and DFPase-pDMAEMA aqueous solution (the concentration of DFPase is 0.2mg / ml) and drop it on the copper grid to air dry naturally. figure 2 , it can be seen that DFPase is a nearly round nanoparticle with a diameter of about 200-300nm; the density of the inner core of the nanopartic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com